It is an alloy of silicon carbon and Ferrum iron. So cast iron has been used in lots of complicated sensitive and highly engineered applications.

Welding Steel Vs Iron Industry Today

Arc Welding is widely used for Welding-cast-iron.

Welding cast iron uses. So what do we do. The mix of nickel and iron has a lower coefficient of thermal expansion which lowers welding stresses and makes it less prone to cracking. Brazing isnt really welding as it doesnt fuse the metal as a weld does.

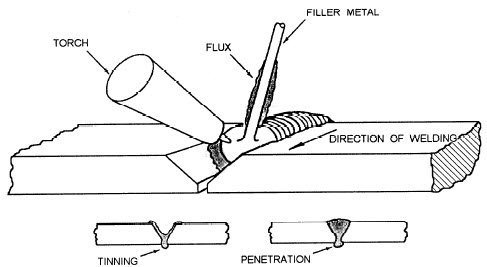

Cast iron cast belongs to a family of carbon alloys with around 24 to 45 of carbon content. Cast iron electrodes and copper zinc electrodes are both suitable for oxy acetylene welding of cast iron. MMA widely used in the fabrication and repair of cast iron because the intense high temperature arc enables higher welding speeds and lower preheat levels.

Nickel electrodes can be used without a preheat. Oxy-acetylene welding is another option frequently used to weld cast iron. Cast iron is difficult but not impossible to weld.

Welding cast iron with flux core Flux-cored welding has many of the best MIG welding characteristics because it uses constantly fed wire. To weld cast iron start by preheating the section youll be working to a temperature between 500 to 1200 degrees F so that its stable enough to work with. Cast iron is difficult but not impossible to weld.

It is thus easy to mechanize and also can be used with flux to adjust the composition of welded metal and the solidifying rate. But it is not done properly the material may get damaged or cracked. Stick welding is a complex welding method.

Because unappropriated steps can give it more cracks in the pieces. In most cases welding on cast iron involves repairs to castings not joining casting to other members. Preheat pieces to at least 250F prior to welds with cast iron or copper electrodes.

At this temperature the iron inside the metal gets stretched preventing it from cracking. The disadvantage of MMA is the greater weld pool penetration and parent metal dilution but using electrode negative polarity. Generally preheated welding is performed by heating the cast iron from 500 to 1200 degrees.

Correspondingly which welding is used for cast iron. Also it doesnt get stretch or deform when it is heated or stressed. For cast iron welding its recommended to use nickel alloy electrodes.

Also Know can you stick weld cast iron. But this is not the end of the journey of cast iron. But its advantage is that it provides the cast iron its hardness.

One is called preheated welding and the other is called non-preheated welding. Stick welding uses different types of electrodes depending on the application color match and amount of machining required after welding. Then fix any cracks or rips in the surface by using a small piece of iron as a repair patch.

One commonly uses nickel based nickel-copper Monel or other bronze electrodes. As one of the most popular metal cast iron got a huge platform in the metal industry. It is an arc welding process where a solid wire electrode is used through a welding gun.

The repairs may be made in the foundry where the castings are produced or may be made to repair casting defects that are discovered after the part is. So its important to understand the reality and the difficulty to adopt stick welding to weld cast iron. Oxy acetylene welding also makes use of electrodes but instead of an arc generated by current an oxy acetylene torch provides the energy for welding.

The hardness of carbon makes it one of the most used materials in the construction business. To weld cast iron stick welding is the preferred method and you dont need any Oxy acetylene torch for it. The main challenge of welding cast iron is its high carbon content in it.

It can be a good solution to repair cast irons. This is the most effective and frequently used technique. It can break and crack as well.

This welding process can join two separate. As a result it produces a stronger and more durable weld. MIG welding is a popular welding process as a beginner.

The most popular manual process employed is probably Shielded Metal Arc Welding SMAW with proper procedures involving preheat and postheat. Its a good option to minimize the extreme heating and cooling of the electric welding processes and its easier to maintain the temperatures of the components with it.

77 Non Cracking Cast Iron Welding Rod

Can You Weld Cast Iron With A Wire Feed Welder Let S Find Out

How To Weld Cast Iron Metal Casting Blog

1kg Cast Iron Welding Electrode Rods Welding Rods Aliexpress

Stick Welding Cast Iron Repair Using 7018 Welding Rods Youtube

Model T Ford Forum Cast Iron Oxy Acet Welding

What Welding Rod To Use For Cast Iron Guidelines For Welding Cast Iron

Stick Welding Cast Iron Repair With Muggy Weld Youtube

0 comments:

Post a Comment