C25 Shielding Gas The bottom line on operating cost shows that a C25 MIG mix is around 45 times more costly to weld with than a straight C100 gas. But Make sure to take into account the different variables while selecting the flow rate.

Oil And Gas Stock Prices Mig Welding Gas Flow Rate

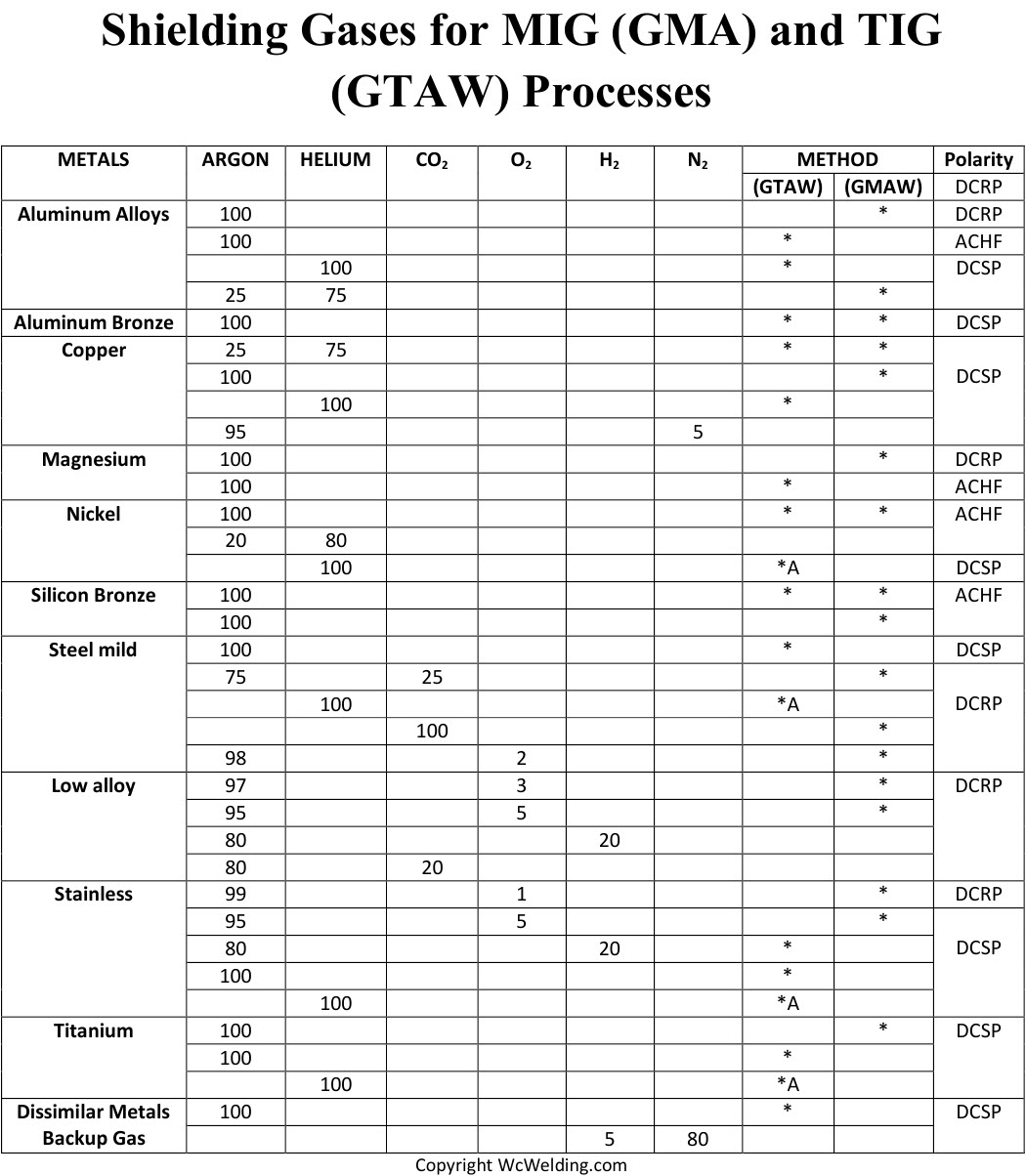

Shielding gases for TIGGTAW welding.

Shielding gas for mig welding cost. However we get into trouble because you can make welds look good regardless of what gas you use for the most part. On the surface MIG Welding with solid wire has a lower operating cost. Its not the cheapest of gas mixes but its well liked because it gives you the person MIG welding at home a nice balance between cost and attractiveness of the finished weld.

Inert gas is used for MIG welding or metal inert gas welding use inert gas as a shielding gas. Helium He can be added to increase penetration and fluidity of the weld pool. Mostly liquid while under pressure each pound yields 8741 cf of gas.

And remember your Argon Carbon Dioxide gas mix just like pure Argon gas wont go off. For instance the addition of hydrogen gives a similar but much stronger. The correct gas flow rate in MIG welding ranges between 15 to 25 CFH.

