How close to the cyliders are these engine mounting tabs youre trying to repair. Is it possible to weld cast aluminum.

Bsa Bantam Engine Case Welding And Machining Repair By Www Aquablast Uk Com Youtube

Perhaps a call or email to BMW would help.

Welding aluminum engine case. This is due to the intensive and tight geometrical area of heat input. Ad Find China Manufacturers Of Aluminum Welding. I use 4043 for almost everything seams to work best when welding cases intake manifolds and cylinder heads think its the best for dirty aluminum the pulse controls on tig help a lot when welding dirty aluminum since gets hot get imperaties to surface then give aluminum to cool and not melt away.

Ad Overhead Ambient or Portable. So I decided wed tackle a weld repair on this cast aluminium cast aluminum for my. Mag corrodes in the air even faster.

These engine cases can also be welded by a gas process named aluminum brazing. Frank Armao was an active member of the AWS D1 Committee chairman of the AWS D1 Aluminum Subcommittee and member of the Aluminum Association Committee on Welding and Joining. Shielded metal arc welding SMAW.

Welding the cast aluminum isnt a problem. 02 getting the oil out of the pores to weld is a PIA. This type of welding could be used to weld aluminum but is not recommended.

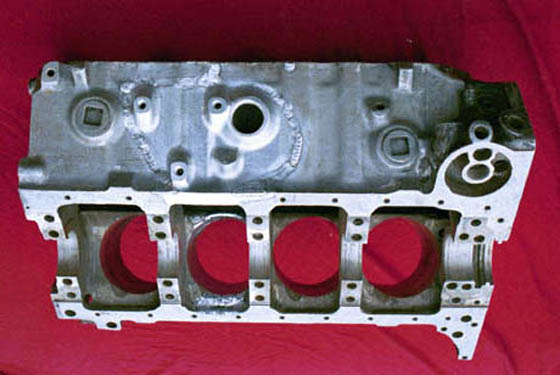

They can also be gas-welded by a process called aluminum brazing. Mar 14 2019. These motor mount brackets are available to purchase at a reasonable price however the engine cases need to be split to remove the bracket.

Aluminum engine case welding with standard 120 amp mig welder cracked sump leaking oil Honda super four motorbikeDisclaimerDue to factors beyond the cont. Cast will weld with 4043 and 5356 filler wires. Then the TIG welding torch is applied with some aluminium filler rod to repair the damaged cases.

In some cases it is used to repair cast aluminum using a constant current equipment with an aluminum electrode using electrode positive polarity. I recommend and use TIG. It allows actually to weld greater wall thicknesses eg.

It becomes a BIG job. Just grinding alone will tel you the diff between Alum and Mag pre and post is bullshit and a waste of time first and foremost you dont want anymore heat build up on an engine than can be helped welding will impart a local heat far more than normal conditions as it is for a shop that does repair work on a regular basis this is an easy fix but for your uncles buddys brother in laws cousins neighbor it could be a problem you know the guy who says he welded. I usuually use 4043.

In case of cracking. Also if it sJUST a seep drill the hole clen it a LOT with brake clean and get some motoseal from the parts store and seal it with that. Electrostatic Precipitators Disposable Media and Reverse Jet Cartridge Dust Collectors.

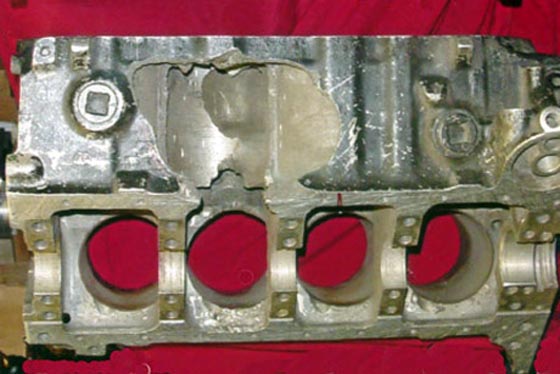

I used a workshop for this and had to remove all the engine main studs so that it could be. Aluminum engine cases can be Stick welded MIG welded or TIG welded. After cleaning the joint I heated the case in the oven set at max temp Wife not at home obviouslyand went for it in one.

Ad Find China Manufacturers Of Aluminum Welding. These are available from Armour supplies Ltd in Hastings East Sussex UK. Electrostatic Precipitators Disposable Media and Reverse Jet Cartridge Dust Collectors.

I have encountered some motorcycle cases that are magnesium IF you ever do Use A-10 mag rod and go at it just like it is aluminum. Cast aluminum motor blocks without the need to preheat or remove them prior to welding. Withe the case welded so that the main gantry was plugged I was able to get the case re taped with the 3 8 NPT tap.

Yes you can weld most cast aluminum. Ad Overhead Ambient or Portable. He also was the author of The WELDERs Aluminum Workshop column from 2001 to 2020.

But yes most cast aluminum are weldable though there are factors you need to pay attention to. But I know some welders who swear by 5356. But significant difficulties in case repairing are the high thermal conductivity and the low melting point of metal due to which distortion occurs.

Its being used in a wide field where submarine- or in general large ship motor blocks have to be repaired eg. My one and only attempt at ally welding was on a honda motorcycle case a CD200 it had broken where the kickstart went into the case. One is the filler.

There are many ways to weld aluminum engine cases like it can be done with a stick welder TIG welder and MIG welded. Because of the high thermal conductivity and low melting point distortion and burn-through are common when welding aluminum cases. Yep it smokes like crazy and will leave the weld covered in smoke But once you wire brush it it will look magnificent hahahah Pun Intended.

I used the proper mixed gas for the mig with ally wire installed. Firstly when aluminium castings are welded like crankcases it is important to first heat them in an oven to bring them nearer to the welding temperature. The thing is these alloys are used in places where they come in contact with dirt.

The actual percentage being 8 Aluminium to 92 Magnesium. Personally id do the last if it was my mower. However understand that welding cast aluminum might not be the easiest of tasks in most cases and it could be as a result of impurities.

That does work its case sealant for aluminum cases very similar to 1304.

Aluminum Engine Block Repair Build And Tune

Welding Engine Cover With Durafix Aluminum Youtube

Aluminum Engine Block Repair Build And Tune

Aluminum Engine Block Repair Build And Tune

0 comments:

Post a Comment