General guidelines as Ive not done the specific weld you asked about. Ad Improve Your Business ROI - Get A Better Deal On Welding Rod.

What Is 4130 Chromoly And Heat Treating Heat Treating Steel Frame Seat Tube

I dont currently have a dual gage flow meter to back flow.

Welding 4130 to mild steel. To join the 4130 to the mild steel an. When a part design andor the application requirements do not require the weld deposit to match the strength of the 4130 steel it is possible to use a lower strength filler metal such as mild steel wire or stick electrode offering a tensile strength of approximately 70 ksi. 4130 to mild steel.

By Otto Nobedder Tue May 03 2016 130 am. I bet it spits sometimes. However the success of such a welding application will depend on the filler metal selected for the welding process and the welding.

Abrasion-resistant AR steel plate typically is more resistant to abrasive wear than steel or low-alloy steel plate so its often used in heavy equipment and mining equipment applications. Choosing the proper filler metal for 4130 and 4140 steels depends on the condition of the material. Welding A36 to AR Plate.

Generally it is recommended to weld 4130 in the annealed condition. If you decide to go that route there is no reason not to have the entire link ht. Pre-heat both the shaft and plate to 600-800 degrees F use stainless 300 series rod cover with insulation blanket or warm sand to slow cool.

The 4130 grade of chrome-moly is a high-strength low-alloy HSLA steel that contains molybdenum 015 - 025 percent by weight and chromium 08 - 11 percent by weight as strengthening agents. If a second pass is required interpass temperature should not exceed 400. You can successfully wield these two dissimilar metal together.

The filler metal recommended for welding 4140 steel is ER80S-D2. Know you cannot weld 4130 to mild steel. The oxweld does not have any good stuff like silicon to scavenge the junk.

Also what is the best type of filler rod to use when welding 4130 to 4130. Yes mild steel filler is fine for welding mild steel mounts to 4140 4130 tube Miller Syncrowave 200 WRadiator 1A water cooled torch Millermatic 252 on the wish list. The answer is yes.

New fabrication is typically performed on material in the annealed or normalized condition. With the elevated carbon content even low levels of hydrogen can wreck havoc. ER70S-2 can be used but you will be undermatching the base material.

Do I need to do anything differently when welding 4130 compared to mild steel. Can you weld dissimilar materials like stainless steel to mild steel. Welding 4130 chrome molly to mild steel tubing weldtek Materials 19 Aug 05 0822 As you probably know ER80S-D2 is commonly used for type 4130 material and it should work for your dissimilar joint too but you could probably use ER70S-2.

Select a filler metal. Plus of course if you do have an unfortunate accident it will shear the chome moly off the mild steel and be more useless than tinfoil. On 4130 tube is mild steel going to mixcontaminate with the chromoly and create excessive oxidizing issues chromium carbide on the back side like welding a mild steel plate to the end of a Chromoly tube.

The matching filler metal composition for the 4130 is covered by AMS specification 6457A. Pre-heat both the shaft and plate to 600-800 degrees F there is a special underlay rod to join the two dissimilar metals together. Is purging going to solve this or is that just delaying the inevitable.

When welding 4130 and 4140 steel holding the weldment at the preheat temperature for some time after welding followed by covering the weldment in ceramic insulation is beneficial because this allows the diffusion of hydrogen from the weld metal and the heat-affected zone HAZ. However the heat from welding will have an effect on the 4130 steel properties adjacent to the weld joint so you need to be specific regarding the base metal 4130 alloy steel strength requirements and the limitation associated with the dissimilar metal weld joint strength. 4130 being an HTLA steel product form has high hardenability and is susceptible to hydrogen cracking in the weld metal and HAZ.

Im thinking of welding some 4130 steel Ive not welded anything other than mild steel so far. Its not recommended to weld 4130 or 4140 steel in the quench and tempered or case-hardened conditions without first performing annealing or normalizing in the area to be welded. And btw I would use this for all your chromoly welds.

However it has relatively low carbon content nominally 030 percent so it welds machines and bends almost as easily as 1018 DOM mild steel tubing which has an 018 percent carbon content. I would use E70S-2 mild steel tig welding rods. You can weld mild steel inserts to ht 4130 tubing but you will be tempering back the ends next to the weld and the hardness of your link will be all over the place.

Sticking with 4130 or mild steel for the brackets welding them with 70s-2 filler and tempering the weldment would be my suggestion and that. Mild steel filler metals offer the advantage of additional crack resistance due to their ductility but the resulting weld. The main reason is that when you mig 4130 it superheats it and cools too fast and you get micro cracks that will get detected in the inspection process.

ER-80S is compatible with mild steel and is not normally post weld heat treated so you must make your decision on what filler metal you should use to join the HTLA to mild steel while taking into consideration the metallurgical characteristics of both. Low-hydrogen electrodes minimize the amount of diffusible hydrogen in the weld. With E70S-2 the welds will be a tiny bit stronger than the mild steel but.

While I feel this is a total bullshit way to do it to each his own. Most high-chrome steels are pre-heated to 350-375. Ad Improve Your Business ROI - Get A Better Deal On Welding Rod.

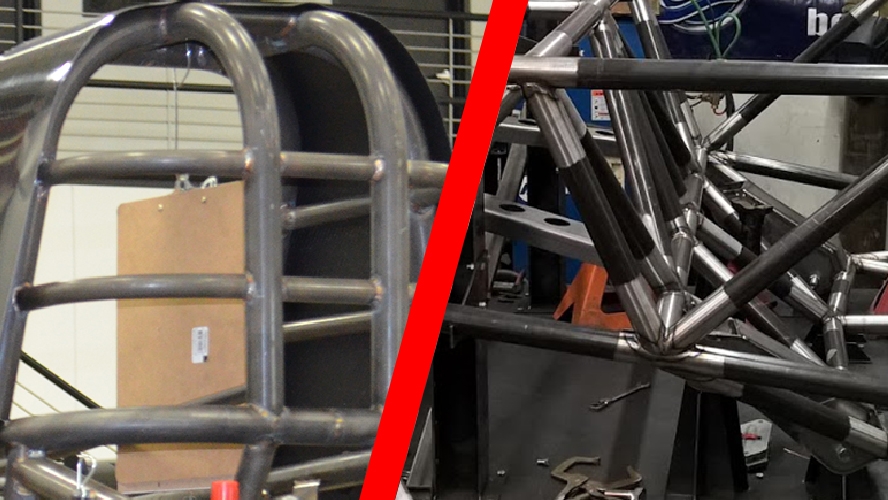

Mig Welding Mild Steel Roll Cages 30 45 And 90 Degree Angles Mig Welding Welding Welding Technology

In How To Weld Chrome Moly Part 2 Mr Tig Addresses Some Key Issues Asked About 4130 Including Filler Materials Cooli Welding Videos Metal Working Welding

What Are The Best Preparation Practices For Welding 4130 Chrome Moly A E D Metal Products Supplies

A Beginners Guide To Welding Chromoly Beginner Welding Guide

Tig Welding 4130 Chromoly Tubing Youtube

1 25 Rod End Set 1 5 Tube Id Race Car Parts Jeepster Rod

Sheet Metal Punch Flare Tool Dimple Die Business Office Industrial Metalworking Milling List Metalla Izgotovlenie Metallokonstrukcij Metalloobrabotka

Astm A283 Grade C Equivalent Structural Steel S235 S275 S355 Ss400 A36 S235jr S355 St52 A573 A283 Steel Plates Angle S235jr S355 Steel Plate Steel Carbon Steel

Welding Question Welding 4130 Steel To Other Metal

0 comments:

Post a Comment