Overexposure to welding fumes may result in symptoms like metal fume fever dizziness nausea dryness or irritation of the nose throat or eyes. See Section 8 for Exposure Limits of the oxides found in the welding fumes.

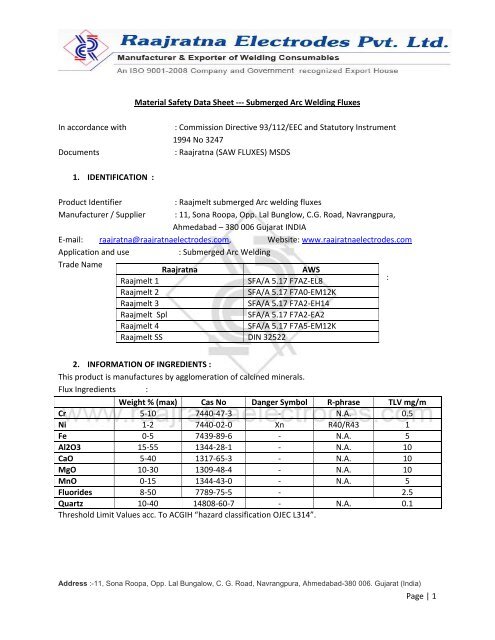

May aggravate pre-existing respiratory problems eg.

Msds for welding fumes. Dust and fume may be generated during fabrication eg. Pre-existing respiratory issues may be aggregated. Minimum flushing is for 15 minutes.

Manganese overexposure can affect the central nervous system resulting in impaired speech and movement. Chronic overexposure to welding fumes may affect pulmonary function. Read and understand the manufacturers instructions Safety Data Sheets and the precautionary labels before using this product.

Welding arc and sparks can ignite combustibles. Label and MSDS to health professional with victim. This MSDS is written for workers using these electrodes.

See Z-491 referenced in section VI SECTION V- REACTIVITY DATA Hazardous Decomposition Products Welding fumes and gases cannot be classified simply. Long-term chronic over-exposure to welding fumes can lead. Always use adequate ventilation.

Remove contaminated clothes and rinse skin thoroughly with water. During welding cutting and grinding see section 8. Arc welding and associated processes can kill.

Overexposure to welding fumes and gases can be hazardous. WELDING FUMES may result in discomfort such as dizziness nausea or dryness or irritation of the nose throat or eyes. Symptoms of metal fume fever which resemble influenza usually occur several hours after exposure and include a.

Cutting and Welding Processes published by the National Fire Protection Association Battery march Park Quincy MA 02269 for additional fire prevention and protection information. The risk from welding fumes should be eliminated or minimised by suitable selection of. When these products are used during welding or brazing operations follow the requirements of the Federal Occupational Safety and Health Welding and Cutting Standard 29 CFR 1910 Subpart Q and the safety standards of the American National.

Welding process welding parameters ventilationextraction and finally PPE. MATERIAL SAFETY DATA SHEET MSDS For Welding Consumables and Related Products Conforms to OSHA Hazard Communication Standard 29CFR 19101200. Flame cutting or welding fumes will contain also oxides of iron and other constituent metals.

No fumes or gases are evolved by ARC MIG TIG or GAS consumables at normal ambient temperatures but in use welding fumes will be evolved. Inhalation of welding fumesDust inhalation. Prolonged inhalation of nickel and chromium compounds above safe exposure limits can cause cancer.

Always use appropriate personal protective equipment. Dust from grinding or machining will have the same composition as the preparation. The welding arc can injure eyes and burn skin.

MSDS Welding Electrodes Page 4 of 4 010916 Rev1 result in loss of appetite weight loss loss of muscle coordination difficulty in breathing and anemia. PRIMARY ROUTES OF ENTRY. If fumes generated by welding operations involving this product contaminate the skin begin decontamination with running water.

Avoid breathing welding fumes and gases. The tables accompanying this leaflet give the chemical composition of the particulate fume evolved during use of the range of welding consumables analysis being of fume generated in an enclosed Swedish. Standard Must Be Consulted for Specific Requirements.

In case of persistent throat irritation or coughing. Long term overexposure to welding fumes can lead to siderosis iron deposits in lung and may affect pulmonary function. The primary entry route for welding fumes and gases is by inhalation Bronchitis and some lung fibrosis have been reported.

Avoid breathing fumes of these products during welding or brazing operations. Short-term acute overexposure to welding fumes may result in discomfort such as metal fume fever dizziness nausea dryness or irritation of nose throat or eyes. They may be dangerous to your health.

Fumes and gases 7 Short term effects Metal fume fever Metal fume fever occurs in welders who inhale zinc oxide fumes although other components for example copper aluminium and magnesium may also produce this condition. Substances formed under the conditions of use. _____ Section V Health Hazard Data_____ Welding fumes and gases can be dangerous to your health.

Ensure sufficient ventilation and exhaust at the arc to keep welding fumes and gases away from the welders breathing zone. The welding fume produced from this welding electrode may contain the. Move into fresh air and keep at rest.

The fumes emitted by the electrodes in use are hazardous. Short-term acute overexposure to fumes and gases from welding and allied processes may result in discomfort such as metal fume fever dizziness nausea or dryness or irritation of nose throat or eyes. Silica Amorphous-Research indicates that silica is present in welding fume in the amorphous.

Respiratory System eyes andor skin. Keep work area and protective clothing clean and dry. If molten material contaminates the skin immediately begin decontamination with cold running water.

Seek medical attention and bring these instructions. The composition and quantity of these fumes and gases are dependent upon the metal being welded the procedures. Refer to Section 8.

1 Material Safety Data Sheet Submerged Arc Welding Fluxes In

Material Safety Data Sheet Manualzz

Http Www Project Welding Com Download Php Fid 958

Http Www Harrisproductsgroup Com Media Files Pdf Sds Welding Aluminum Alloy 26 Aluminum Electrode 1 8 Pdf

Superinox 2c Msds Ador Welding Personal Protective Equipment Chromium

Https Www Hilco Welding Com Dk Webshop Amfile File Download File 713 Product 192

Https Nikkosteel Co Id Uploads Ed 7post File 2 2019 12 10 112949 Pdf

0 comments:

Post a Comment