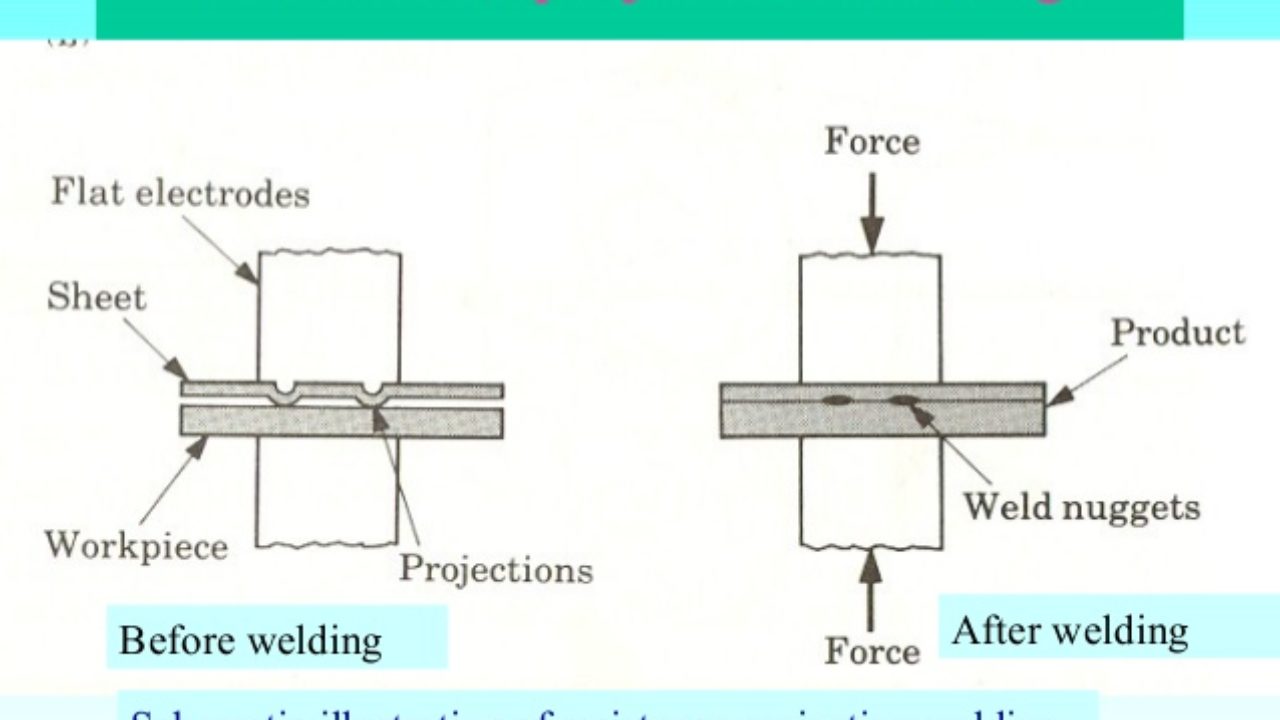

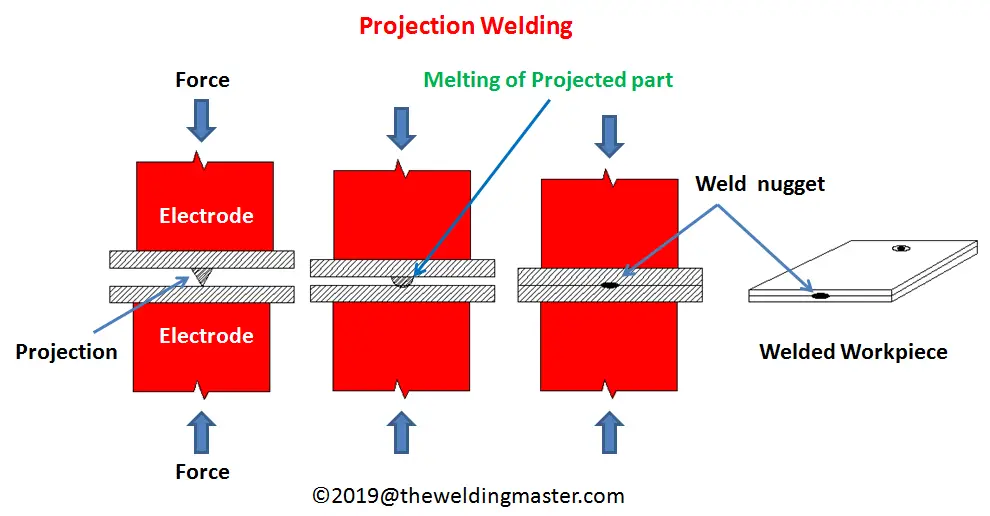

When projection welding substantial force is applied to the parts through the welding electrodes or dies. Projection welding electrode life is long when compared to spot welding electrodes.

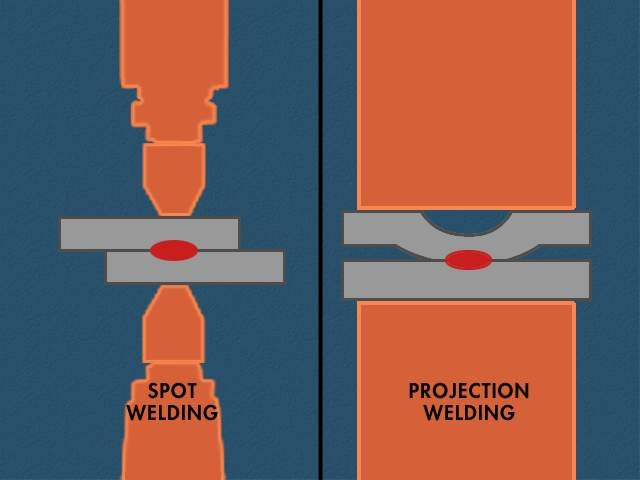

The part by design concentrates the current and force to create heat and forging at a concentrated location.

Projection welding is employed in. Maine labor trends point to significant growth in the welding technology field. Furthermore as current is passed through the system the heated and softened. 14 or 15 can be made by forming projections in.

It consists of two flat pieces that are side by side parallel. Welders work in a wide variety of industries from car racing to manufacturing. Its frequently utilized in electrical automotive and construction applications in part due to the strength of the welds it creates.

Texas California Ohio Pennsylvania Michigan and Illinois. Projection welding is a vari-ation of resistance welding in which cur-rent flow is concentrated at the point of contact with a local geometric extension of one or both of the parts being. I It is usually employed on punched where the projection automatically exists.

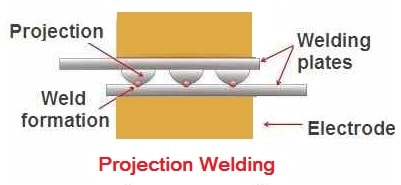

Projection welds developed via the resistance welding RW process use the design or shape of the part to make discreet individual-point contacts to concentrate the current during welding. The electrode delivers force and amperage through a relatively large surface area into the part being welded. Are Employment Projections Growing for Welding Industry Professionals.

Applications of Projection Welding. A number of welds can be made simultaneously. Welders cutters and welding machine operators held about 453000 jobs in 1996.