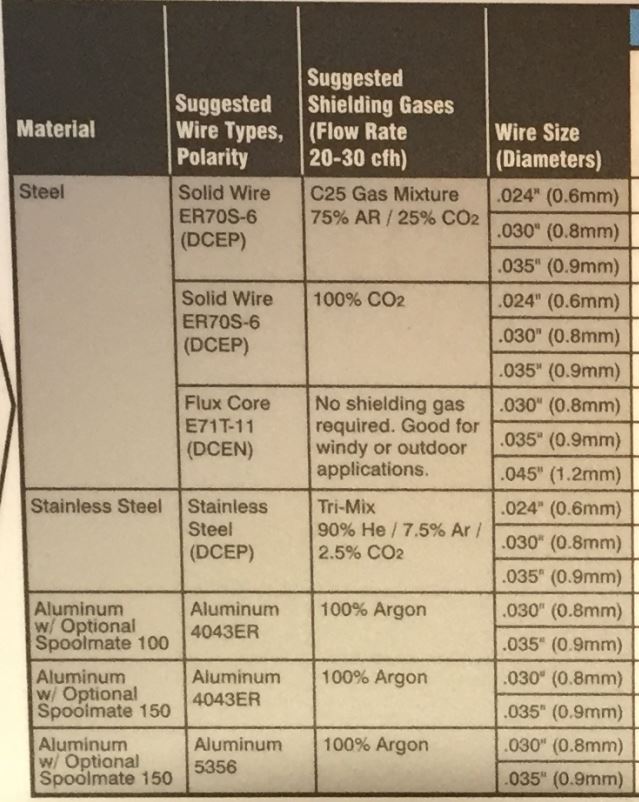

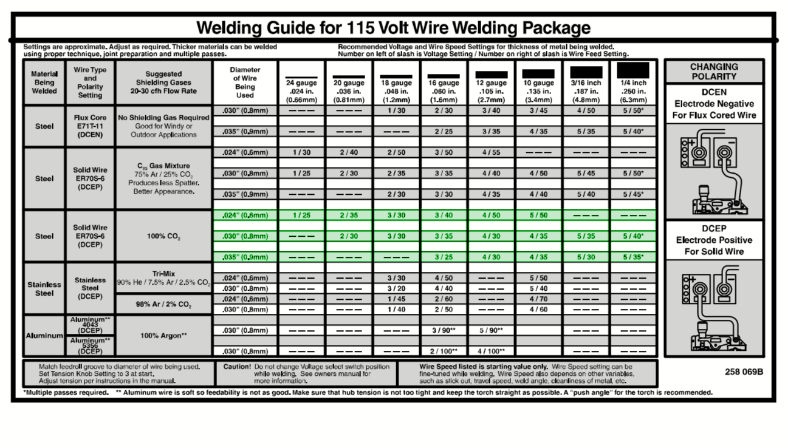

When starting it is important to make sure the gas. Also take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas. In some cases nitrogen N 2 andor hydrogen H 2 can be added to achieve special properties.

Argon or argonhelium mixtures can be used for welding all grades. Ad Find China Manufacturers Of Mig Welding. The typical gas pressure when welding with MIG tends to be around 3 to 8 psi this is very low compared to other types of welding.

The shielding gas provides the gas needed for MIG welding. For welding a non-ferrous metals like aluminum magnesium or titanium 100 argon is the way to go. 75 Argon 25 Carbon Dioxide 7525 90 Argon 10 Carbon Dioxide 9010 95 Argon 5 Oxygen 955 And many other mixtures.

The normal gas for TIG welding is argon Ar. In general you can expect to spend 150 to 350 dollars on a new full tank of shielding gas. The most commonly used shielding gas for home and hobby MIG welding is C25 75 Argon gas and 25 Carbon Dioxide.

Ad Find China Manufacturers Of Mig Welding. A bottle of MIG welder shielding gas varies in costs. There are a lot of gases that you can use for MIG welding and they can be further mixed together to create different qualities and properties.

For beginners youll want to start with mild steel and in order to weld that youll need a 7525 gas which is a mixture of 75 oxygen and 25 CO2. CO2 is much cheaper than inert gas and it allows the bond to penetrate very deeply into the metal when welding. Want to find out more about 7525 Argon CO2 tank sizes for Mild Steel welding.

Shielding gases are used in certain welding processes and are composed of inert gas andor semi-inert gas. Then click the link text to hop on over to a document all about it. However it has a much harsher arc that can be more difficult to control and its semi-inert nature leads to more weld spattering so the weld requires more cleanup compared to a noble gas.

For this reason automotive enthusiasts who are primarily welding on thin sheet metal prefer MIG Welding with solid wire and a shielding gas. The most reactive gas for MIG welding gas. For example 40 CF Argon 7525 CO2 costs roughly 150-170.

For example you can weld mild steel with any of the following shielding gases. Spec sUse Cost C100 vs. It depends on the amount and type of gas.

But dont be fooled as this is. Now that you have a good understanding of how much gas you should use as your welding with MIG you. A 7525 MIG Argon and CO2 mix is the most popular gas for MIG welding sales making up more than 90 of the gas we sell at Vern Lewis Welding Supply.

Hence there is less chance of burn through. Argon and Helium bottles are expensive and can cost up to 350 per cylinder. Argon CO2 helium and oxygen are the four most common MIG welding gases for shielding each with its own advantages and disadvantages.

The shielding gas prevents unwanted contaminants like oxygen and nitrogen in the air from entering your welding area. Because of the cheaper cost per cubic foot when you refill. 3 What gas should you use a beginner.

As the wire melts it burns the flux at the core of the wire creating a shielding gas around the weld.

Mig Welding Gases Choices And Options For Most Metals Gowelding Org

What Gas Is Used For Mig Welding A Complete Guide

Gas Shielded Arc Welding Processes Tig Mig Mag Openlearn Open University

Pdf Systematic Study Of Effect Of Cross Drafts And Nozzle Diamter On Shield Gas Coverage In Mig Welding

Pdf Study Of Shielded Gases For Mig Welding

Mig Welding With 100 Co2 Shielding Gas Welditu

0 comments:

Post a Comment