Sureweld 55 Cast can be used for build up surfacing or joining of cast iron parts. Consult pipe manufacturer for recommenda-tions.

1kg Cast Iron Welding Electrode Rods Welding Rods Aliexpress

In MIG welding the electrode wires are usually nickel or Monel but copper alloys may be used.

Welding electrode for ductile cast iron. Brazing isnt really welding as it doesnt fuse the metal as a weld does. Electrode having a pure nickel core wire designed for the welding of cast iron with preheat. This is the lowest cost electrode for welding cast iron and the electrode has a very user-friendly arc.

The electrode is espcially useful for welding heavy sections and high-phosphorus irons. Consult pipe manufacturer for recommendations. ENi-CI or simmilar Cooling down following welding should also be done very slowly.

For Welding-ductile-iron of the high strength grades the nickel-iron-manganese electrodes designated ENiFeMn-CI can be used. Cost machine-ability and whether the weld is single or multiple pass. Ferroweld AWS class ESt is a lower cost steel electrode.

Flux cored wires nickel-iron and nickel-iron-manganese wires are also available for welding cast irons. Suitable for welding grey cast iron white and grey mallable cast iron nodular cast iron. It can tolerate welding on castings that cannot be completely cleaned before welding.

Powders are based on nickel with additions of iron chromium and cobalt to give a range of hardnesses. For reparing cracked an worn castings or joining cast iron parts to components made of steel copper and nickel materials. Superior crack resistance welding of gray ductile and SG castings where high strength is requiredexcellent machinability.

NI-ROD 55 Welding Electrode is used for shielded-metal-arc welding of grayductile malleable and Ni-Resist cast irons. This universal electrode can be used to weld a wide variety of malleable ductile and nodular cast irons. Utility of the Fe-Ni-Mn system in welding ductile iron.

These are suitable also for wear resistance applications and for surfacing or buildup of worn out parts. The 44- and 55-percent nickel-iron electrodes. This iron cant be welded because welding can change the properties of the metal.

Choosing electrodes for welding cast iron typically comes down to three things. Some electrodes recommended for welding Ductile Iron are the 44- and 55-percent nickel-iron electrodes. It is also used for welding cast irons to various wrought materials including carbon steels low-alloy steels and nickel alloys.

Some electrodes recommended for welding Ductile Iron are the 44- and 55-percent nickel-iron electrodes. It is an all-position electrode suitable for repair welding nodular and ductile cast iron grades including the high strength spheroidal graphite irons. Provides maximum security against cracking.

Electrodes to be AWS A515 class E. The weld deposits are hard and are not machine-able but can be finished by grinding. Its a good option to minimize the extreme heating and cooling of the electric welding processes and its easier to maintain the temperatures of the components with it.

These electrodes provide weld metal strength and toughness properties that are comparable to those of the base iron. Elbana studied the effect of preheat on weldability of cast iron using welding electrode ENiFe-CI it is concluded that DCI can be welded with and without preheat and the mechanical. Oxy-acetylene welding is another option frequently used to weld cast iron.

Our civil engineers want to weld a fabricated A36 bracket either side of a joint of some ductile iron pipe 48 dia AWWA C151ANSI A2151 to anchor tie rods crossing the joint to keep the joint closed when the pipe is exposed temporarily. Can be used to weld malleable iron and ductile iron to itself or dissimilar metals. Sureweld 55 Cast has good tolerance for the high.

Gas metal-arc GMA gas tungsten-arc GTA shielded metal-arc SMA and submerged arc SA welding processes were evaluated using Filler Metal 44 and Welding Electrode 44 with 19 mm 075 in thick sections of. Nickel is expensive and so therefore is this premium electrode. This cast iron is very hard to weld but it is the most common type of cast iron that is welded.

These electrodes provide weld metal strength and toughness properties that are comparable to those of the base iron. This iron is rarely welded because it is quite expensive and a slow process. Around 500 - 600C When using these high pre-heats you can use a standard E7018 electrode although I would still use an electrode dedicated to welding cast irons.

75 is a non-conductive nickel iron welding rod formulated to join dirty and contaminated cast irons. In addition it is ideally suited for the repair of defective or cracked malleable iron castings. Pipe will be abandoned after construction of the main line.

Tech-Rod 99 AWS class ENi-CI is a nominally 99 Nickel electrode. The 44- and 55-percent nickel-iron electrodes should be in conformance.

