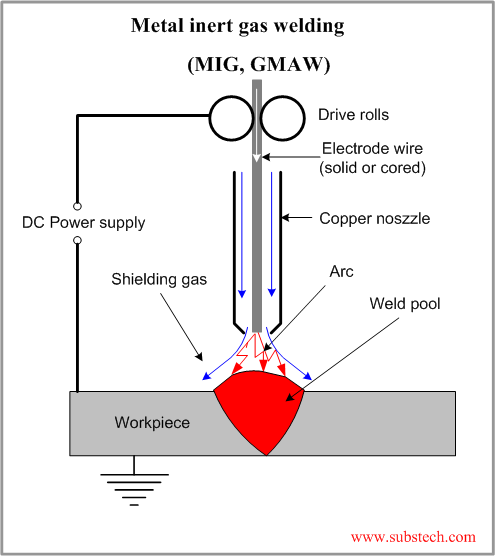

What is metal inert gas MIG welding. In the metal inert gas MIG welding process an electric arc is struck between the filler wire and the work piece while a shroud of inert gas shields the electrode and protects the molten pool against oxidation.

Mig Vs Tig Welding Types Materials And Applications A Guide

Argon helium carbon dioxide or a combination of these inert gases are commonly used in MIG welding.

Principles of inert gas welding mig. At this point the welding gun is carrying current. This process is also known as gas tungsten arc welding. The two base materials are melted together forming a join.

Metal Inert Gas MIG welding is an arc welding process that uses a continuous solid wire electrode heated and fed into the weld pool from a welding gun. In this welding process the heat required to form weld is provided by a very intense electric arc which is form between tungsten electrode and work piece. Inert Gas - Inert gases tend to have full outer electron shells making them non-reactive.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. A continuous electrode the wire is fed by powered feed rolls wire feeder into the weld pool. Working principles of MIG welding This welding process is achieved when a cable from either AC or DC power supply is connected to a consumable electrode welding gun and the earth cable is placed on the workpiece.

The shielded gases are also supplied through nozzle which protect the weld zone from other reactive gases. In this welding a non-consumable electrode is used which does not melt. The gun feeds a shielding gas alongside the electrode helping protect the weld pool from airborne contaminants.

It is similar to the other arc welding processes where a consumable electrode is used to melt and join the metals. Ad Find China Manufacturers Of Mig Welding. MIG welding is an arc welding process which is shielded by an external gas welding argon helium co2 argon oxygen or other gas mixture It uses consumable electrode wire which has a chemical composition similar to the parent material.

The continuous evolution of the MIG or Metal Inert Gas welding technology assisting the MIG welders in improving their welding skills. MIG or Metal Inert Gas welding is a special type of welding used for non-ferrous metals. Metal inert gas MIG welding is the first choice for many manufacturing industries for many reasons but the fast creation of top-notch welds is certainly the main advantage of this technique.

Tungsten plasma arc welding PAW inert-gas tungsten-arc welding TIG whereby TIG welding is the most widely used fusion welding process for aluminium. 2 The wire is supplied on a reel and is fed to the welding gun by the drive rollers. The arc is formed in the gap between the metal and the electrode.

Mig works on same principle of TIG or arc welding. The basic principle of MIG Welding is an arc is maintained between the end of the bare wire electrode and the work piece where the heat source required to melt the. Metal Inert Gas MIG Metal Active Gas MAG welding refers to a group of arc welding processes that use the heat generated by a DC electric arc to fuse the metal in the joint area.

The principle Of Tungsten Inert Gas TIG Welding Process This chapter presents the principle of tungsten inert gas TIG welding process besides important components of TIG welding system and their role. What is Metal Inert Gas MIG Welding. TIG stands for tungsten inert gas welding or sometimes this welding is known as gas tungsten arc welding.

The metal shielded-gas welding is limited to the metal inert-gas welding process. 1 The arc is struck between the workpiece and a metal wire electrode that is continually fed forward into the arc. The plasma welding consists only of the plasma-arc welding process which works with a transferred arc.

An electric arc is created between the tip of the wire and the. This heat is further used to melt consumable electrode and base plates metal which solidify together and makes a strong joint. Generally a smoothed direct current power source is used.

It works on basic principle of heat generation due to electric arc. The type of shielding gas can directly affect the quality and strength of the weld so you must choose based on the type of metal being welded. It is also referred to as MAG welding Manual Metal Arc Welding.

PRINCIPLE OF MIG WELDING Gas Metal Arc Welding GMAW is commonly referred to as MIG welding Metal Inert Gas welding. Whenever it is placed closed to the workpiece an arc is produced. Ad Find China Manufacturers Of Mig Welding.

It is also known as Gas Metal Arc Welding or GMAW. The core principle of MIG welding is an arc that is maintained between the end of the bare wire electrode and the work piece where the source of heat is required to melt the parent metal is obtained. It also requires minimum skills which makes it suitable for newbies who are looking for a relatively uncomplicated and cost-efficient way to get high.

Principle of MIG Welding The GMAW welding process works on the following principles.

Gas Shielded Arc Welding Processes Tig Mig Mag Openlearn Open University

Metal Inert Gas Mig Welding Of Aluminium Alloys The Principles And The Process

Mig Vs Tig Welding Types Materials And Applications A Guide

Mechanical Engineering Gas Metal Arc Welding Gmaw Or Mig Welding

Gas Shielded Arc Welding Processes Tig Mig Mag Openlearn Open University

Metal Inert Gas Welding Mig Gmaw Substech

.jpg)

Mig Welding Equipment And Principles

Difference Between Mig And Tig Welding The Welding Master

0 comments:

Post a Comment