The inductive reactances and resistances of the windings in such a welding. These two winding have no electrical connections but magnetically they are coupled together.

Find Arc Welding Machine Stock Images In Hd And Millions Of Other Royalty Free Stock Photos Il In 2020 Arc Welding Machine Welding Machine Electronic Circuit Projects

Uction of the welding machine.

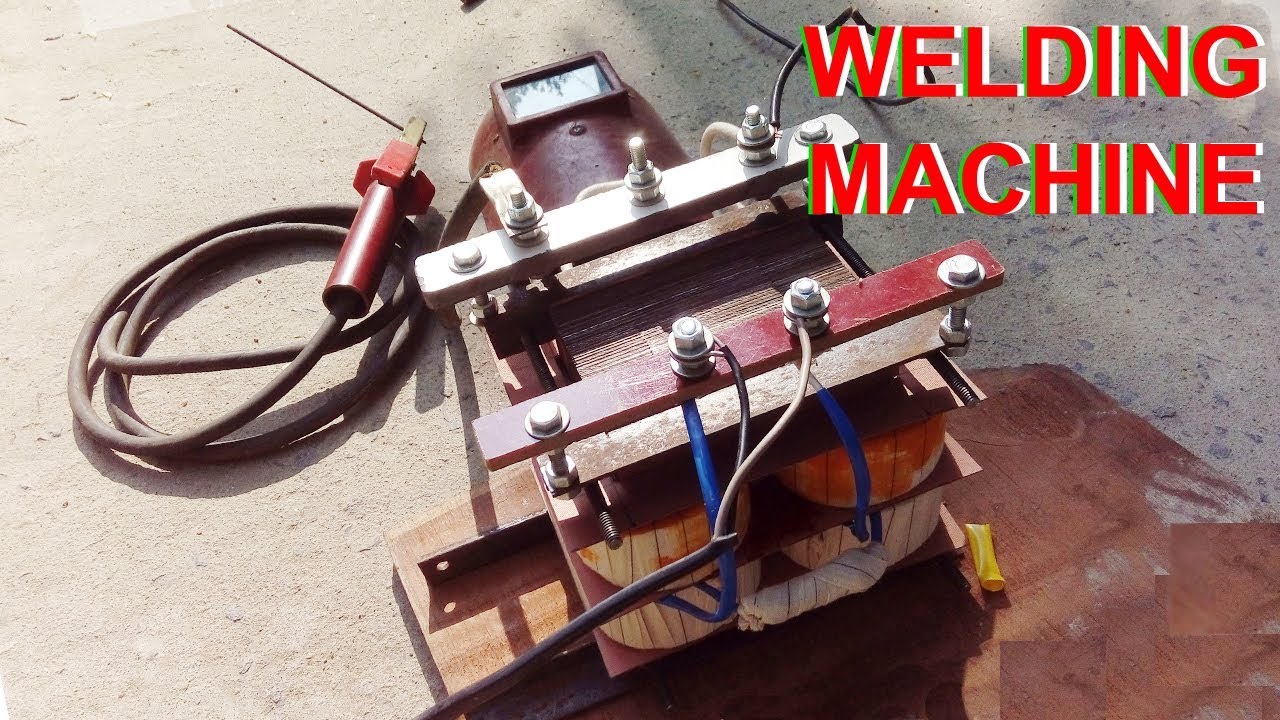

Welding transformer construction. The transformer is single phase which. In this case 80 weight of the machine is transformer so size is larger. It can simply be defined as the process of joining two or more pieces of metal to make the act as a single piece.

EER42X15 welding transformerWelcome custom-design transformers22422320410494654044592249384. Construction of welding transformer. In all the above welding machines incoming voltage is reduced by using transformer and is used for welding directly or using rectifiers.

You see that it is essentially a shell type of core. Usually between 15 and 45 volts. The welding current at the full-wave rectifier output is normally controlled.

The main function of transformer is to change high voltages low amperage ac power for welding. Inversion DC Argon Arc inverter welding transformer mosfet series Detailed Product Description1advanced inverter technology 2small volumnlight weight 3safe and reliable 4suit for wire filling welding Performance characteristics. It consists of transformer core primary and secondary windings.

This is often done by melting the work pieces and adding a filler material to form a pool of molten material that cools to become a strong joint. Construction Lamination Transformer Former Copper Coil Insulating Materials Methodology Casing Coupling and Electrical Holder. The windings are on separate bobbins with the primary on the right and the secondary on the left.

