Features of the Lincoln 140 HD. Monitor the temperature of your base metal and weld metal as failure to do so may give rise to avoidable performance problems in the long run.

Carbon Arc Welding Png Images Pngwing

Pulsed MIG has good control and with the proper settings together with a well-trained welder the job could have a near flawless result.

How to welding stainless steel with lincoln 140. 308L is also an acceptable choice. Welding stainless with a handler 140. The Lincoln Electric Weld 140 HD has a tapped control that can be considered as a downside if you are looking for more control over the welder settings but for beginner welders it makes life much easier by not over complicating things.

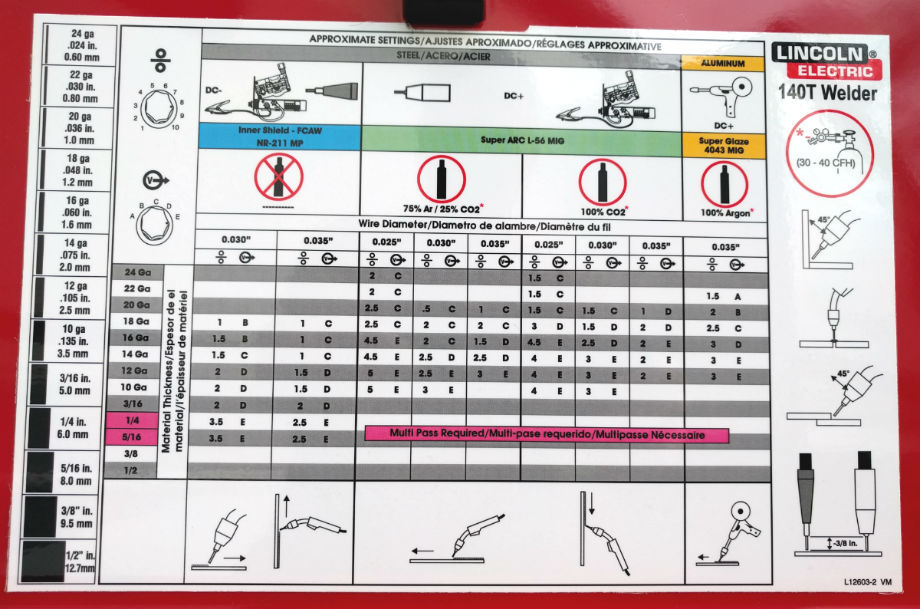

When welding stainless steel one of the things you need to focus on is temperature. Itll also weld type 430 stainless steels. You set your welding output voltage on your Lincoln 140 using one of the dials on the front of your welder.

You also need to learn how to do it. The chromium content may be increased and other alloying elements added or adjusted to meet specific end-. General Usage Rules for Lincoln Mig Welders.

But iam doubleing the wire speed to keep it from burning through. It is highly important to clean the metal before any type of welding and cleaning helps get rid of all the dust and other particles before welding stainless steel. Iam using 030 wire and and the lowest setting for the wire.

Type 308L flux core stainless steel wire will weld 300 series stainless steels. Trusted China Suppliers Verified by SGS. Lincoln Weld Pak 140 Front Dials.

Put On Your Safety Gears. The dial on your Lincoln is a tapped dial. To weld the ferritic stainless steels filler metals should be used which match or exceed the Cr level of the base alloy.

Lincoln 140C this welder is capable of welding various kinds of metal including Aluminum Steel Mild Steel Stainless Steel etc. Stainless Steel Welding Characteristics By definition stainless steels are iron-base alloys containing 10 or more chromium which imparts to the metal the corrosion-resistant properties for which stainless steels are so highly regarded. Trusted China Suppliers Verified by SGS.

Iam using the tri-mix gas and i. Salt lakeCity UT I am welding 20guage stainless duct with a handler 140 my welds are coming out black. Right up to type 308.

Non-standard ferritic stainless steels. Ad China Sale Welding Machine. They are characterized by weld and HAZ grain growth which can result in low toughness of welds.

Without any conflict Power MIG 140C can weld thicker metals. MIG welding with your Lincoln mig welder. And one thing to remember is that you should refrain from using the same brush that is used for cleaning carbon steel because the residue carbon left in the brush can get embedded over the stainless steel and starts rusting it in no time.

Use stainless steel MIG wire. This is the number one most crucial thing every welder must do before beginning to weld. At first you need to put on your welding jacket or at least a full sleeve shirt in.

Please Take Note of this. The Step-By-Step Process to Weld Stainless Steel Both MIG TIG Welding So now that we have all the pieces in place lets combine them and get the actual job done. Here are some factors and best practices to keep in mind when welding stainless steel with a MIG welder.

Ad China Sale Welding Machine. Many welders hate tapped control system but it gets the job done with no problems at all. L means low carbon content 3XXL stainless steel means carbon content 003 while standard 3XX stainless steel can contain up to 008 carbon content.

This is suitable for little workshops like Rental garages Auto body shops or other household projects. Well it can happen when you heat the stainless steel material for too long and at a temperature of 800 1400 degrees Fahrenheit. Type 409 is available as metal cored wire and Type 430 is available in all forms.

How To Weld Stainless Steel With a MIG Welder. Your Lincoln Electric 140 has a welding output of 30 to 140 Amp in four voltage settings. For perfect results you have to use a stainless steel MIG wire.

Type 309L flux core stainless steel wire will also weld all 300 series stainless steels up to type 309. The answer to your first question is yes you can MIG weld thin gauge stainless steel in a short circuit mode with compact type 120V or 230V input power MIG welders see example in Figure 1. Weld decay is where your stainless steel weld cracks and fails over time.

As a rule of thumb it is recommended to use a compact 115volt input MIG wire feederwelder indoors on clean new steel that is 24 to 12 gauge thick. MIG Welding sheet metal efficiently involves obtaining good fusion while simultaneously controlling. Pulse MIG Welding Stainless Steel.

How to Set Your MIG Welder in Joining Stainless Steel Tune your welders polarity. The machine would have the same amperage and resulting material thickness capability with stainless steel as it does with carbon steel. 12 gauge is a little less than 18 thick.

When welding 304 stainless steel use type 308 welding material because the additional elements in 308 stainless steel can better stabilize the weld area. 24 gauge is less than 116 thick. Of course its not enough that you know whether can you MIG weld stainless steel or not.

Your welder should be set to direct current DC positive to create a reaction between your feeder wire and steel surface.

Lincoln Pro Mig 140 Short Demo Setup Youtube

Lincoln Electric Power Mig 140 Mp Multi Process Welder With Tig One Pak K4499 1

Lincoln 140 Mig Welder Reviews The Models Explained Welditu

Mig Welding 1 4 Inch Steel With Lincoln 140 Hd Welder Youtube

Buy Lincoln Electric Pro Mig 180 Welder 230 Volt Mig Flux Cored Wire Feed Model K2481 1 Online In Indonesia B008m8id4w

A Comprehensive Lincoln Pro Mig 140 Review 2021 Pick Welder

Can You Guys Give Me Some Advice On The Lincoln 140hd I Want To Know If It S Worth The Money Or If There S Better Options For Less Out There Welding

Lincoln Pro Mig 140 Welding 1 4 Steel Youtube

0 comments:

Post a Comment