Trusted China Suppliers Verified by SGS. In the Calculation tab enter input parameters.

Schematic Image Of Fracture Modes In Resistance Spot Welding A If Download Scientific Diagram

Materials Data For Resistance Spot Welding.

Spot welding force calculation. The method of calculation is given as well as a mathematical solution tool. It is a condition that is specified is some quality plans AWS D87 Recommended Practices for Automotive Weld Quality- Resistance Spot Welding. Be alert that welding sparks can easily go through small cracks and.

Spot welding according to Joules law is expressed by the Equation. Conversion factor of weld joint -. Excessive weld indentation can cause rejected product.

If this is not possible tightly cover them with approved covers. Energy J Calculation for AC spot welding P. Diameter of spot weld mm in i.

For welding of the assembly consisting of two specimens of different thickness the spot welder type BV 2521 was used. Plate thickness mm in α. Melting energy Jmm3 S.

Typically a body shop welds steel between 16 gauge and 24 gauge. Result values are displayed in the Results area on the right side of the Calculation tab. H I2Rt where H Heat is generated in joules I Current in amperes R Resistance in ohms t Time to current flow in seconds Resistance Spot Welding Parameters The spot welding process parameters have their own importance.

Power W tw. Weld time sec 0241 2 w 2 where I. Do not spot weld where flying sparks can strike flammable material.

If a spot welder has adjustable length tongs a pressure gauge should be used to properly set the pressure. The following equation and calculator will determine the single shear load stress of a spot weld. 4 a scanning of a spot-welded assembly from a Swedish automotive manufacturer is shown.

Also the scientific work considers the calculation of the energy of the capacitors for a spot welding apparatus using modern methods of numerical simulation and programming. The deviation between nominal and actual positions of the spot welds is in many cases quite large. A small change of one.

For a number of more closely analyzed spot welds the maximum deviation from. 1 where E. To reduce indentation one must reduce excessive forces and heat at the surface.

Acting force N lb d. Remove all flammables within 35 ft 107 m of the weld. 18 rows This method will give good-looking spot welds but the strength of the weld.

Panel Contact Resistance Ω JvSL 3 where Jv. In the Calculation of Statically Loaded Weld area of the Calculation tab select the calculation method. There are 3000-6000 spot welds in.

On the ribbon click Environments tab Convert panel Spot Weld Calculator. Resistance spot welding RSW is a major sheet metal joining process in many industries such as the automobile domestic appliances air craft and space craft fabrications. Spot Welding Parameters Basic Calculation 𝐸 0241𝑃𝑡w.

Number of welds - s. Power W tw. Protect yourself and others from flying sparks and hot metal.

Surface contact mm2 L. It is an efficient joining process widely used for the fabrication of sheet metal assemblies. Ad Quality Spot Welding Machine with Competitive Price.

Total plate thickness combination mm 2 Jvπ 4 L 4 where d. Electrodes delivered by the spot welder producer have the working end diameter 7 mm. Energy J Calculation for AC spot welding P.

Spot Welding Parameters Basic Calculation 0241 w 1 where E. Spot welder implemented on the basis of the capacitor principle without a trans-former. Click OK to insert weld calculation.

Then the calculated electrode working end diameter at the thinner sheet is 35 mm for sheets 1 3 mm and 156 mm for sheets 1 45 mm. Trusted China Suppliers Verified by SGS. Comparative stresses approaches a different way to calculate stresses caused by the axial force or bending moment that actuate in the plane perpendicular to the weld plane.

Click Calculate to calculate the joint. The depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the sheet metal thickness. Welding Current A R.

Ad Quality Spot Welding Machine with Competitive Price.