The secondary current is quit high and it may be typically 200A to 600A but it could be much higher. Welding transformers are designed upon the nature of welding operations. In a welding transformer construction as set out in claim 1 means co-operating with the movable shunt core section and the margins of said gap guiding the section for sliding through the gap comprising a pair of plates on the outer sides of said shunt core section overlapping the margins of said gap.

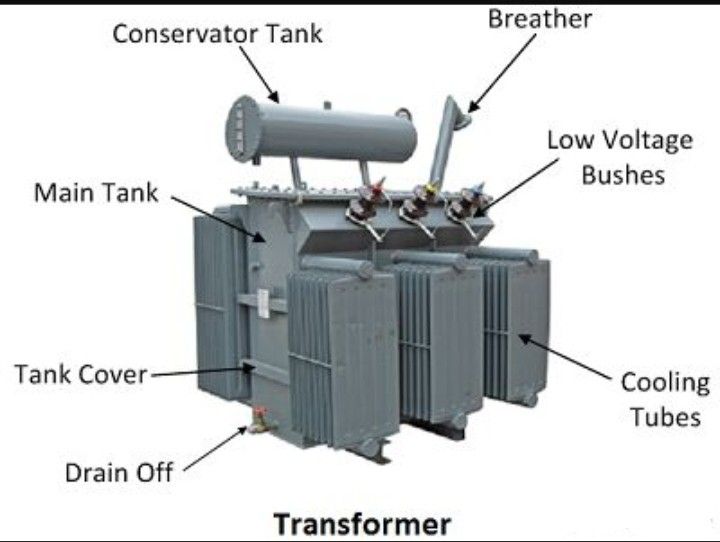

Construction of Transformer. The construction and working principle of the transformer is very simple for the small-sized transformer. In the invertor type machines the incoming voltage is rectified AC to DC and filtered.

It consists of an input converter welding transformer and a full-wave rectifier mounted at the transformer secondary. This type of welding transformer consists of a normal reactance single phase step down transformer and a separate reactor or choke. A multi-arc or multi-operator welding transformer system utilises a high current constant voltage power source for providing a number of welding circuits at the same time.

For an inverter-type welding machine the transformer is designed to be small in size and less weight compared to conventional welding machine. This photograph shows the construction of the transformer used in a small 150 ampere inexpensive electric arc welding unit. This discharge is known as an arc.

It has a magnetic core with primary winding which is thin and has large number of turns on one arm. Fabrication by welding has replaced many of large application for casting where it provides stronger sounder lighter structure less susceptible to damage by chockModern welding began just before the end of the last century 18 th Century with the development of method of. The welding transformer reduces the voltage from the source voltage to a lower voltage that is suitable for welding.

Has shell type of lamination core and insulated. This paper focuses on the. For a high range of power transformer the core and windings are placed in a transformer tank with additional accessories.

Chapter Three of Design And Construction Of An Arc Welding Machine Contains. 1 housing 2 cover the vent Windows 3 housing cover 4 handle 5 socket 6 plug 7 terminal 8 bolt for grounding connection Fig. Chapter three of this Design And Construction Of An Arc Welding Machine academic work is available order and download full work.

The input voltage to transformer may be 440 V or 220 V. A welding transformer has two circuits one is primary and other is secondary circuit. Welding transformer is a step down transformer.

Such a system is used when there is a large concentration of welding points in a relatively small operating area for example in ship-building construction sites for power stations refineries and chemical plants. In an arc welding machine electric discharge is used for welding. A secondary winding with less number of turns and high cross-sectional area on the other arm.

High Reactance Welding Transformer With Movable Magnetic Shunt Welding Transformers Simple Electronics

Welding Transformer Working Principle And Applications Electrical Edition Electrical Installation Welding Transformers

Build A Transformer Or Constructing Transformer Electronic Circuit Projects Electronic Schematics Transformers

Welder Current Limiter By Mike Worth Homemade Welder Current Limiter Constructed From A Surplus Microwave Oven Transform Welders Welding Projects Diy Welder

Construction Of Transformer Transformers Step Down Transformer Current Transformer

Transformer Inner View Electrical Engineering Books Electrical Engineering Books Electrical Engineering Transformers

How To Make 12 Volt 30 Amp Battery Charger Transformer Winding Easy At Home Yt 48 Youtube Welding Machine Welding Welding Table

Mot Welder On 120vac Youtube Welders Home Electrical Wiring Diy Welding

0 comments:

Post a Comment