77 Non Cracking Cast Iron Welding Rod

Cast Iron Welding Rods Weldequip

1kg Murni Nikel Las Cast Iron Rod Besi Cor Nikel Besi Elektroda Nikel Tembaga Las Cast Iron Rod Welding Rod Rod Weldnickel Electrodes Aliexpress

Nikel Murni Las Cast Iron Rod Besi Cor Nikel Besi Elektroda Nikel Tembaga Las Cast Iron Rod 2 5mm 3 2mm 4 0mm Batang Las Aliexpress

Electrodes Used For Ductile Iron Welds Download Table

Esab Ok 92 58 Cast Iron Electrodes Gasweld

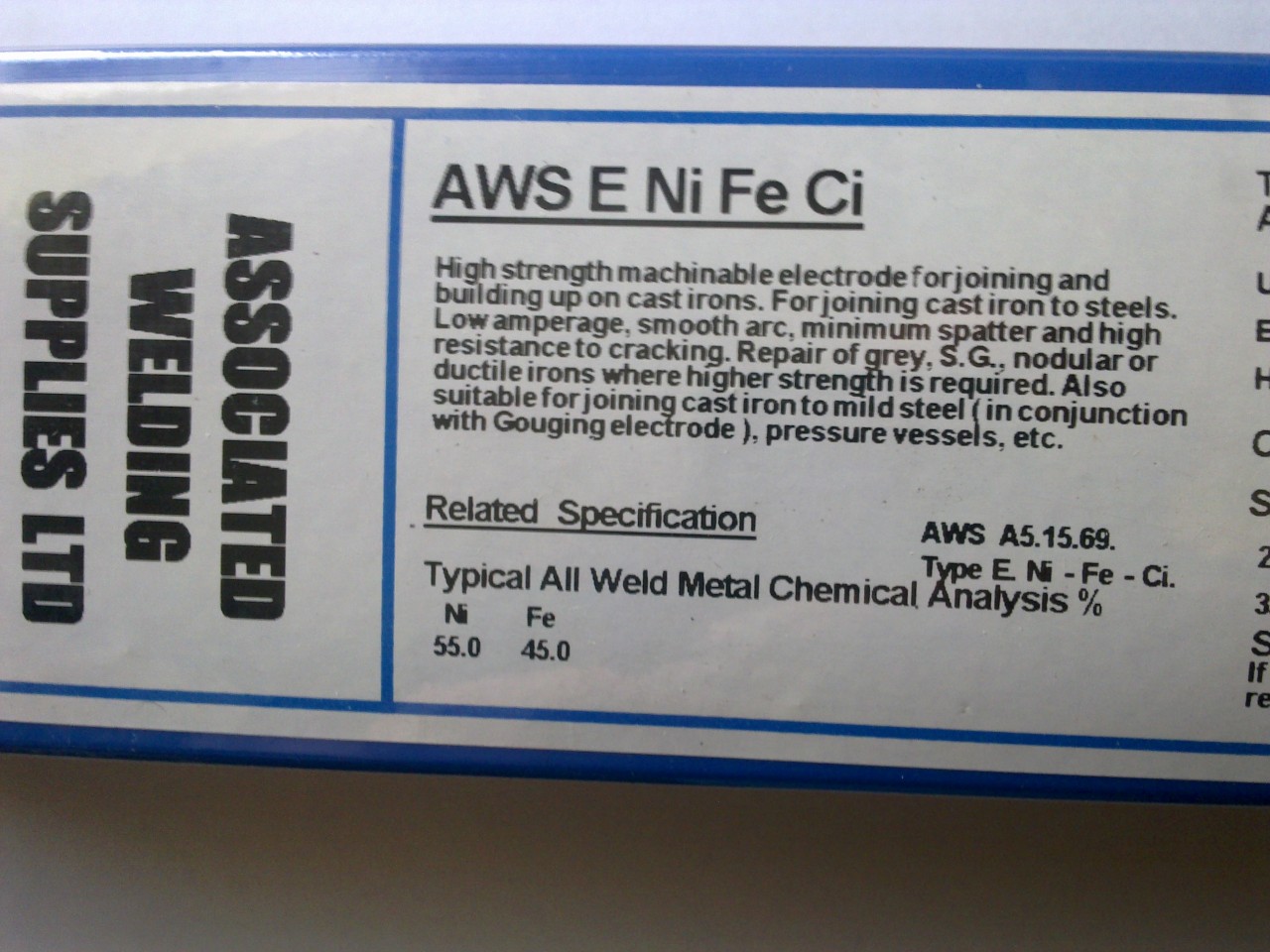

2 5mm Nife Cast Iron Electrodes X 1 Kilo Associated Welding Supplies Ltd

Cast Iron Welding Electrode At Rs 500 Kilogram Cast Iron Welding Rod Id 17502910348

Cast Iron Welding Rod China Manufacturer Cast Iron Welding Rod China Manufacturer Cast Iron Welding Rod China Manufacturer

0 comments:

Post a Comment