Ad Find China Manufacturers Of Aluminum Welding. So The tig welding project here is an aluminum diamond plate tank that will be used later for a new design tig water cooler.

Can You Use Argon Co2 Mix For Tig Welding Weldsmartly

MIG Welding Gas for Aluminum Welding.

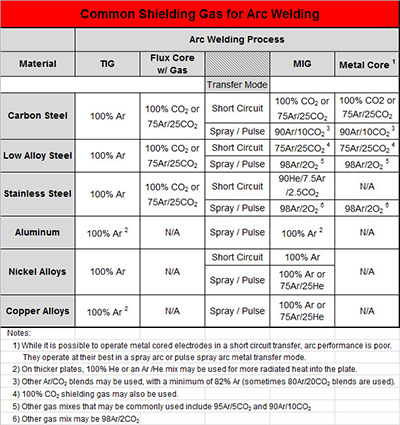

Tri mix welding gas for aluminum. For a short circuit transfer a tri mix gas consisting of. Pure mixtures of argonhelium are usually only used for nonferrous metals like copper and aluminum. For Stainless and aluminum TIG is a better bet IMO.

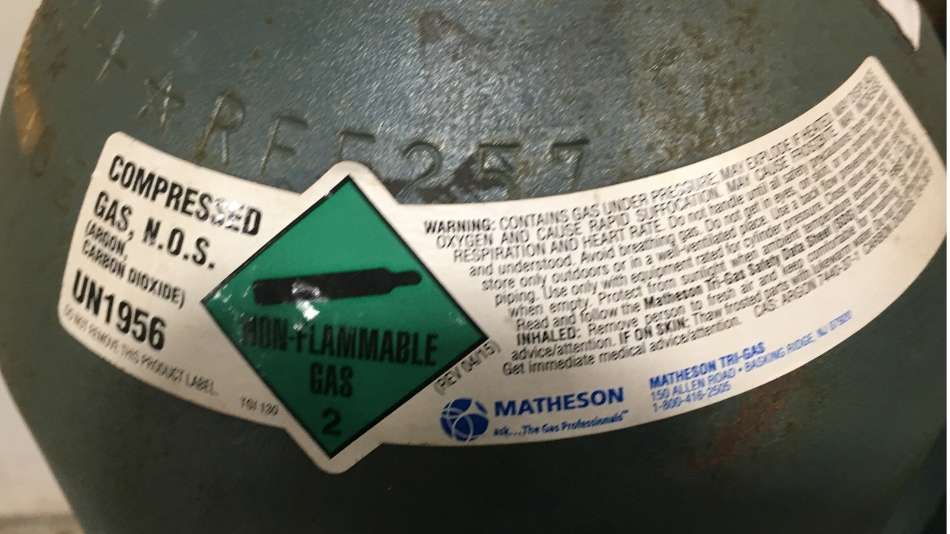

An argonhelium mix works well if you require deeper penetration or a faster travel speed. Since TIG welding requires 100 percent inert gas you could potentially use 100 percent argon gas for TIG welding while being able to use the same gas to MIG-weld thin aluminum less than ½ inch. Because 100 argon can be used to TIG weld all metals and thicknesses you only need one type of gas in your shop to handle all of your welding projects.

Argon offers good stability in your arc and doesnt require as much clean up afterward because the arc is narrow and concentrated. Mixtures of argon and helium are probably the next common and pure helium is generally only used for some specialized GTAW applications. The most popular type of shielding gas in TIG welding is 100 pure argon.

