You dont want to hard roll before welding. All work areas must be thoroughly cleaned.

Useful Tips For Titanium Tube Welding Process Titanium Metal

Its best to use chemicals specifically designed for titanium.

How to clean titanium before welding. Sandblasted using 50 µm silicon dioxide SiO2 straps at 25 psi to create dull surfaces to reduce laser beam reflection during laser welding. It is recommended that before welding the arc is struck on a scrap piece of titanium termed titanium-getter to remove oxygen from the atmosphere. The oxygen level should be reduced to approximately 40ppm before striking the arc on the scrap titanium and.

Cleaning large areas too early before welding often leads to the need for rework. Acetone is the best solvent to use. To remove the last remaining organic compounds just before welding use a lint-free glove and methyl alcohol acetone or other chlorine-free solvent.

Steam cleaning or an alkali dip in a dilute solution of sodium hydroxide can remove most of these contaminants. With metals such as aluminum and titanium there is a shorter window of time between the surface cleaning and the welding as oxidation can form very quickly. Nonferrous materials present their own challenges in the weld preparation process.

Titanium has to be very clean from oil grease coatings and oxides before welding takes place. Any cracked or contaminated tack welds must be removed before final welding. Be Sure to Properly Shield Gas When heated titanium becomes highly reactive and readily combines with oxygen nitrogen hydrogen and carbon to form oxides.

Follow that up with the cleaning process. All titanium welds to prevent contamination. Stay away from canned degreasers because they can contain chlorinated solvents that are really bad for titanium.

This requires the use of inert gas which could be helium but is usually argon. All work components should be considered for cleaning depending upon the welding method. Clean the outside of the titanium tubing by using a stainless-steel brush and when welding it is recommended to use the dab technique to help bolster the mass of the pipe.

There are additional considerations for shielding gas when GTA welding titanium including back purging and the. However to adequately clean up the surface we recommend using titanium specific chemical cleaners. We recommend observing the three Cs of cleaning before welding.

Cleaning Before welding titanium it is important that weld joints and weld wire be free of mill scale dirt dust grease oil moisture and other potential contaminants. Clean the surface of the titanium to eliminate any impurities and remove any oil grease or dirt. The tube and hole had better be very clean when they go.

Cleanliness is another important factor when welding titanium. To do that use a grinder and a deburring tool. Make sure to reserve both tools for titanium specifically.

To remove the contaminants you can use a steam cleaner or a diluted solution of sodium hydroxide. Titanium welders must master the techniques and tools required to shield welds from oxygen. You will have blow hole issues in the welds.

Oil or grease will cause porosity like you see in this x-ray negative of a. The welding tungsten should be clean and new and not be contaminated by the welding of other materials on previous work. Prior to making production welds on titanium procedures and techniques should be closely evaluated.

Before welding make sure you break down the oxide layer on titanium. See Table 1 for a more complete listing of recommended cleaning media and proper inhibitor additions. Nitric acid is an excellent passivating agent for titanium and may be used alone or with hydrochloric acid to clean titanium surfaces.

Clean the filler rod. Failure to properly clean any of the above surfaces can lead to contamination of your work piece. Titanium welders have to shield not just the liquid weld pool but also the surrounding metal.

Then cleaned using Acetone solution to remove any oil attached for 5 min as recommended by the American Welding Society and dried with nitrogen gas to be ready for welding. When you do hard roll you have to stay at least 18 back from the weld and the same or more in from the back face to the tubesheet. Any titanium filler rod material should be thoroughly checked for cleanliness.

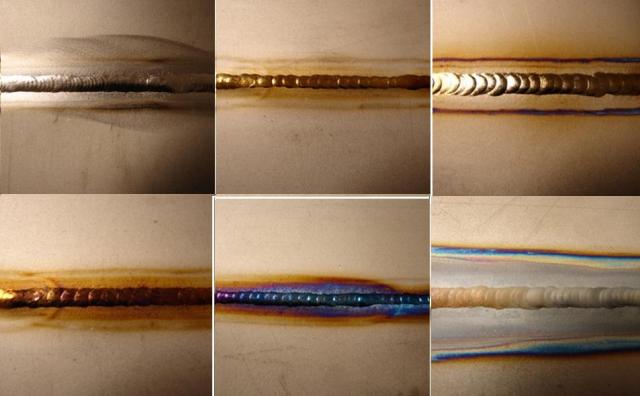

Contaminated weld beads as evidenced by a dark blue grey or white powdery colour must be completely removed by grinding. Use a plastic hose to transport the shielding gas as a rubber hose can allow oxygen to mix with the shielding gas and contaminate the weld. Although titanium is a highly reactive material which should be protected from air contamination when hot there is no need to employ inert gas for cold welding or when spot or seam welding but the metal should always be clean and the electrodes must be thoroughly water cooled.

Any contamination by materials that are vaporized by the heat of welding dirt oils grease finger prints paint etc will freely enter the molten weld puddle and contaminate the weld and base metal. Remember that the cleaner the titanium will be the stronger your created weld will be. It needs to be completely clean and free from oil grease paint or anything else.

Typical cleaning solutions for titanium equipment. The joint must then be carefully prepared and cleaned before welding again. Titanium welds very nicely if it is properly cleaned and purged.

Inclusion of these foreign substances in. Sometimes a light roll is used to control the weld gap.

Welding Titanium Tips And Tricks

Welding Titanium Tips And Tricks

How To Weld Titanium Tips And Tricks Welder Portal

Suppressors Welding Titanium Sniper S Hide Forum

Welding Titanium Tips And Tricks

Tips For Welding Titanium The Joe Electrode Blog

Welding Of Titanium And Titanium Alloys

Welding Titanium Tips And Tricks

0 comments:

Post a Comment