Five Chromium half Molybdenum or nine Chromium one Molybdenum two Group Numbers 5C. The usability determines the ability of a welder to deposit a sound weld metal with a certain filler metal.

Asme Weld Number Tables P Number Base F Number Filler

Wiswesser Welder Training and Testing Institute.

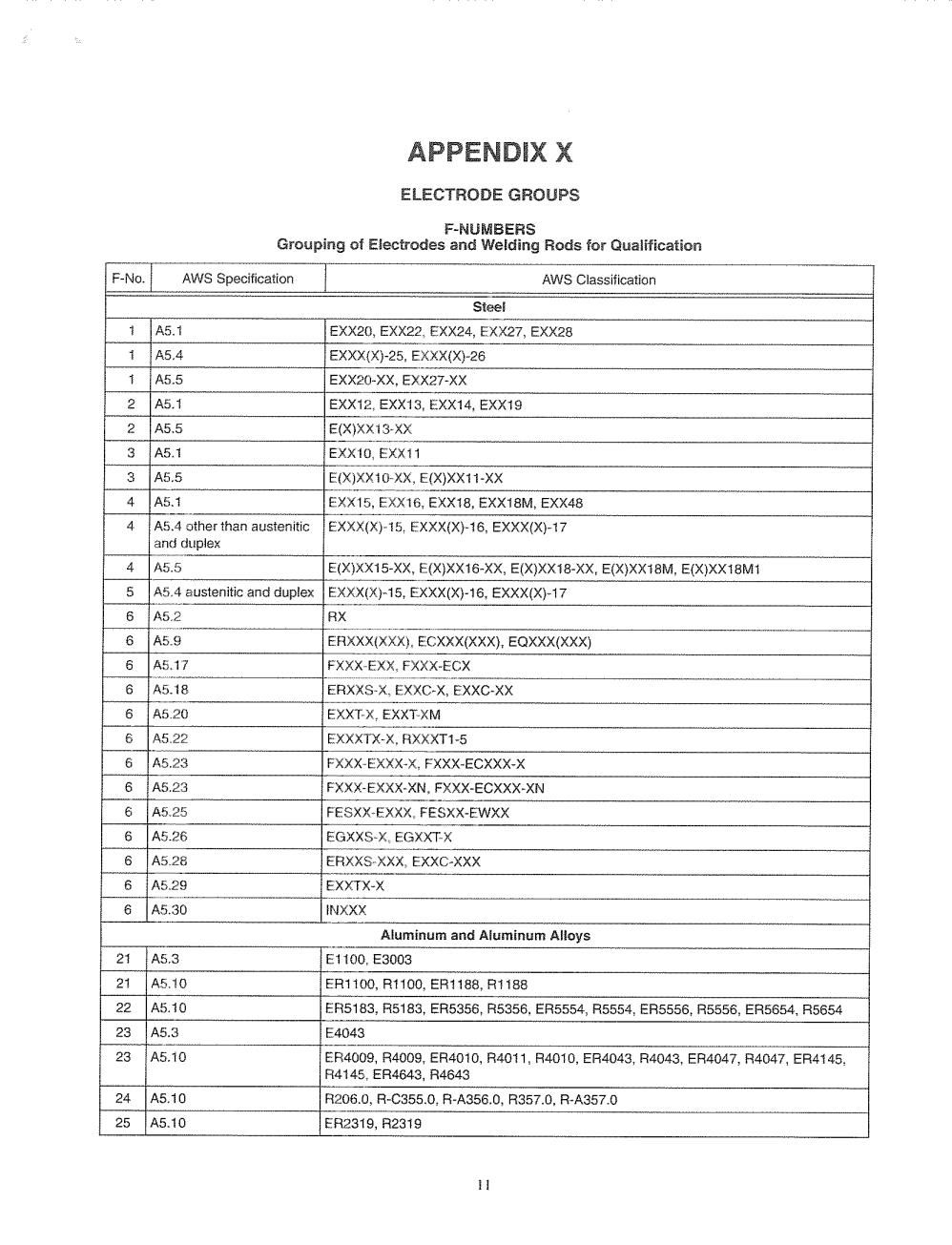

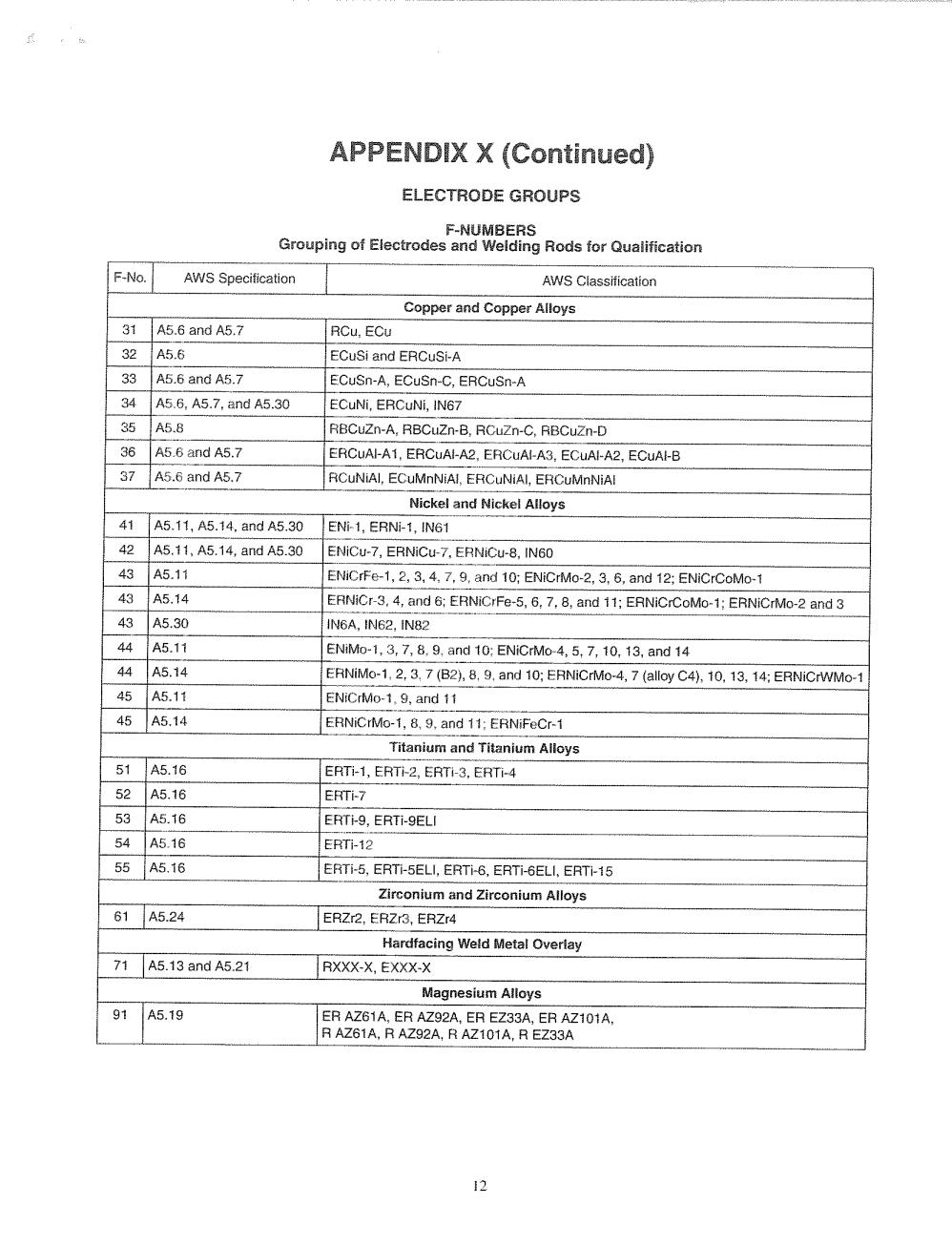

Welding f groups. F number grouping for filler metals is done to reduce the number of welding procedure specifications WPS and welder performance qualifications. Ruof Bechtel Plant Machinery Incorporated J. The following FNumber grouping of electrodes and welding rods in Table QW-432 is based essentially on their usability characteristics which fundamentally determine the ability of welders to make satisfactory welds with a given filler metal.

