At the same time it is necessary to reach a temperature of 700 degrees Celsius. The technique for mig welding bronze sculptures is fairly simple.

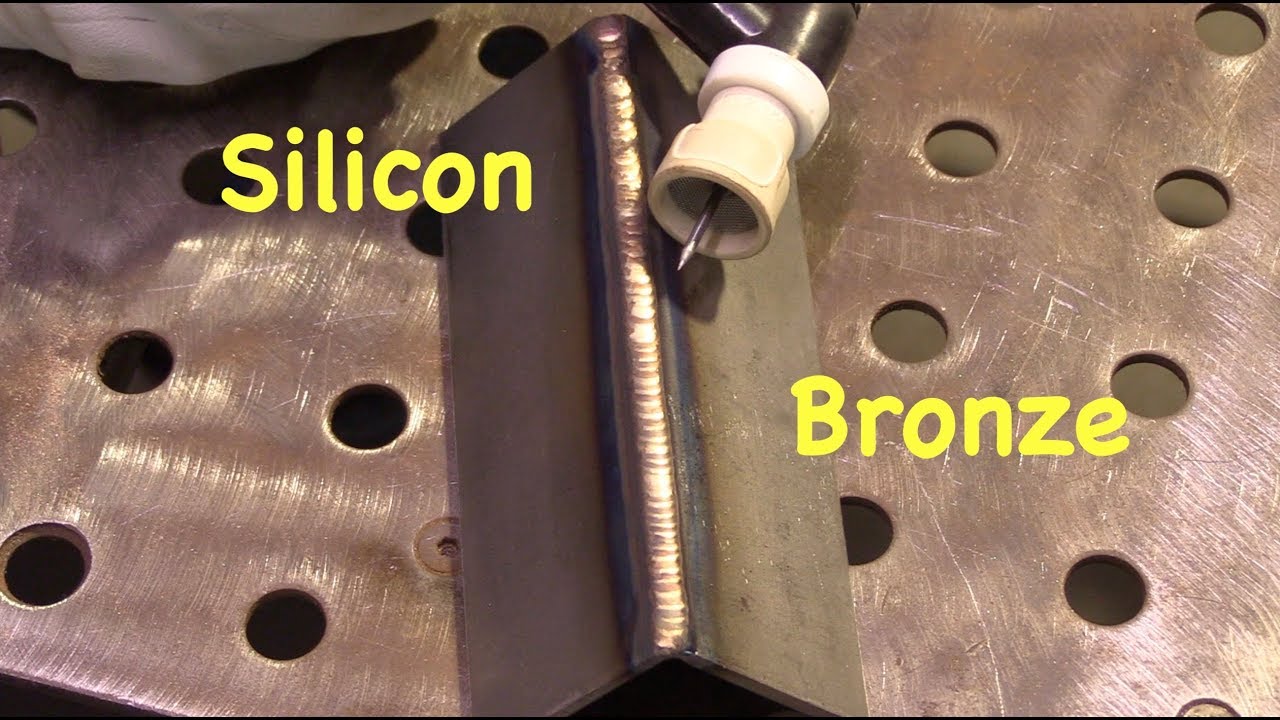

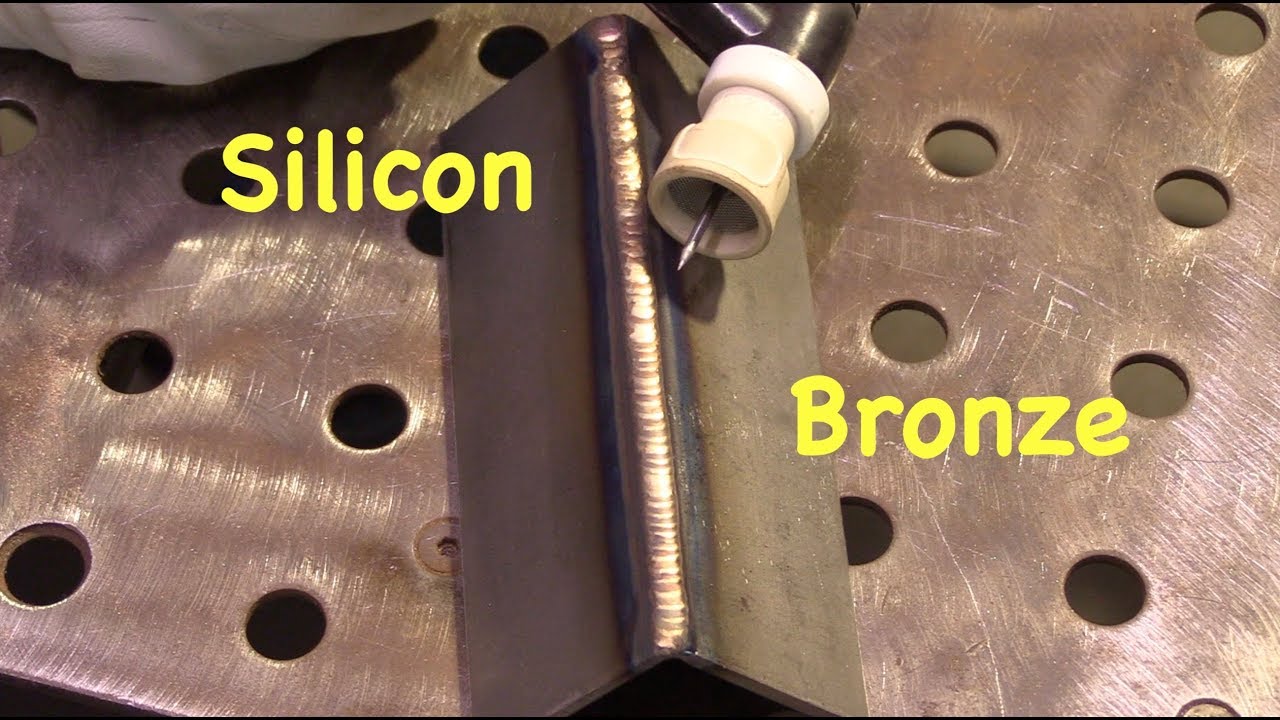

Sp 5 Silicon Bronze Mig Brazing Youtube

I generally expect a little base metal melting at the start but after that you should be able to control it pretty well.

How to do bronze welding. They contain between 10 and 40 silicon with small amounts less than 15 in total of zinc manganese andor iron. Set the flow rate to around 20-25 cubic feet an hour and make sure that the gas is switched on. Architectural Bronze is a broad term that can be used to describe a variety of slightly different alloys.

The best way to find a good color match for the weld is to do a sample. It is also very important to monitor the operation of the burner. The filler rod is broader than that used in brazing.

The scheme of high-temperature soldering of bronze. Wait 1 second for the red glow to subside then start the next bead 12 back to overlap where it was melting through and do another 1 bead. 1 - torch movement.

It flows onto the two surfaces forming a fillet around the joint joining the two surfaces. Mig welding bronze is messier than Tig welding is and there is less control and thus requires more chasing grinding and chiselling. Silicon bronzes are probably the easiest of all the bronzes to weld.

Also this would be tig brazing and not welding. A stringer bead welding technique is generally necessary and heavy sections require preheat and interpass temperatures of around 200C. This means they may have slight differences in color depending on the supplier.

Welding and Brazing which have been used globally for almost a century. This is easy MIG welding techniques require you to use a reverse polarity DC electrode positivity on some machines. Braze bronze welding provides a strong joint and is ideal of steel frames where a certain amount of flexibility is required.

In one second I can do a one inch bead with the last 14 inch starting to melt through. Youll find these settings typically on the interior of the machine. The pick-up by the braze metal of impurity elements such as phosphorus and sulphur from the casting is minimised since the parent material is not melted.

