This arc melts the base metals. METAL INERT GAS MIG WELDING Metal inert gas welding or gas metal arc welding GMAW is a group of arc welding process in which the workpieces are joined by the heat obtained from an electric arc struck between a bare uncoated consumable electrode and the workpiece in the presence of an inert gas atmosphere.

Difference Between Mig And Tig Welding The Welding Master

The process is semi-automatic because an electrode wire and gas are automatically fed through the gun at a user defined speed or pressure when the operator pulls down the trigger the electronic arc can also be user defined and carried out automatically on operation.

Principle of metal inert gas welding. At this point the welding gun is carrying current. The two base materials are melted together forming a join. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

The gun feeds a shielding gas alongside the electrode helping protect the weld pool from airborne contaminants. Whenever it is placed closed to the workpiece an arc is produced. It uses a fresh metal electrode that is protected by gas like helium argon etc.

This welding is same as TiG welding except a non-consumable electrode replaced by consumable electrode wire. This process is also termed as gas metal arc welding GMAW. This gas shield is around the arc and the weld pool helping to protect the weld from the external atmospheres.

In this type of arc welding process a filler wire can be fed constantly using a non-consumable metal electrode for welding the metal. Gas welding process is quite simpler compare to arc welding. Gas metal arc welding GMAW is a high-speed economical process that is sometimes referred to as metal inert gas MIG welding.

Today we will learn about What is MIG welding principle working equipments applications advantages and disadvantages. This process is also known as gas tungsten arc welding. It is also referred to as MAG welding Manual Metal Arc Welding.

At some places peoples use wire welding as a slang name for it. This process is automated or semi-automated arc welding process in which inert gases are used as shielding gas and a consumable wire electrode is. Now the regulate pressure of gas and oxygen supplied to the torch where they properly mixed.

MIG welding or Metal Inert Gas welding is an arc welding process that uses a continuous solid wire electrode and shielding gas for laying welds. GMAW Gas Metal Arc Welding is another name of MIG welding. MIG welding is one of the more simple welding methods of metal welding as it does not require a high level of skill to achieve results.

Gas metal arc welding GMAW is also called Metal inert gas welding MIGW. That type of arc welding which uses a consumbale metal electrode in an inert gas atmosphere to produce a weld is known as MIG metal inert gas welding. Shielding gas protects the weld from atmospheric contamination.

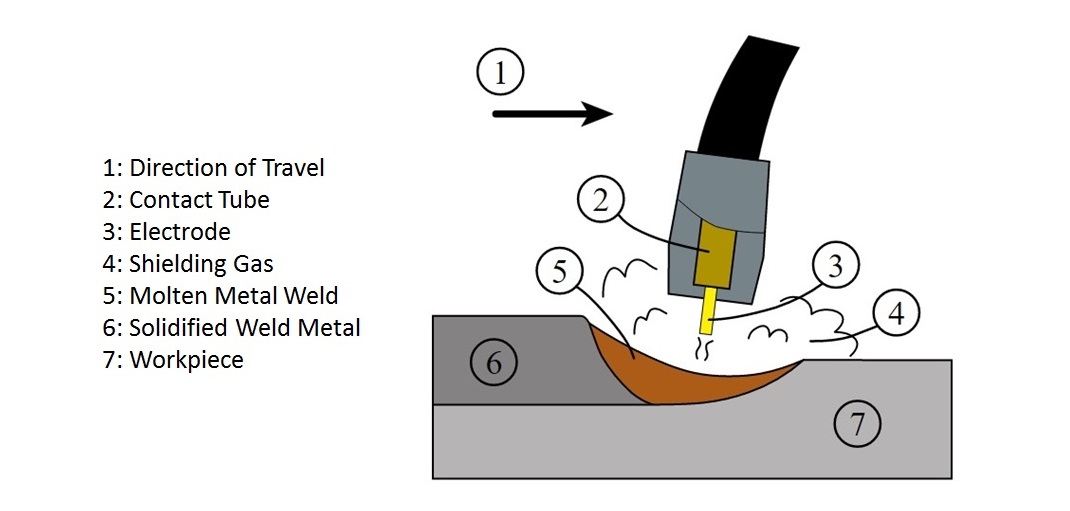

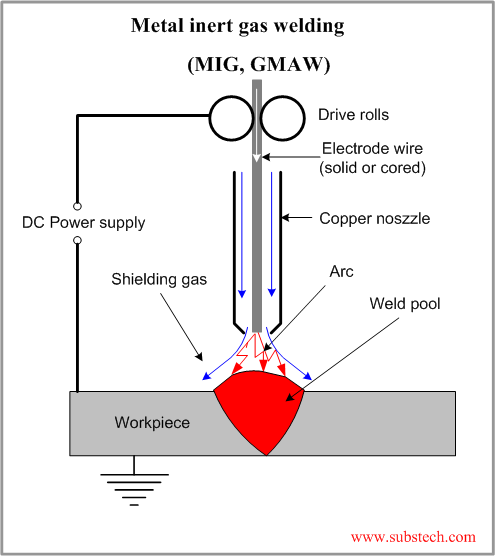

The gas cylinder and oxygen cylinder connected to the welding torch through pressure regulators. The basic principle of MIG Welding is an arc is maintained between the end of the bare wire electrode and the work piece where the heat source required to melt. Illustrates the working principle of a MIG welding whileThe schematic arrangement of MIG welding equipment The arc is struck between the metal electrode and the workpiece The electrode is in the form of a.

Metal Inert Gas MIG welding is an arc welding process that uses a continuous solid wire electrode heated and fed into the weld pool from a welding gun. In this process all the equipment are connected carefully. Inert gas supply is provided around the electrode during the process.

PRINCIPLE OF MIG WELDING Gas Metal Arc Welding GMAW is commonly referred to as MIG welding Metal Inert Gas welding. MIG stands for metal inert gas welding or sometimes it is known as Gas Metal Arc welding. Gas metal arc welding is a group of Arc welding process in which the workpieces are joined by the heat obtained from an electric arc struck between a bare uncoated consumable electrode and.

These gases will protect the join area from oxidation and generates multiple welding material layers. What is MIG Welding. The principle Of Tungsten Inert Gas TIG Welding Process This chapter presents the principle of tungsten inert gas TIG welding process besides important components of TIG welding system and their role.

Gas metal arc welding GMAW is a fusion welding process. What is Metal Inert Gas MIG Welding. MIG Metal Inert Gas Or Gas Metal Arc Welding GMAW is a welding process in which a consumable metal electrode is used to produce the electric arc to join the metal pieces together in the environment of a shielding gas.

Metal Inert Gas Welding This chapter presents the basic components and principle of metal inert gas welding MIG and pulse-MIG welding process with help of suitable schematic diagrams besides the influence of welding parameters in melting rate and metal transfer.

Mig Vs Tig Welding Types Materials And Applications A Guide

Mig Mag Welding Process Oerlikon

Metal Inert Gas Welding Process Download Scientific Diagram

Metal Inert Gas Mig Welding Of Aluminium Alloys The Principles And The Process

Mig Vs Tig Welding Types Materials And Applications A Guide

Mig Welding Techniques Or Metal Inert Gas Welding Techminy

What Is Mig Welding Process Or Gmaw Gas Metal Arc Welding The Welding Master

Metal Inert Gas Welding Mig Gmaw Substech

0 comments:

Post a Comment