Generally welders use oxyfuel combustible gas for shearing and welding even as it can be used for de-scaling cutting straightening and welding. If work cant be moved remove combustibles from area.

Safety During Gas Cutting Welding Safety In Gas Cutting Operation Ppt Download

Before attaching to cylinder.

Welding & gas cutting safety.ppt. Acetylene gas C2H2 is dissolved in acetone liquid and stored at 250 psi in a specially designed cylinder. Times New Roman Arial Wingdings Training 1_Training Oxyacetylene Welding Introduction 8 Steps to Making a Quality Weld Step 1 Safety Step 2 and 3 TIP Selection Setting the Gas Pressure Step 4 Ensure the Tip is Clean Step 5 - Set torch to Neutral Flame Step 6 Get Comfortable Mild Steel Welds Mild Steel Welds Factors Affecting the Weld Step 78 Coupling Distance and Torch Manipulation. Safety in Welding and Cutting Secretariat American Welding Society Abstract This standard covers all aspects of safety and health in the welding environment emphasizing oxygen gas and arc welding processes with some coverage given to resistance welding.

Dont allow untrained Welder or Gas Cutter. This leaflet is for people who use compressed gases for welding hot cutting and similar processes. Close cylinder valve Release gas from regulator.

Braze welding of heavy steel and cast iron. Prior to welding or cutting make sure you have clean air to breath or wear the proper respirator. Dont leave the gas cylinders valves open during lunch or tea breaks.

Valve 1926350a10 Oxygen cylinders in storage shall be separated from fuel-gas cylinders or combustible materialsespecially oil or grease a minimum distance of 20 feet 61 m or by a noncombustible barrier at least 5 feet 15 m high having a fire-resistance rating of at least one-half hour. It describes the hazards associated with portable oxyfuel gas equipment and the precautions for avoiding injury and damage to property. Safety in gas welding cutting and similar processes.

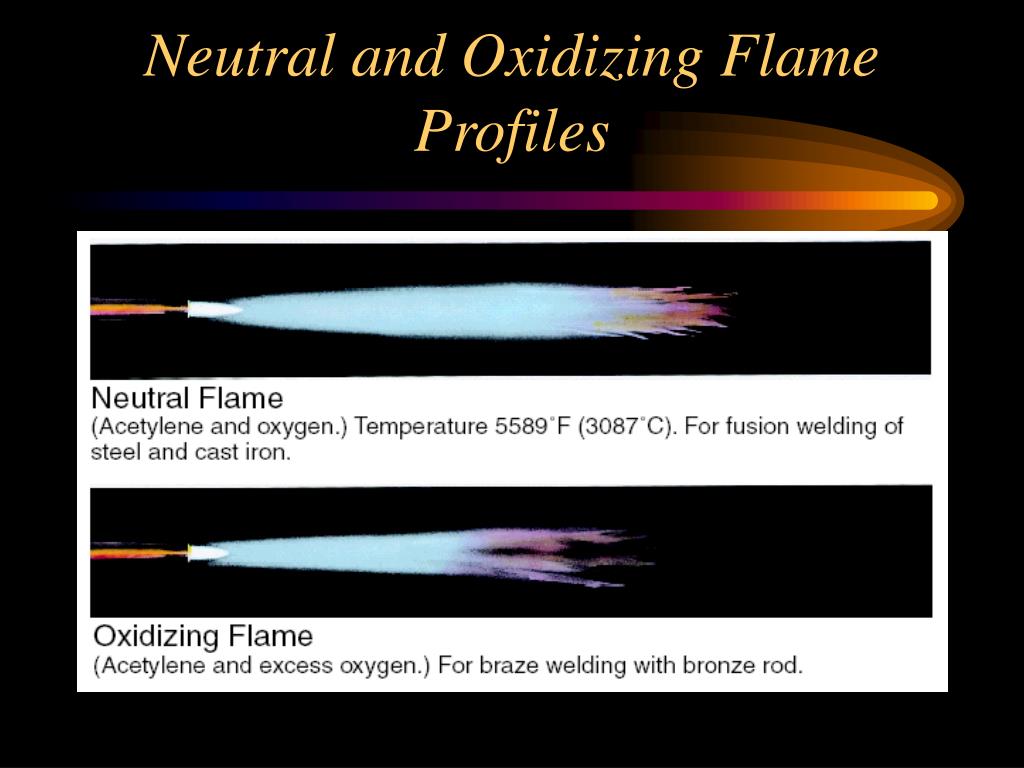

1926350a11 Inside of buildings cylinders shall be stored in a well-protected well-ventilated dry. Ventilation Securing cylinders and machinery Lifelines Electrode removal arc welding Gas cylinder shutoff gas welding cutting Warning signs for hot metal Health Protection Ventilation General requirements for protecting welders are based on 3 factors. Shade 5 Fusion welding of steel cast iron nickel and copper.