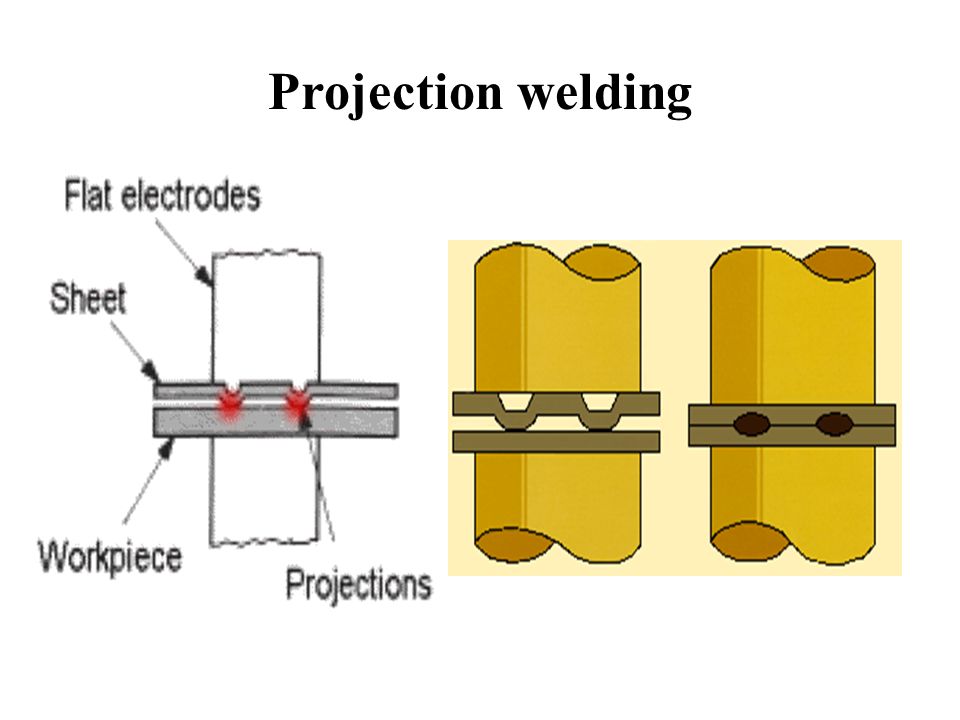

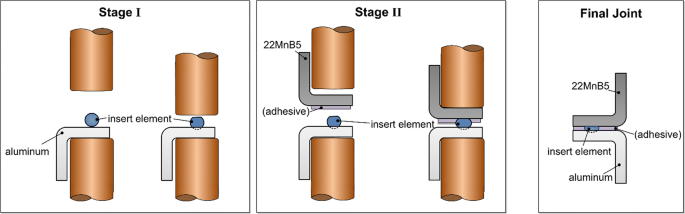

Projection welding is a resistance welding process of joining two sheets or a sheet and a thick component or a small component like nut to a big body like automotive chasis by making raised portions or projections on one of the components where weld nugget is required to be made. Projection Welding uses projections formed into the parts prior to welding in order to focus the weld current and create the weld nugget. Its the easiest and probably the most common weld there is.

The projections which can have single or multiple embosses of various shapes concentrate the welding current exactly where the joints need to form. Ii Small fasteners nuts etc. Iii Projection welding is used for welding of refrigerator condensers crossed-wire welding grills etc.

This projection-welding process employs projections formed onto one of the parts in this case the drawn cup to the right. Secondarily they provide cooling of the part. Projection welding is an ideal method of fastening attachments eg.

Welding also is used to join steel beams in the construction of buildings bridges and other structures and to join pipes in pipelines power plants and refineries. Brackets spigots and weld nuts to sheet metal where there is access from only one side and for making attachments to solid forged or machined parts. A lap Joint is formed when two pieces are placed in an over lapping pattern on top of each other.

