Pressure welding uses heat along with impact-type. A 2lb spool of wire doesnt cost much.

Stainless Steel Fcaw Without Gas Youtube

Lincoln Blue Max FC-308L is a gas-shielded flux-cored stainless wire and uses either C-25 or 100 CO2.

Welding stainless steel exhaust with flux core. You can mig weld stainless with good results as long as the weld joint is CLEAN and you use a stainless wire with the right shielding gas. But where you dont care about the look of your stainless steel. To melt your stainless steel and your mild steel flux core welding wire.

Thermit welding uses a chemical reaction to produce intense heat instead of using gas fuel or electric current. Tools we use in the shopMarkal Pro Mechanical Pencil. As flux core welding is not highly recommended by professionals to repair an exhaust tube but it still can use for the DIY fix the muffler.

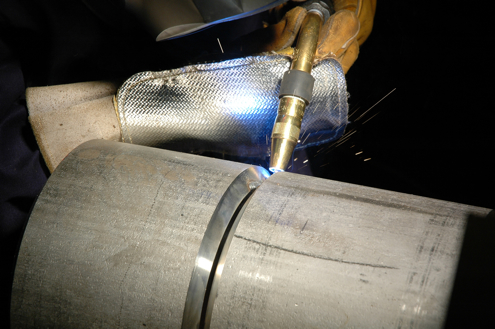

The arcs tend to be hotter when flux-core wires are used and thus you should wear gloves with forearm protection to protect your skin from the heat. For proper MIG stainless steel welding argon or another capable shield gas is required. Self-shielded flux-cored welding differs from MIG welding in that it doesnt require an external.

Wear welding goggles to protect your eyes from the UV rays and the heat. Well I found 035 stainless steel flux cored wire so Ill give it a try. Self-shielded flux-cored welding can be an excellent process to use for welders of all skill levels who frequently need to weld outside or on dirty material.

Stainless steel can be welded with flux core wire but not like TIG and other arc welding processes. Can You Weld Stainless Steel With Mild Steel Flux Core Wire. Httpsamznto2S0rOH1Markal Pro Refills Silver Str.

3- Use Flux Core Welding for Exhaust Pipe. Httpsamznto38M62NqMarkal Pro Refills Red. Its not overly expensive to get a smaller roll of flux-cored wire for small jobs and you dont need to change around your cylinders.

Welding over slag can make the welds look really nasty and fuse like crap. Its a tri-mix of Helium Argon CO2. Either way to get the best service and longest life out of a stainless steel exhaust system its important to weld stainless steel exhaust with a matching or at least similar filler metalnot cheap carbon steel mig wire.

Gas or oxy-fuel welding uses a flame from burning a gas usually acetylene to melt metal at a joint to be welded and is a common method for welding iron steel cast iron and copper. Keep the cup maximum of 12 inch away from the material from welding and make sure your gun movement is at a nice steady pace ie not too fast not too slow. This Stainless header is off a Honda car and the collector was welded using a mig gun and plain carbon steel wire.

Self-shielded flux-cored welding is a wire welding process in which a continuous hollow wire electrode is fed through the welding gun into the weld joint. Either use some scrap that you have left over or buy a little extra to practice with. But there are some things for you to bear in mind.

A 7525 argonc02 or straight Argon gas will produce a weak weld joint. Safety Tips For Flux Core Weld Exhaust. 99 10 coupon applied at checkout Save 10 with coupon.

There is more spatter produced when welding using flux-core welding wires. If I have to spend a bunch of time with a grinder and sander to get the pipes looking nice so be it. You can use a flux core welding method to weld stainless steel and get a nice and clean weld.

Just remember to get the settings right for amperage and wire feed. And your flux core welder must be capable of outputting at least 90 Amp. A flux core mig will work just fine for exhaust.

VILLCASE Mig Welding Wire-08mm 1kg Stainless Steel Welding Wire Spool Gasless Flux Core Welding Wire for Soldering Silver 2999 29. An A1025 shielding gas is your best bet. And the flux core welding wire to use is type 309L stainless steel flux core welding wire.

Gas for MIG welding stainless isnt the same as the gas you use for carbon steel. I work for a welding supply company. Welding stainless steel with mild steel flux core wire will give you a weld that rusts.

Since its flux core youll need to chip off any slag after you weld. When flux core welding however it is advisable to clean the tubing to reduce the resulting spatter produced. Im a hobbyist Im cheap and Im willing to give it a try.

Depending on the thickness of the tube turn the heat down and wire speed up a little. You need to weld stainless outside in windy. And your weld cracking.

Exhaust Pipe Welding using Flux Core Welding While not a highly recommended way to repair your exhaust pipe you can still use gasless flux-core welding to DIY fix your muffler. Smalles roll is 03510 spool for just under 9000 ESAB manufactures Core-Bright self-shielded wire available in 045 564 dia. Its easier to weld stainless steel with flux core welders because you control less mechanism.

And you can find 309L flux core stainless steel wire that needs no tank of compressed gas to protect your weld. You are not welding for strength factor but to fill the gaps unless the exhaust is part of your roll cage LOL. Before using flux core welding be sure to clean the tube to decrease the spatter producing result.

Jual 1 Roll Stainless Steel Gasless Mig Welding Wire 08mm 1kg Flux Cored Jakarta Barat Hasanstore1 Tokopedia

Why Only 50amps Learning To Tig Weld Stainless Steel Big Clear Tig Cup Youtube Welding Projects Welding Training Welding

Solution Welding Flux Cored Rods Vrsgs Welding Flux Welding Aluminum Aluminum Molding

What Is Flux Cored Arc Welding Fcaw Youtube What Is Flux Flux Cored Arc Welding Arc Welding

Stainless Steel Welding Techniques With Mig Flux Core Spawanie Stali Nierdzewnej Mig Mag Youtube

How To Mig Weld Stainless Steel Exhausts With Flux Core Youtube

Welding Stainless Steel Tube And Pipe Maintaining Corrosion Resistance And Increasing Productivity

Pin On Stainless Steel Projects

0 comments:

Post a Comment