Thomas Rocky Mountain Testing LLC G. As mentioned by several of our community F1 through F4 are SMAW covered electrodes used on carbon and high strength low alloy steels. The F number grouping of filler metals refers to their similarity on their usability characteristics.

EN ISO 15614-1 may approve the steels in the same sub-group or all the lower sub groups in the main. Ruof Bechtel Plant Machinery Incorporated J. Flat Weld flat joint at 45 degrees 1F.

This grouping is made to reduce the number of welding procedure and performance qualifications where this can logically be done. Titanium and Titanium Alloys. Martensitic Stainless Steels Grade 410 415 429 six Group Numbers 7.

Welding Filler Metal Classifications ASME IX F-numbers A-numbers. The F-number grouping of electrode and welding rod in QW-432 is based essentially on their usability characteristics which fundamentally determine the ability of welders to make satisfactory welds with a given filler metal. Ad Find China Manufacturers Of Welding Electrode Holder.

Pike NASA Langley Research Center W. Stone URS Flint M. 41 through F - No.

The F Number. Nickel and Nickel Alloys. Wisbrock Lockheed Martin Missiles and Fire Control Retired R.

21 through F - No. 51 through F - No. Ferritic Stainless Steels Grade 409 430 8.

The usability characteristics fundamentally determine the ability of a welder to produce sound welds with a given filler metal. North Americas Largest Fleet of Welding and Positioning Equipment WELDING ELECTRODE CLASSIFICATIONS MILD STEEL COATED ELECTRODES E7018-X E Indicates that this is an electrode 70 Indicates how strong this electrode is when welded. Depending on the code D11 for example if a welder qualifies using an electrode from an F4 group they are also qualified to weld with electrodes from groups F1 through F3 as well but if a welder qualifies to a F1 group they are not qualified to use groups above F1 unless they perform a seperate qualfication.

Chromium Molybdenum Vanadium five Group Numbers 6. 1 through F - No. F-Numbers to filler materials.

31 through F - No. Based on Alloy content for materials in all the other groups. Steel and Steel Alloys.

F numbers are a means of grouping filler metals. Pike NASA Langley Research Center W. Austenitic Stainless Steels Group 1 - Grades 304 316 317 347.

The Group number in welding assigned additionally to the P number materials. Drag a column header here and drop it to group by that column. Aluminum and aluminum - base alloys.

Ad Find China Manufacturers Of Welding Electrode Holder. Groups are not considered for material grouping in EN ISO 15614-1 the grouping is based on same specified yield strength or less in the main group the same as EN288-3. The F5 group are SMAW covered electrodes used for joining stainless steels.

In the beginning when SMAW was King of the Mountain the F numbers had more validity. This article provides information about Group number in welding procedure specification based on the requirement of ASME Code Section IX. Sekely Welding Services Incorporated M.

Stone Canadian Welding Bureau G. Wiswesser Welder Training Testing Institute Advisors to the AWS B2 Committee on Procedure and Performance Qualification. Sekely Welding Services Incorporated M.

Copper and Copper Alloys. These group numbers divide a P number to several group numbers for the purpose of welding procedure qualification when impact testing. The basis for F number grouping is usability characteristics.

This grouping is made to reduce the number of welding procedure and performance qualifications where this can. F Number grouping of electrodes and welding rods in Table QW-432 is based essentially on their usability characteristics which fundamentally determine the ability of welders to make satisfactory welds with a given filler metal. ASME F Number.

P Number F Number And A Number In Welding Asme Section Ix Welding Ndt

Pin By Henk On Welding Welding Rod Chart Welding Rods Arc Welding

Whatsapp Group Invite Welding Torch Welding Logo Welding

P Number F Number And A Number In Welding Asme Section Ix Welding Ndt

Millerwelders A Close Up Of An Aluminum Weld Produced By Using A Complete Aluminum Welding Package Http Weldingproductivity Com Article Addressing Aluminum

P Number F Number And A Number In Welding Asme Section Ix Welding Ndt

0 comments:

Post a Comment