Spot Welding Formula Welding Construction

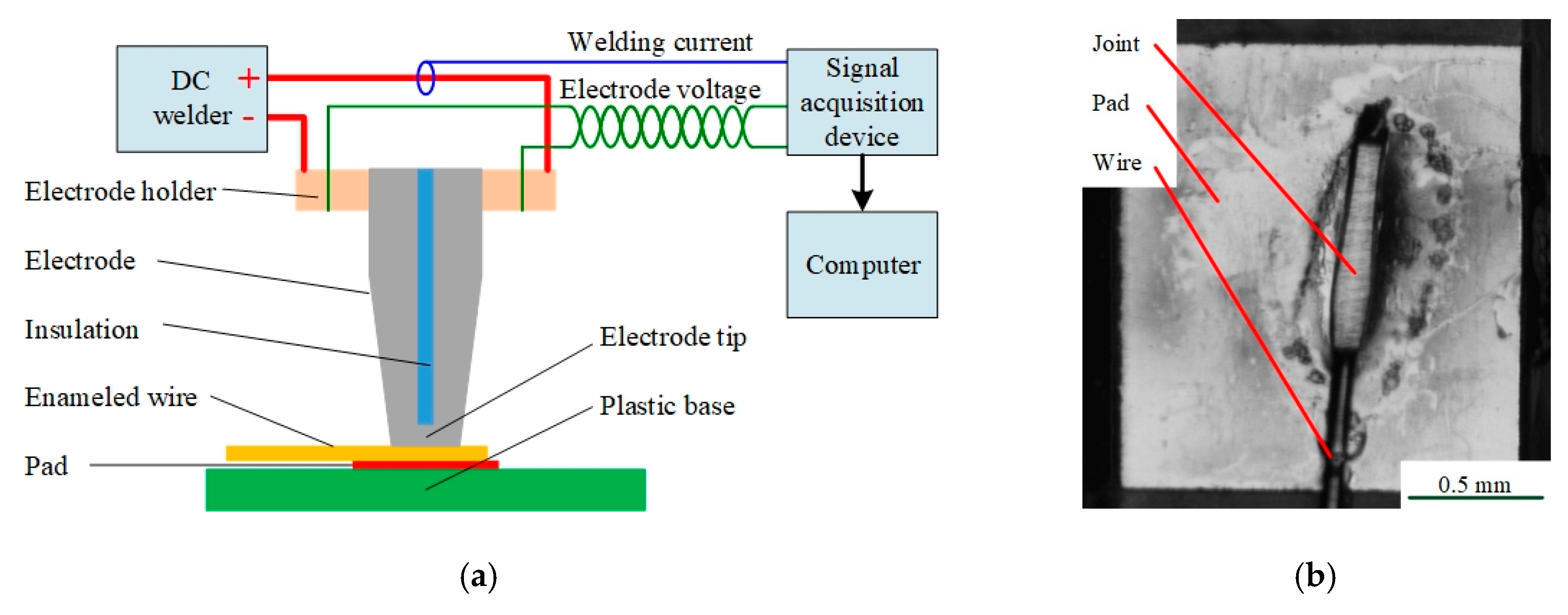

Applied Sciences Free Full Text Quality Monitoring For Micro Resistance Spot Welding With Class Imbalanced Data Based On Anomaly Detection Html

Schematic Representation Of Resistance Spot Welding 1 Download Scientific Diagram

Metals Free Full Text Optimization Of The Resistance Spot Welding Process Of 22mnb5 Galvannealed Steel Using Response Surface Methodology And Global Criterion Method Based On Principal Components Analysis Html

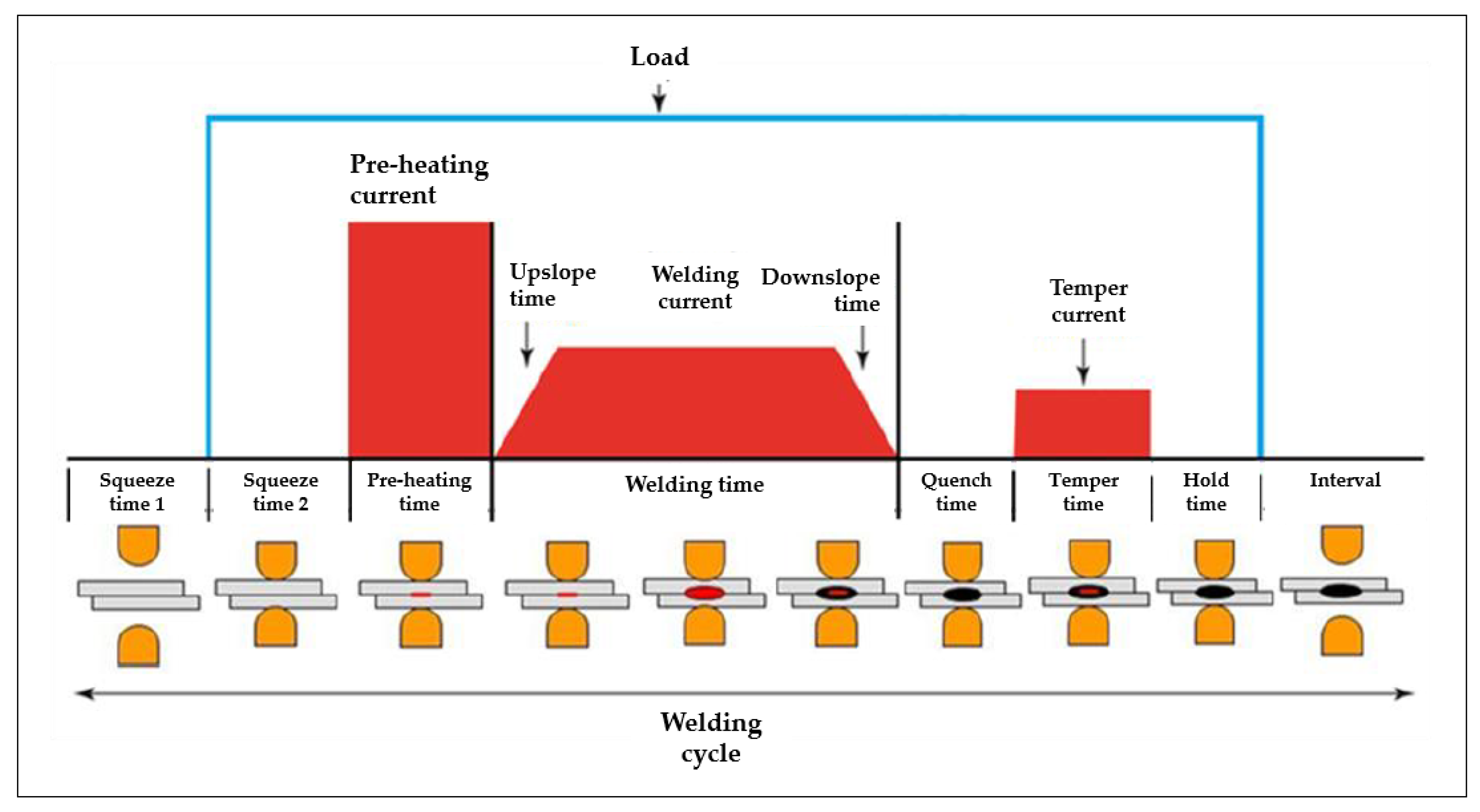

Resistance Spot Welding Cycle F Is The Forging Force And I Is The Download Scientific Diagram

Characteristics Of Shunting Effect In Resistance Spot Welding In Mild Steel Based On Electrode Displacement Sciencedirect

Spot Welding Basic Parameters Setting Basic Calculations Equatio

Spot Welding Formula Welding Construction

Schematic Figure Of Resistance Spot Welding Process Download Scientific Diagram

0 comments:

Post a Comment