It is made on test pieces intended for destructive testing. Weld testing even if not required by specifications helps welders to check and improve their own technique.

Radiography Test Rt Welding Ndt

Notch-toughness tests to determine the notches of welding.

Welding test meaning. For this reason a Welder should always be provided with a Welding Procedure Specification WPS to follow when performing the Welder test. The intent with the Welder test is to demonstrate that the Welder has the necessary skill to deposit a sound weld when following a qualified welding procedure. 23 Mar 78 SR 6178 s1.

Welder Qualification Test or WQT is a process of assuring the quality of a welders work. This makes the weld a horizontal weld. The 2G test for pipe welding is done on a test piece in the vertical position.

Pipe welding is a bit of a different animal. Welding-codes describe the types of construction they are concerned with. Practice every type of welding methods metals thickness and all body positioning working space clearance and weather conditions you could be tested on.

The liquid penetrant test is one of the most widely used Non-Destructive Test NDT methods. By this test method. Many different people across an organization must be able to write andor interpret welding symbols.

This test can be used to replace the mechanical test in qualifying the performance of groove type welding to prove the ability. Testing of welds is used to verify that the welding procedure is under control. Welding-testing is used to determine the soundness of welds.

It is another form of a 6G test. In the welding field accuracy of work matters more than anything else. The completed welded joint may be referred to as a weldment.

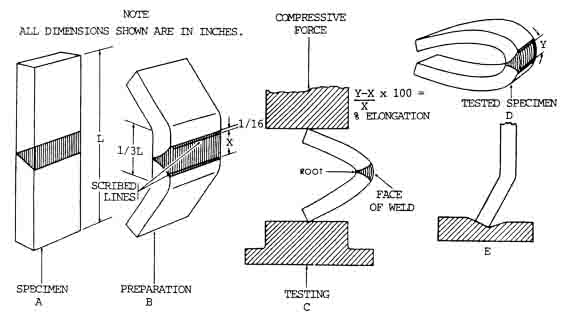

Fillet-weld tests to determine the size contour and degree of soundness of the fillet type welding joints. It can be used to inspect almost all non-porous materials such as metals plastics ceramics etc. WELDING SYMBOLS TEST YOUR KNOWLEDGE Welding symbols are used to communicate vital information about welding requirements.

Welding Symbols And Their Meaning Explained Through Examples and Charts. The letter R stands for restricted. Welding is a fabrication process whereby two or more parts are fused together by means of heat pressure or both forming a join as the parts cool.

It means the weld is performed in a ring mode by placing a steel plate below the weld site with an inch gap. Individual welders are certified with a qualification test documented in a Welder Qualification Test Record WQTR that shows they have the understanding and demonstrated ability to work within the specified WPS. For example in the Pressure Equipment Directive DIN EN 1090 and the Machine Directive etc.

An artifical notch or a groove is intentionally introduced by a hacksaw or a cutting disc on the weld face along the primary axis of the weld. This method uses Charpy V-Notch and Drop Weight. Welding Certifications are technically a hands-on welder qualification test that is conducted by certified welding inspector that will determine if the person or machine can produce a sound quality weld up to the code or welding procedure needed for a Company job site or a particular industry standard.

There are several key differences in a 2G pipe weld test and a 2G structural weld test. No backer bar is used in a 2G pipe weld test. Welding Specifications cover requirements for voluntary adoption and no enforcement is meant unless they are agreed upon between procuring agency and contractor as spelled out in a Purchase Order.

It contains a joining method chart master chart of welding and joining processes joint types roots grooves welding position diagrams test positions bead types explanations of weld parts and sizes various weld profiles weld discontinuities current polarities. V welding test means the test of a welders ability to weld according to the procedures as outlined in these regulations and as approved. Basically this is another difficulty level for welders in the certification process.

We can only detect any surface discontinuity or irregularity such as surface cracks porosity pinholes etc. Weld Nick break test This test is performed to reveal internal imperfections such as slag inclusion lack of fusion incomplete penetration porosity etc in a butt weld. Guided bend test 2 Radiography Examination.

The usual steel plate. Welding is usually used on metals and thermoplastics but can also be used on wood. It is a working qualification test and every employer demands qualified welders.

One could say that Welding-codes are essentially enforced Specifications. A PQR is a record of a test weld performed and tested more rigorously to ensure that the procedure will produce a good weld.

1g 2g 3g 4g 5g 6g 1f 2f 3f 4f Pipe And Plate Welding Position Engineering Blog

Physical Weld Testing Destructive Nondestructive Weld Guru

The Process Of 4g Weld Testing How To Pass 4g Welding Test Welding Troop

Welding Certifications What They Mean How To Get One Welders Universe

Welding Certification Dont Even Get Me Started

The Welder Test Explored And Explained

The Welder Test Explored And Explained

The Process Of 4g Weld Testing How To Pass 4g Welding Test Welding Troop

Welding Certification Dont Even Get Me Started

0 comments:

Post a Comment