It describes the hazards associated with portable oxyfuel gas equipment and the precautions for avoiding. Braze welding of light copper and steel. Dont use bare electric cable.

Dont use damaged hose pipeWelding lead. Safe procedures for safe welding and cutting are extensive because the many hazards involved Common hazards include handling compressed gases and exposure to electricity fumes gases noise radiation fire and explosions. Protection of Personnel Work in confined spaces requires consideration of.

Move work to a safe place. When welding or cutting welding goggles must be worn. 21 This Safety Code provides safety guidelines in carrying out gas cutting or heating by gas and gas welding work at site while taking up fabrication maintenance and manufacturing jobs in iron steel industry.

It contains information on. Avoid breathing these fumes and gases. Welding and cutting iron sheets and rods using compressed gases can be dangerous unless the welder is aware of safety measures to prevent a possible accident.

See ANSI Z491 1967 Safety in Welding and Cutting published by the American Welding Society. Keep fire extinguishers handy and be fully knowledgeable in its use. Adequate exhaust ventilation must be used when using inert-gas welding plasma-arc cutting or carbon-arc cutting.

Before removing from cylinder. Welding may produce fumes and gases hazardous to health. 3 PROCEDURE 31 The activity of gas cutting or heating by gas and gas welding work involves following preliminary actions to avoid accidents.

3 safety in welding-31 hazards-. WELDING AND CUTTING SAFETYYAWAR HASSAN KHAN 2. Stand to one side of cylinder outlet Open valve slightly then close Never use Teflon tape on a CGA fitting.

ACETYLENE CYLINDERS Maroon in colour. 22 The scope does not cover arc welding work. Never attempt to repair or modify a regulator.

Gas Cutting Welding Gas Cutting Welding PPREPARED BY SOUMEN MAKAR RECLAMATION AND DREDGING WORKS BMCTJNPT-4. Dimensions of space especially ceiling height in which welding is to be done Number of welders. Acetylene cylinders has a volume of 85 m3.

12 oxygen cylinder-13 cylinder storage-14 regulators-15 unloading from truck-16 lifting cylinders by crane-17 use of cylinder trolley-18 right operation-19 hazards in gas cutting-110 a fire on cylinder-2 ppe for safety in gas cutting and welding. Welding and Cutting for construction Welding safety program guidelines Person responsible Accountability and enforcement Job hazard assessment Special procedures Welding safety program guidelines Engineering controls Administrative controls Personal protective equipment Welding safety program guidelines Equipment inspectionmaintenance Near miss investigation Compressed gas cylinders hazards Valve protection caps Hoisting cylinders Moving cylinders Compressed gas. Approved personal protective equipment PPE shall be worn by all employees performing or.

Dont cut or weld in the presence of flammable liquids or vapors in the presence of lint or dust or on. Gas cutting welding1. GAS WELDING AND CUTTING Oxy-fuel welding commonly referred to as oxy welding or gas welding is a process of joining metals by application of heat created by gas flame.

The metal surface shall be free of all chlorinated solvents during any welding or cutting operations. Shade 4 Oxy-cutting and gouging. Welding and cutting safety 1.

INDG297rev1 Download a free copy - INDG297. 1 safety in gas cutting and welding. To Prevent Cutting or Welding Fires.

The fuel gas commonly acetylene when mixed with proper proportion of oxygen in a mixing chamber of welding torch produces a very hot flame of about 5700-5800F. Do not leave electric circuits on or blow-torches burning when the welder has to take a tea break or has to be away for any reason. Safety in gas welding cutting and similar processes This leaflet is for people who use compressed gases for welding hot cutting and similar processes.

Ppt Welding And Cutting Safety Powerpoint Presentation Free Download Id 508153

Nsc Welding And Gas Cutting Welding Construction

Ppt Welding And Cutting Safety Powerpoint Presentation Free Download Id 508153

Ppt Unit Oxy Fuel Welding Brazing Cutting And Heating Powerpoint Presentation Id 6110361

Safety During Gas Cutting Welding Safety In Gas Cutting Operation Ppt Download

Gas Welding And Cutting Safety Authorstream

0 comments:

Post a Comment