Weld on galvanized steel. You can weld galvanized steel with flux core wire.

How To Weld Galvanized Steel 13 Steps Wikihow

Any Arc Welding Process General Recommendations The best way to weld galvanized steel regardless of welding process is to remove the zinc coating from the joint.

How to arc weld galvanised steel. However zinc coating produces extremely toxic fumes that must be vented away. Stick arc welding is best used on heavy metal and so can be used just as effectively as MIG on galvanized steel. Removing the coating and re-spraying or painting the weld seam after welding to regain corrosion resistance.

1Manual arc welding 1 Weld preparation. However it still holds its place. Protective gear and proper ventilation are essential to welding galvanized steel safely.

Welding Galvanized Steel by SMAW MMAW. Comments section says maybe only a couple of minutes is required to remove the Galveston and not the 24hrs or so he used. Removing the coating and re-spraying or painting the weld seam after welding to.

The most common and preferred removal method is grinding back the zinc coating but burning the zinc away or pushing it back from the weld area are also effective. Typically the arc gap should be no greater than the electrode diameter. Oct 1 2017.

The controlled fine droplet spray transfer produced by pulsed GMAW results in a more stable arc than with short-circuiting so more joint types and a wider range of material thicknesses can be joined. By reducing spatter it increases process efficiency and minimizes cleanup. If you cant do this use a filler material on the zinc-coated portion of your welding area.

The welding conditions necessary for galvanized steel welding by SMAW and MMAW are similar to those used on uncoated steel. The zinc coating should be removed at least 1-4 inches from either side of the intended weld and on both sides of the workpiece. Best Practice Guide for Welding Hot Dip Galvanized Steel Edition 1 February 2019 Introduction 1 Best practice welding of uncoated steel 1 Appearance of the welded area 1 Chemistry of the welding rod 1 Managing weld splatter 2 Removing welding slag 2 Welding overlapped surfaces 3 Welding to minimise distortion in the galvanizing process 3.

Galvanized steel can be welded by manual electric arc welding melting electrode gas shielded welding argon arc welding resistance welding etc. All welds on galvanized surfaces destroy the zinc coatings at the weld site and damage the coating adjacent to the weld. For galvanized steel a standard arc welder is probably the best way since arc welding is versatile and the alternating currents allow you to create a good arc that can melt the flux quickly.

Used commonly in construction the stick welding technique has gradually been replaced by MIG. Welding of thinner gauge galvanized steel can be done using direct current electrode negative straight polarity 116 diameter EWTh-2 tungsten pencil-sharpened with a 132 flat end ER70S-2 or ER70S-3 filler metal argon shielding gas and the following parameters. Both basic and rutile coated electrodes can be used but simple procedural tests should be made before undertaking production welding.

This adds two operations. Practice steadying the arc by holding the electrode about 18 to 316 of an inch from the work piece then begin moving along the path you want to weld. It works by creating a high heat and melting the electrode and metal creating the weld.

A short arc length gives better control of the weld pool and helps to prevent either intermittent excess penetration or undercut. As you move the electrode the metal will be melting away filling the pool of molten metal and building your weld. Any Arc Welding Process General Recommendations The best way to weld galvanized steel regardless of welding process is to remove the zinc coating from the joint.

As you know welding requires a high level of patience and skill. Pulsed metal transfer GMAW can help improve galvanized steel weld quality even more. Seems like a fairly safe and convenient way to remove the half including hard to grind areas.

Grinding is the most effective means of removing galvanized coating. Contacts us for information on welding galvanised steel. You will need a skilled welder to weld galvanized steel successfully and the ideal method is to remove the zinc coating from the area where you are welding.

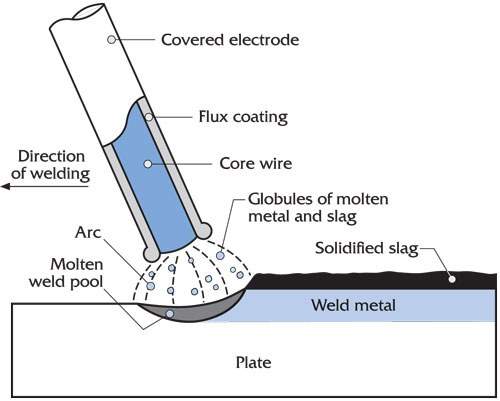

This adds two operations. Welding galvanized steel should always be done in well-ventilated locations to minimize fume inhalation. Both Shielded Metal Arc Welding SMAW or Manual Metal Arc Welding MMAW for welding galvanized steel are manual processes using flux-covered electrodes of 16 mm to 127 mm in diameter.

I saw this from ChuckE recently using hydrochloric acid to remove the galv. Arc welding sometimes creates flux so you may want to work outside if possible.

Welding Galvanized Steel American Galvanizers Association

Stick Welding Square Tube Youtube

Will Galvanized Steel Pipes Be Welded

How To Weld Galvanized Steel Welding Answers

How To Weld Galvanized Steel Welding Answers

How To Weld Galvanized Steel 13 Steps Wikihow

How To Weld Galvanized Steel Welding Answers

Welding Galvanized Steel Hiqh Quality Welds Welding Galvanized Metal

How To Weld A Galvanized Steel Welding Hub

0 comments:

Post a Comment