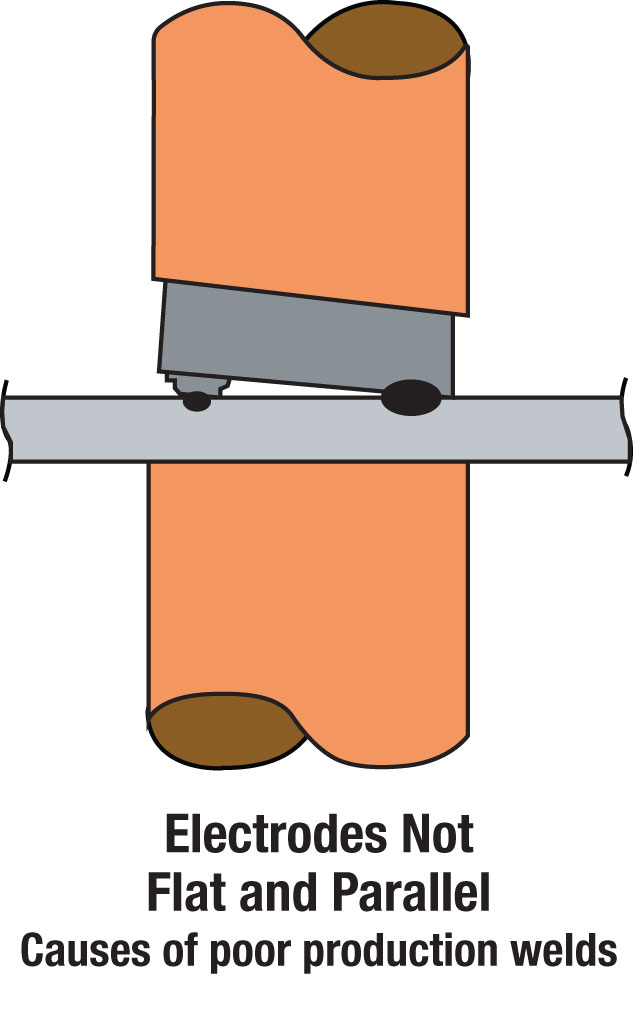

A large flat electrode on the face side can minimise marking as with spot welding provided that the mechanical wear of the electrode in the form of a shallow indentation is controlled. Of those nearly two out of five welders were employed in six states. The projection welding process is ideal for joining together metal components with embossments.

The table shows the number of welders and cutters employed in a variety of industries sorted by 2006 projected employment. If you are looking for a career choice or change chances are the ideals of stability security and opportunity are on your list of. The projection present in the material to be welded can be used for localisation of spot heating.

Posted on January 28 2019 - Posted in. Short length T joints eg. The theory of large deforma-tion is used to compute the excessive de-formation of the projection.

Projection welding is similar to spot welding but for the fact that the welding takes place at the projections on the surface of the metals and flat shaped electrodes are employed. Can be welded to larger components. The work that welders do and the equipment they use vary with the industry.

Projection welding can be employed and the projections are punched in the sheet opposing the face sheet. In most applications one of the workpiece surfaces features multiple small formed projectionsround dimples elongated ridges or rings or the extended corners of weld nuts. In most cases a projection is created at the required place by.

Week 2 Biw Fixture Basics Challenge Skill Lync

Resistance Projection Welding Engineers Gallery

What Is Projection Welding Working Principle Advantages Disadvantages And Application The Welding Master

Projection Welding Facts And Fundamentals Metalforming Magazine Article

Electric Resistance Welding Your Electrical Guide

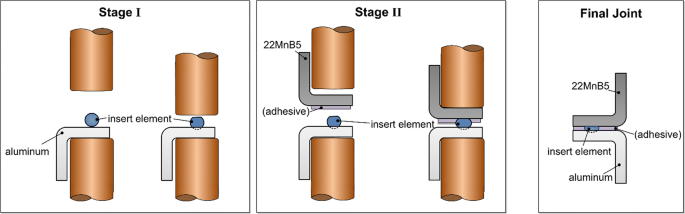

Novel Projection Welding Technology For Joining Of Steel Aluminum Hybrid Components Part 1 Technology And Its Potential For Industrial Use Springerlink

Projection Welding An Overview Sciencedirect Topics

What Is Projection Welding Advantages Application

What Is A Projection Weld How To Resistance Weld

0 comments:

Post a Comment