When using welding machines or portable generators be sure that they are properly grounded before you start the machine. It is preferable to connect the work lead directly to the work.

How To Ground Your Welder A Helpful Guide Welders Lab

The equipment passport as a rule does not contain such recommendations.

How to properly ground a welding machine. Before doing the set of MIG welder machine an individual requires to check a few things which are the following. Which reminds me I have two brand new rods laying next to my two. Youve got more than a few problems including arcing and sparking to that common earth ground where everybody is.

Varieties of welding machine. It is necessary to decide on the type of welder. GroundedConnected to earth or to some conducting body that serves in place of the earth.

The welding machine instruction manual includes specific instructions on how to ground the welding circuit and components in the surrounding area to minimize the radiation effect. Welding Jacket mask and the welding. Grounding is accomplished through the permanently attached power connection supplying the machine the plug or by a separate clamp and wire connecting the case or frame of the machine to ground like the building.

In general as the included angle increases the weld penetration increases and the width of the weld. Unless a separate grounding conductor is used to connect the workpiece to an earth ground the work lead will not be grounded. The Welder Check to make sure that the valve to the shielding gas is open and that you have around 20ft 3hr flowing through the regulator.

For the latter the end is typically ground to a specific included angle often with a truncated end. In some cases the user might encounter small electrical shocks while touching the welder it might not be constantly but this can be dangerousThis problem occurs if the frame of the welding machine is not grounded properly. Apply your ground clamp close to the weld point so the current flow only occurs through a short distance the arc a little of the parent metal and back to the welding leads both for safety AND for better performance.

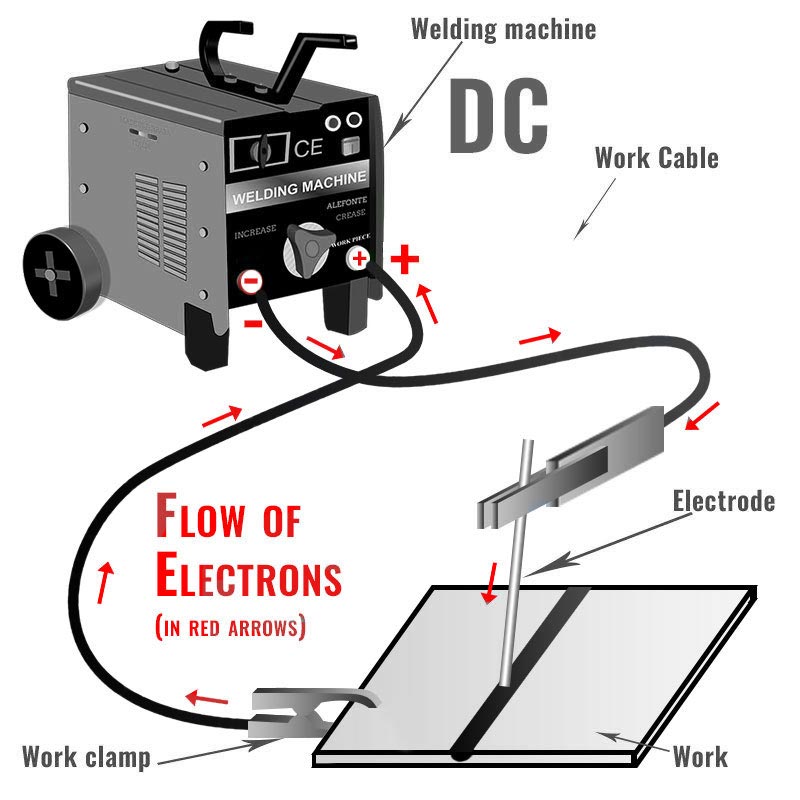

Ground ConnectionAn electrical connection of the welding machine frame to the earth for safety. One way to minimize high-frequency signal radiation is to ground the welding circuit. Before you start welding make sure things are properly setup at both the welder and on the piece you are about to weld.

Tween the source of arc welding current and the work. The ground wire can also be attached from the machine to the main steel structure of a. If a machine is not grounded correctly the electrical current will use the welder as a human ground.

When grounding a welding machine check the individual specifications for your machine. The welder needs to be on the grounding clamp attached to your welding table or to the piece of metal directly and you need. In the refinery i work in all engine welders have to be grounded from the machine frame to a pipe rack or earth groundBob They inspectors used to do that here unsure if they still do it though say if a machine were to have a generator problem and short its arc to frame ground.

The work lead should not be referred to as the ground lead. If you are outside the process of grounding may be a. The way equipment is grounded has nothing to do with the or - stud on the front of the welding machine.

NATURE OF THE HAZARD Some basics. Portable and Vehicle-mounted Welding Generator Grounding. Attaching the welding clamp flush to the underside of a workbench will keep it from getting in the way during a weld.

Bottle of the gas regulator and shielding gas availability. Grounding the machine itself is accomplished through the permanently attached power connection that supplies your machine or by using the separate clamp and wire connecting the case or frame of your machine to the ground. Grounding the welding material Once the welder is ready to begin the welding process they will attach a ground clamp to the metal workpiece.

It is necessary to connect correctly so that during operation you do not damage the electrical wiring sockets and the device itself. The purpose of grounding a welder is to provide a location for the electricity to discharge to the ground. Grounded effectivelyIntentionally connected to earth through a ground connection of sufficiently low resistance and with adequate current-carrying.

What you want is to have that welding current limited to JUST the area in which you weld. A rod approximately 8 foot in length is driven into the ground through a hole in the concrete. If this occurs serious injury or death is possible.

Electrical shocks while touching the welder. Grounding involves running a ground wire from the machine to an appropriate grounded source such as a grounding rod driven several feet into the ground. For this problem one must read the user manual properly and learn the grounding procedure of the.

Grounding to earth is used to protect the machine from lighting strikes and other stray voltages. This attaches directly to the welding machine. A grounding weld can be attached at two placeseither the metal welding workbench itself or the work that is being welded on.

Electrodes are usually used. Various electrode tip geometries affect the weld bead shape and size. Then a wire maybe 8 gauge is connected between the machine and the grounding rod.

Ensure the proper availability of the power source. This is essential because it helps complete the electrical circuit that will create the arc which is used to join the two pieces of metal together. This is the basic method for grounding a welding table.

Connecting the welding machine can be a problem for those who purchased such a tool for the first time or asked a neighbor. Ground Clamp is required.

How To Ground Your Welder A Helpful Guide Welders Lab

How To Hook Up Stick Welding Leads Welding Tribe

How To Hook Up Stick Welding Leads Welding Tribe

How To Ground Your Welder A Helpful Guide Welders Lab

Grounding And Arc Welding Safety

Grounding And Arc Welding Safety

Welding Machine Troubleshooting Tips

0 comments:

Post a Comment