MIG welding is great for welding carbon steel stainless steel aluminum magnesium copper nickel silicon bronze and other alloys. Its also possible to weld the sculpture parts with bronze wire in a Mig welder metal inert gas. Then choose your gas flow.

Instructables Theres a range of filler metals that are used such as copper phosphor bronze red brass yellow brass nickel silver aluminum bronze silicon bronze and coppernickel. 2 - bar movement. Braze welding involves introducing a filler metal which melts at a lower temperature than the iron eg.

Of course youll melt the base metal a little bit from time to time but try to melt as little as possible. Techniques for welding Ni-Al bronzes Gas shielded techniques such as TIG or gas tungsten arc welding GTAW and MIG or gas metal arc welding GMAW are the recommended methods for joining these materials. Sifbronzing For successful bronze welding or sifbronzing parts must be clean and for optimum strength a 60 90 vee preparation is required.

Using these materials ensure the best chance of a good color match in the weld. Brass brazing rod or cut pieces of the cap rail are generally used as the filler material. Using leftward welding technique the parts should be heated with an oxidising flame to a dull red.

3 - movement of the burner and rod. These methods limit the oxidation of the weld pool and by the action of the arc disperse surface oxide. Mig Welding Bronze Technique.

Alloys based on brass which have liquidus temperatures of 800-940C. TIG welding is frequently used to join the bronze cap rail sections together. In this case the metal wire filler and the gas are supplied by the one hand-piece.

Tried Some Silicon Bronze Tig Brazing Today It Went Okay And I Never Want To Do It Again Welding

Best Weld Color Match For Architectural Bronze Fusion Metals

Silicon Bronze Tig Brazing Youtube

![]()

Tig Welding Brazing With Silicon Bronze

Braze Welding Bronze Welding And Brazing Oxyacetylene

Adventures In Tig Brazing Youtube

Tig Brazing With Silicon Bronze

How To Weld Bronze 12 Steps With Pictures Wikihow

Using Silicone Bronze With Tig Mig Welding Forum

0 comments:

Post a Comment