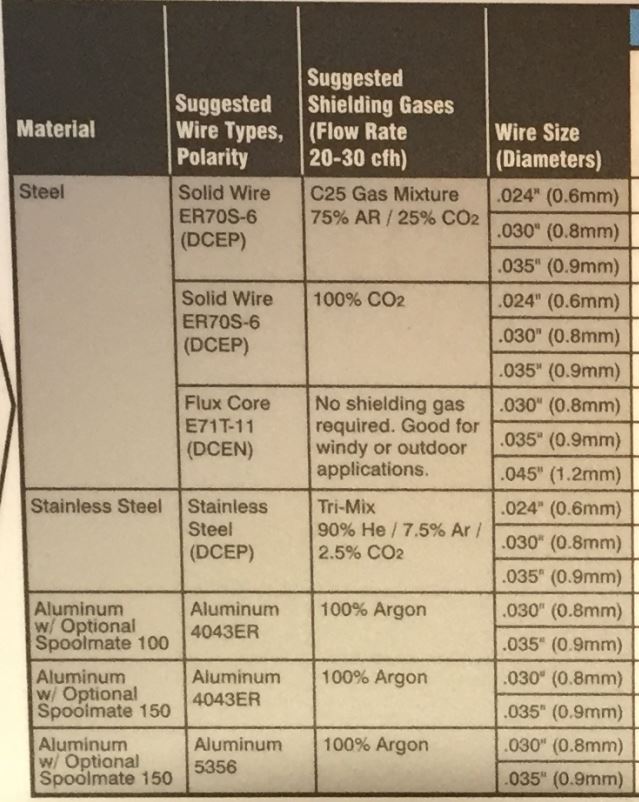

For aluminum 100 percent argon is the gas of choice. 90 helium 7 12 argon 2 12 carbon dioxide This will maintian the corrosion resistance of stainlees because its a mix. There are six noble gases but for the purposes of MIG welding only argon and helium are typically used.

In some cases there is tri-mix shielding gas containing 90 Helium 75 Argon and 25Carbon dioxide. Pure argon is the most popular shielding gas and is often used for both gas metal arc and gas tungsten arc welding of aluminum. There are basically two gases that are suitable for aluminum welding.

You should use 100 percent argon for aluminum. So which gases pair best with different base materials. Maybe a little harder to master.

Used also for aluminum and other non-ferrous metals especially for thicker welds. The Carbide MIG gas solution for stainless gage welds for weld shops that often were dealing with weld heat related issues was to promote and sell the worlds HOTTEST MIG gas Tri-mix. Helium improves thermal conductivity for short-circuiting transfer produces a flat bead profile and excellent sidewall fusion.

Its 11 ga which is 18 or 125 thick. A common tri-mix blend contains 90 per cent He 7-12 per cent Ar and 2-12 per cent CO 2. Again many welding supply stores carry their own mixture that can improve the weld quality and ease of welding on stainless steel.

Excellent welds are often produced using pure argon as a shielding gas. Stainless Steel MIG weld done with C2 gas. Blends of helium with the addition of 510 of argon and 25 of carbon dioxide tri-mix can be used for welding of stainless steel.

If you want to MIG all 3 your gonna need TRI-MIX ARGON and C-25 plus a spool of wire for each. Pure argon will give excellent results on all aluminum welding wether it be mig or tig. This is because argon in its pure form can be used on every type of base metal including for the notoriously finicky TIG welding aluminum.

Ad Find China Manufacturers Of Aluminum Welding. I just did it to show the difference in the amperage it takes to weld aluminum with pure argon versus adding helium. No I did not need to use a helium argon mix to weld it.

For most other MIG welding applications especially for steel 100 percent argon gas is. Not sure how heavy of stuff youre welding. Coupled with its high thermal conductivity using He will increase fluidity of the weld pool.

The Tri-mix containing 90 helium - 75 Argon - 25 CO2 requires the highest MIG weld voltages which for 60 years has ensured more energy into the thin MIG welds. MIG welding aluminum is different than welding steel when it comes to shielding gas requirements. If weld quality and appearance are important an argonCO 2 mixture can provide arc stability weld pool control and reduced spatter.

Welding of aluminum is typically done with Argon alone with one exception. These two gases can be mixed together to take advantage of their beneficial properties depending on the weld. Both gases are appropriate for MIG welding but argon is used more frequently.

The most popular MIG welding gas for stainless steel is a tri-mix or ternary blend of 90 Helium 75 Argon 25 CO 2. HELIUM TRI-MIX A RIDICULOUS GAS MIX CHOICE FOR SIXTY YEARS. If you are wanting to weld stainless steel carbon steel and aluminum why not just buy a TIG welder.

An argonHelium mix the most common being 25 helium is ideal for tig or mig welding aluminum over 14- 50 he for over 12 and 75 he for over 1 inch. Heliums high ionization potential promotes arc starting after the short circuit. Argon for example usually provides a stable arc but a wider and more shallow weld.

Effects Of Shielding Gases In Gmaw Welding Answers

What Gas Do You Use With A Mig Welder A Helpful Guide Welders Lab

Mig Welding Gases Choices And Options For Most Metals Gowelding Org

Mig Welding Gases Choices And Options For Most Metals Gowelding Org

Gas Types Used In Welding Mig Vs Tig Cromweld Com

What Is Mig Welding Gas Shielding Gas Basics Welditu

Welding Gas Available At All Kms Tools Locations

What Gas Is Used For Mig Welding A Complete Guide

Mig Welding Gases Choices And Options For Most Metals Gowelding Org

0 comments:

Post a Comment