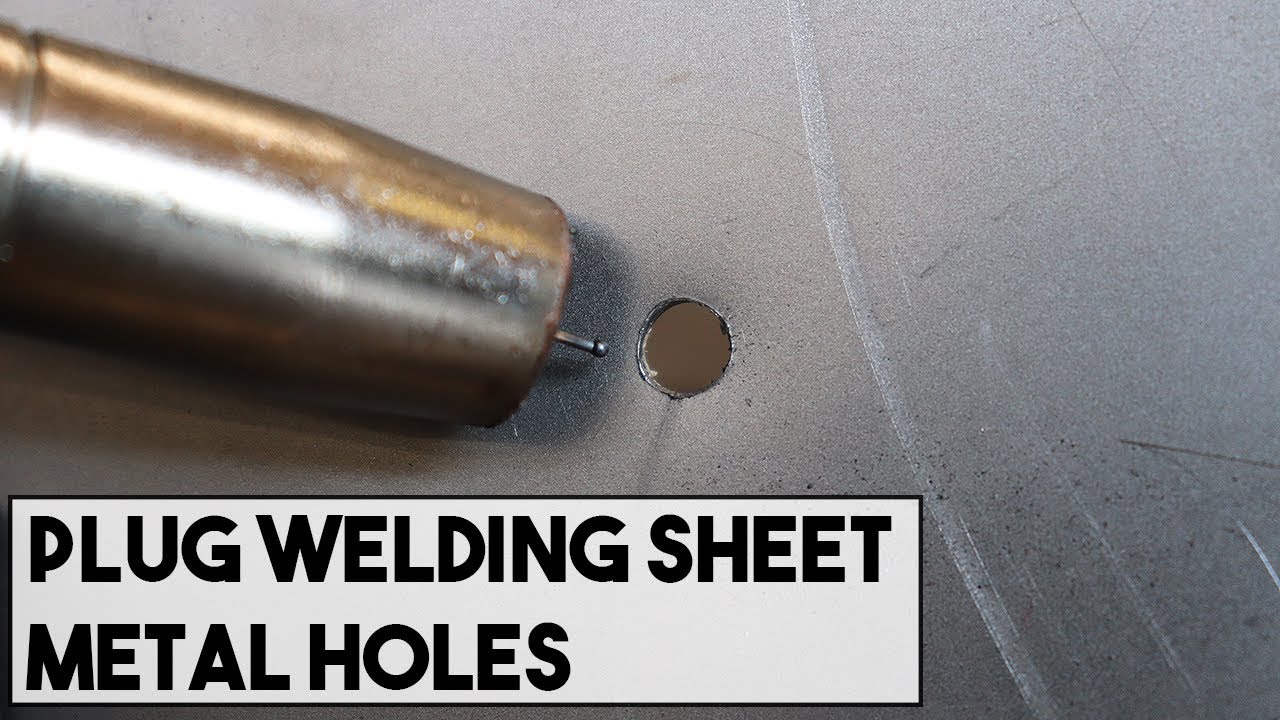

Regardless of the reason you will have holes that need welded shut. This may be due to burning through the thin sheet metal welding molding holes fabrication or other reasons needed.

Once youre through with cutting and fitting the metal sheet into size use.

How to weld sheet metal holes. The second thing is lots and lots of practice the first thing you will need to master is striking an arc at very low amps and avoiding making holes in the sheet. And with Mig welding you risk blowing out more metal than you fill plus the weld can be as hard as a rock. The pedal regulates the heat output from your welding machine.

You can the panels to be pressed together quite tightly so that you get a strong weld between them. Apply a Suitable Power Setting and the Correct Foot Pedal TIG machines come with foot pedals under normal conditions. Just kidding this tip is to explain how to weld sheet metal with a stick welder.

Beside above can you drill and tap a MIG weld. Plug Welding Holes in Sheet Metal with Magnetic Copper Backers - Mike Finnegan at Hot Rod - Eastwood - YouTube. Make sure to use an electrode wire that is thinner as it uses lesser heat and prevents blowing holes on to the sheet metal.

Grind off the backs and bump out the shrinkage. Plug Welding Holes in Sheet Metal with Magnetic Copper Backers -. Cut out a bunch of little square pieces tack them on the back side fill the top up with filler metalits going to get hot and shrink of course.

Try using a piece of scrap metal the same thickness as the one you are getting ready to weld. 4-you could lead them. The real trick to weld sheet metal is to use a wire feed.

If you are going to weld on thin sheet metal such as car body parts then youre going to have holes to weld from time to time. Welding instructor Mark Prosser co-author of Full-Bore Welding walks ARC Magazine readers through the steps to repair a hole in thin-gauge steel. Allow the epoxy to cure.

You can also try padding to avoid making holes in the base metal. Apply epoxy until the hole is filled. Ensure that the sheet metal extends over the metal panel by at least two inches past the damaged spots edges.

Turned out fine despite the amount of time I spent on the trigger filling in my holes. Spot blast the back side of your welded holes the side you had the copper backing on or hit em with a wire wheel to get clean steel chamfer the holes youre filling with your roloc sanding disc epoxy prime DONT por15you cant go over it with anything unless you use their tie coat. Novice welders should understand that thinner wire needs to be used when MIG welding sheet metal.

Nonetheless before you use it to weld slimmer metal sheets you need to adjust the TIG machine to the ideal settings. Properly adjusting your MIG welder is key and you will avoid burning holes. Cut the selected metal to a size suitable for the spot to be mended.

Next spin off the gas nozzle on your MIG torch and spin on the Spot Weld Nozzle. We need to establish what is considered thin metal. The first is a DC welder which can go as low as 20-25 amps.

Then build up the epoxy above the surface of the metal and let it slightly overlap the edges of the hole. Thin-Gauge Sheet Metal Repair Video. A wire feed or tig welder is ideal for sheet metal but we will assume that you dont have one.

By comparison high temp soldering brazing is guaranteed to warp and buckle the metal. With the holes punched or drilled you can clamp the panel back together and take a set of spot weld pliers and clamp the seam or flange together tightly. Before you begin the process of welding a very thin sheet there are a few things you must have.

This technique isnt limited to filling errant holes drilled in sheet metal by using some ingenuity large hack jobs can be repaired and a. Try welding with a scrap sheet metal piece and practice many times until you start working on more important projects.

Hole Flares Metal Fabrication Custom Metal Fabrication Diy Welding

12 Tips For Drilling Holes In Metal Drilling Holes Drill Stainless Steel Sheet Metal

3 Tools For Creating Flanges In Lightening Holes Experimental Aircraft Youtube Metal Working Metal Workshop Metal Working Tools

How To Simulate Resistance Spot Welds Resistance Spot Welding Spot Welding Mig Welder

12 Tips For Drilling Holes In Metal Drilling Holes Metal Working Projects Metal Working Tools

How To Repair Rust Holes In Body Panels Sheet Metal Welding Urchfab Sheet Metal Metal Welding Welding And Fabrication

Speed Holes Dimple Die Metal Fabrication Sheet Metal Fabrication Metal Shop

Drilling Round Holes In Sheet Metal Metal Working Metal Tools Drill

0 comments:

Post a Comment