The best all-round method for Welding Cast Iron is arc welding. Preheat the cast iron before welding and go low on the heat and slow on the weld.

There are exceptions to this.

How to arc weld cast iron. Yes cast iron can be welded to steel. Preheating the cast iron part before welding will slow the cooling rate of the weld and the region surround the weld. Selection of welding technique.

Stick welding is one of the most common and dominating welding processes to weld cast iron. First usually you are doing a repair job or a retrofit if you are asking about welding cast iron to steel so be sure to check the parts thoroughly to ensure there are no stress cracks or other signs of damage. Selection of preheat temperature.

Generally cast iron can be stick welded by preheating the material to 350F before welding and adding a slow cooldown phase in an insulating medium like sand to prevent heat cracking. Take your time heating it. Pre-Heating Cast Iron Using a blowtorch remains a comfortable way to get cast iron preheated.

There are two common types of Cast. Identification of the alloy. There are numerous answers on best way to weld cast iron.

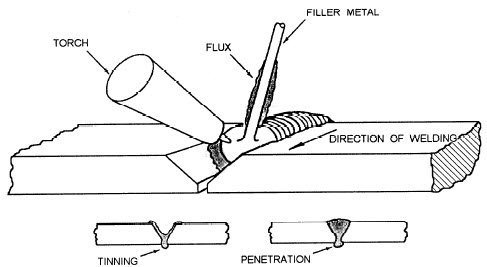

Oxy-acetylene welding is another option frequently used to weld cast iron. Also move slowly in a stitch-like manner. Typical preheat temperatures are 500-1200 degrees F.

Gas welding Arcstick welding MIG welding and TIG welding are the four widely used methods to weld a cast iron. Control the expansion and contraction of your cast iron workpiece s. While this is the short answer there is a bit more to unpack to tackle this bit more challenging stick welding project.

Dont heat over 1400 degrees F since that will put the material into the critical temperature range. Normally when you are learning how to weld Cast Iron you would pre-heat the base metal to at. Iron starts to glow dull red at about 900 degrees F.

Use the appropriate rod type. Cast iron Welding Rods have a special Graphite rich flux this graphite chemically ties up the Carbon in the Cast Iron limiting migration into the weld metal and heat affected zone. WelddotcomIn this episode we take a look at welding Cast Iron.

So if you get your rosebud torch on it and let it just start to glow then you know youre at a good temperature for welding. Use only low current which will minimize residual stress and admixture. Brazing isnt really welding as it doesnt fuse the metal as a weld does.

However there are a few things you want to remember when welding cast iron to steel. Following is a brief explanation of each. Ensures a little preheat at room temperature.

However we are discussing the most used and popular techniques for welding cast iron. Prepare the job with a groove in U. Its best to do this inside in a darker area so that youll notice when it starts to glow.

Your mission to accomplish how to weld cast iron parts can save your money and time. This has to do with the electron flow and the control of heat. Run a bead across each part of the crack.

Its a good option to minimize the extreme heating and cooling of the electric welding processes and its easier to maintain the temperatures of the components with it. ArcStick Welding is arguably the best all-round process for Welding Cast Iron provided the correct welding rods are used. A special Graphite rich flux is present in cast iron welding rods.

Preferred by most DIY welders arcstick welding can be the most effective way to weld cast iron if the right welding rods are used. The inhouse-weld of cast iron needs thorough research in four key steps to know how to weld cast iron. Different Techniques To Weld Cast Iron.

The most important thing to remember when welding cast iron is to move low and slow. Its very important to pre-heat the cast iron gently to minimise thermal shock particularly if youre welding with cast iron rods. By doing this 23 of the heat generated will be in the work piece and 13 in the electrode.

Dont pre-heat cast iron beyond 760C 1400F. Its a form of arc welding. While you can use TIG MIG or ARC we recommend ARC.

The higher your heat treatment the longer itll take your workpieces to cool. The process is extremely simple and there are tons of electrodes available for the different jobs. Limit weld quantity in one run.

You can use stick welding for effective joints and its very economical. The welding rod should be in a vertical direction. Thorough cleaning of the part.

Notably cast iron is sometimes welded positive return to keep the work piece as cool as possible. Ensure you get your cast iron heated to around 250 700ºC. It is always preferred to heat the entire casting if possible.

What is the best way to weld cast iron. Work on one inch at a time and allow about 45 seconds for.

Stick Welding Cast Iron Repair Using 7018 Welding Rods Youtube

Stick Welding Cast Iron Repair With Muggy Weld Youtube

Welding Cast Iron The How To Guide

The Welding Factors Of A Cast Iron Fully Depend On The Material Type Complexity Thickness Casting Complexity And Need Welding Cast Iron Tig Welding It Cast

Mig Welding Broken Cast Iron Youtube

Best Cast Iron Repair Service Near Me Ampweldingfabrication Com

How To Weld Gray Cast Iron Cast Iron Welding Guidance

0 comments:

Post a Comment