Here we discover the different types of welding joints and the types of welding styles used to create each. Welding is a fabrication process whereby two or more parts are fused together by means of heat pressure or both forming a join as the parts cool.

How To Solder Soldering Is Defined As The Joining Of Metals By A Fusion Of Alloys Which Have Relatively Low Melting Points In Other Words You Use A Ppt Download

Welded iron or steel angles shapes and sections for railways eurlex eurlex.

Welding iron definition. Upon cooling the structural steel parent metal and weld or filler metal will act as one continuous part. Jul 14 2015. Basically the welding of cast iron is the brazing operation.

From the aeronautic industry to automotive and residential its applications and critical roll cannot be understated. Welding technique used for joining metallic parts usually through the application of heat. In welding processes the electron emission is either of the thermionic type for example in gas tungsten arc welding plasma arc welding and carbon arc welding or it is of auto-emission type in conjunction with auxiliary means of ionising the air gap between the electrode and the work-piece such as for shielded metal arc welding submerged arc welding and gas metal arc welding.

Welding characteristics iron powder added to electrode coating also favourably affects the weld metal quality. Welding Technique The details of a welding procedure that are controlled by. Automatic Welding is a weld made by equipment such as robots.

Towards gas and arc welding techniques when these were developed to useful production and repair methods through the 1930es. You should not attempt it on the strength of reading a brief Internet article no matter how. This technique was discovered during efforts to manipulate iron into useful shapes.

Welding Rod A form of welding filler metal normally packaged in straight lengths that does not conduct the welding current. The process involves joining two pieces of metal under extreme heat and pressure. The applications of welding are limitless.

6000 9 Basic of Welding Structural welding is a process whereby the parts to be connected are heated and fused with a molten filler metal. 6010 welding rods can be used for open butt welding but 7018 cannot and requires a backing strip to provide a surface for the electrode to weld. Simultaneous melting of the flux coating on the rod will form gas and slag which protects the weld pool from the surrounding atmosphere.

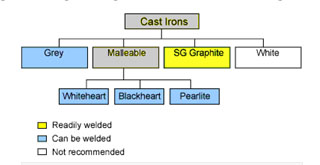

Welding joints are strong as compared to the soldering. The ductile cast irons and others are brazed using the cast iron brazing process. Weld iron Definition in the dictionary English.

Welded blades were developed in the 1st millennium ce the most famous being those produced by Arab armourers at Damascus Syria. The American Welding Societys AWS definition of a joint is the manner in which materials fit together. Welding Symbol A graphical representation of a weld.

Also known as manual metal arc welding MMA or MMAW flux shielded arc welding or stick welding is a process where the arc is struck between the metal rod electrode flux coated and the work piece both the rod and work piece surface melt to form a weld pool. Soldering brazing and welding are all methods of joining two or more pieces of metal and selected other materials. In the soldering process the workpiece or base metal is heated.

A main objective became to develop and maintain a range of welding equipment that is suitable for onboard welding backed by. Daves Architectural Iron Works specializes in stud welding. Stitch or Skip Weld BMA Engineering Inc.

The joints made in the soldering process are weaker compared to the welding. The cooling effect of the additional iron allows quicker solidification of the weld metal. The completed welded joint may be.

In welding process base metal as well as fillers are melted. Welding cast iron is a precision task that requires high heat and often expensive equipment. Match all exact any words.

Experts believe that in one way or another welding. They are also methods used to fill gaps in metal parts. A welded part includes two metal structures forced to form a robust bond at the joints.

Backup Strip is a strip or section of steel butted up to an open gap between two pieces of steel. It has a filler rod made of nickel. Welding is usually used on metals and thermoplastics but can also be used on wood.

Imposing a provisional anti-dumping duty on certain welded iron or steel tubes originating in Romania EurLex-2 EurLex-2.

Soldering 72 The Fundamentals Flite Test

A Z Of Welding Terms Welding Glossary Westermans Blog

How To Weld Cast Iron Metal Casting Blog

Welding Definition Their Types And Process Australian General Engineering Vietnam Metal Fabrication Vietnam

Soldering Iron Vs Soldering Gun

Cast Iron Welding Basic Procedures Weld Guru

4 Popular Types Of Welding Procedures

Soldering Iron An Overview Sciencedirect Topics

0 comments:

Post a Comment