Be sure to connect the power lead to positive polarity and the. If you need to ball your tungsten for aluminum TIG welding you can initiate a quick arc.

Aluminium Welding How To Weld Aluminium Australian General Engineering

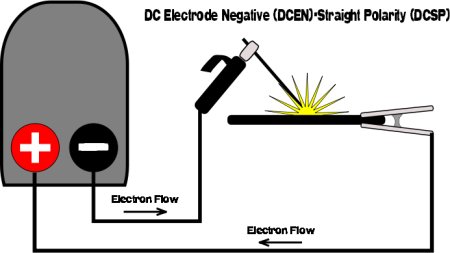

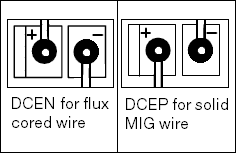

If your machine came set up for FCAW chances are the wires are run with electrode negative.

Polarity for aluminium mig welding. Trusted China Suppliers Verified by SGS. This is a common mistake that many beginning welders make. Argon 5 to 25 CO 2.

Consider material thickness. MIG Welding Aluminum Polarity. To MIG weld aluminum thinner than 14 gauge 074 inch it may be necessary to use specialized pulsed MIG or AC TIG welding equipment.

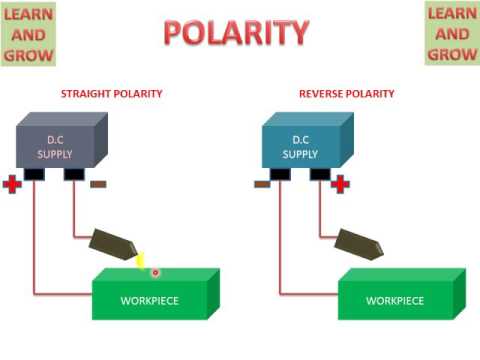

This type of polarity setting is also called reverse polarity and involves electrons going through the ground cable and back to the gun. Polarity for MIG Welding Aluminum. Youll set your welders polarity to DC.

All MIG welding including on aluminum materials requires electrode positive polarity while flux-cored processes typically use electrode negative. However you can use positive polarity to your advantage in one key situation. There is rarely a reason to run positive polarity DCEP for TIG welding.

Its also referred to as reverse polarity DC Electrode Positive or DCEP. The output capacity of your welder determines the thickness you can weld. This setting is the same used for MIG welding with solid steel wire.

That means your MIG gun connected to the positive terminal within your welder. It will burn up the tungsten and ruin your weld. 100 argon gas is usually the gas of choice but mixtures like 5050 argonhelium can be helpful for welding thick sectionsMake sure the polarity is connected properly.

General purpose shielding gases for MIG welding are mixtures of argon oxygen and CO 2 and special gas mixtures may contain helium. So for gasless MIG welding polarity when using flux core wire your MIG welding polarity settings should be set to direct current electrode negative or DCEN. Argon 2 to 5 oxygen.

Material thicknesses of aluminum that can be MIG welded are 14 gauge and heavier. Reverse polarity is used for all MIG welds. What is a Suitable Polarity for MIG Welding.

Finding The Settings For Aluminum Welding On Your MIG. Trusted China Suppliers Verified by SGS. Direct current reverse polarity DCNP is the type of current that is utilized for MIG welding aluminum.

What Polarity Setting is Needed. If you try to GMAW aluminum in electrode-negative polarity youll get a weld with no penetration that just lies on the surface. Ad Quality Mig Welding Machine with Competitive Price.

Welders who are using this welding method prefer using the direct current electrode positive or the direct current electrode negative. The gases which are normally used for the various materials are. MIG welding is the most basic type of welding process which is suitable for starters.

Usually there will be a short lead that can be connected to either a positive or negative terminal. Aluminium copper or nickel alloys. The polarity connections for the torch are commonly found either on the inside of the welder near the wire drive system as shown below or on the front of the welder.

With DCEN the negative terminal inside your machine is hooked up to your electrode your MIG gun while the positive terminal is. The RP electrons impart the majority of the arc energy at the MIG wire tip melting the wire in a consistent manner. Ad Quality Mig Welding Machine with Competitive Price.

With RP the electrons travel from cathode spots on the negative work to the positive anode on the MIG wire tip. Check your MIG welder and ensure your using the right polarity. Make sure the welding machine is set on the right polarity.

Failing to set everything correctly will result in poor welds. Connect this to the Negative -. Aluminum MIG Welding Tip.

Aluminum wire needs your MIG welder set to DCEP direct current your MIG gun electrically positive. The electrode is connected to the positive pole while the work also known as the ground is. When welding Aluminum setting the correct polarity of your MIG welder is very important to a successful weld.

Aluminum welding needs DCEP direct current electrode positive. Another way of saying reverse polarity is Direct current electrode positive or DCEP. You can start with the Miller welding calculator to find aluminum MIG welding settings.

How To Set Polarity. Mig welding aluminum requires reverse polarity. If you are switching your wire feed welder between processes make sure to switch your polarity.

This means your MIG gun spool gun connected to the positive terminal. My advice is to always have your welder set on direct current electrode positive DCEP with aluminum MIG welding. This type of welding method requires the DCEP or the Direct Current Electrode Positive polarity.

Mig Welding Aluminum With A Spool Gun

How To Set Your Mig Welding Polarity Settings Makemoneywelding

The Complete Mig Welding Guide Be A King Of Mig Welding

How To Set Your Mig Welding Polarity Settings Makemoneywelding

Mig Welding Aluminum For Beginners Makemoneywelding

How To Set Your Mig Welding Polarity Settings Makemoneywelding

Polarity Straight And Reverse Youtube

First Time Mig Welding Aluminum With A Spool Gun And I Can T Figure Out What I M Doing Wrong I Have The Argon Set Between 30 40 Cf And The Amps And Feed Set

0 comments:

Post a Comment