8620 is a low nickel - chromium - molybdenum medium hardenability case hardening carburizing steel generally supplied in the as rolled condition with a maximum brinell hardness of 280 Rc30Characterised by good core strength and toughness in small to medium sections with case hardness up to Rc62 when carburized hardened and tempered8620 can also be used uncarburised. Many options exist within the world of low carbon steels.

With the elevated carbon content even low levels of hydrogen can wreck havoc.

Welding 8620 to mild steel. If you are welding the 8620 to 1018 your filler metal only needs to match the strength of the 1018- 70 series consumables would be acceptable. Cast Iron to Mild Steel Welding From PWL025 Section 3 Q. Although all of the above can be used on mild steel you must make your selection based on the application.

Welding Filler Metal Designators. Welding 8620 Steel Bar. By GRoberts Date 05-06-2008 1714.

No cracks after 1 year. The repaired shafts ran 1 year without problem then we replaced them. AISI 8620 Steel is a low alloy nickel chromium molybdenum case hardening steel.

The alloy may be welded by conventional methods usually gas or arc welding. For stick welding a specialty stainless steel electrode for hard to weld crack sensitive steels such as a modified 312 type eg. The CNCd teeth would help a lot and reduce the heat input requirement due to welding only holding parts lined up.

The 8620 is weldable. When a higher-strength part is welded to a lower-strength carbon steel the filler metal. Another choice of weld rod would be AWS 55 E10018M for the AISI Type 8620 base metal.

I thought all tool steel should be pre-heated. Preheating at 400 F is beneficial and subsequent heating after welding is recommended consult the approved weld procedure for the method used. On single-pass fillet welds tests have shown that diluting the weld and base material will produce an adequate strength.

Hopefully an engineer or metallurgist can correct any errors I may post. TYPICAL WELDING PROCEDURE The procedure that follows are those that should be used when repairing most The following procedures should be utilized for the repair of AISISAE 8620 TOOL STEEL. At any rate if you are tigging 8620 oxweld or ER 70S-2 would work well for this low carbon steel.

Other elements may be added for special purposes. As others noted you can weld 8620 round bar to A36 mild steel plate if you use the proper filler wire preheat etc. If the welded component will be used in the as-welded or stress-relieved condition select a low-hydrogen-type electrode with a tensile strength of about 110000 PSI.

Designates an Electrode Designates minimum tensile strength in Ksi of the as-deposited weld metal E XX YY 1 HZ R Designates the welding position the type of covering and the type of welding. - Cast Iron is an alloy of iron carbon and silicon. Ive also been told that this may have had a oil quench and thus does not require a pre-heatpost heat process.

Literature says 8620 welds easier. Forming characteristics of 8620 alloy are good in the annealed condition. Gray Cast Iron is probably the most common type.

Lincoln Electrics Blue Max 2100 may be your best choice. - How should one weld Cast Iron to Mild Steel. Why dont you consider designing your part to use a bolted connection between the.

Shouldnt be much stress on the weld. Preheat is required and PWHT is. 6011 or 7024 sticks work ok for this.

PWHT with electric pads 1100 F 2 hours slow heatup cooldown. But it would not be practical to heat treat the 8620 material after welding. Visually inspect the tool or die to determine the reason for failure and establish.

Maybe you will be lucky and find. It has a very high tolerance to free machining steels or steels with a low manganese to sulfur ratio ie. AISI 8620 Steel 16523 21NiCrMo2 SNCM220 - Otai Special Steel.

Rods suggested so far have included 312 SS and Eutectic 680S and 9018. . Qualify the base metal composition if possible.

The chemical composition of the AISI Type 8620 compares with AWS 55 E8010-P1 weld rod which is used for pipelines. Types of Low Carbon Steel For Common Applications. Low carbon mild steel is the industry standard for room-temperature welding work.

E11018-M stick rod stringers only 12 max bead width. The higher the carbon content the more difficult the steel is to weld. My design calls for me to make the header out of 125 round about 14 thick then welded to a short mild steel handle.

ER70S-2 can be used but you will be undermatching the base material. The keyways had fractured. In some cases a specification will allow or require a lower-strength filler material.

Ive repaired 5 4140 boiler grate drive shafts welded to large 8620 couplings. We supply Schlumberger good quality sae 8620. However you need to determine the heat treatment condition of the AISI Type 8620 base metal before final selection of a weld filler metal.

For the curious the nail header is made by doming the end of a rod of the alloy steel with a. With slow cooling its excess carbon solidifies as flakes of graphite. Low-hydrogen electrodes minimize the amount of diffusible hydrogen in the weld.

Pre-heat to 400F use a low-hydrogen rod to match material tensile strength E9018-M H4R E11018M H4R and post heat for stress relief. I have been researching all week and many suggested 400 F for pre-heat with slow post weld cooling. I was reading this material is carburized for this application.

75 Argon 25 Carbon Dioxide 7525 90 Argon 10 Carbon Dioxide 9010 95 Argon 5 Oxygen 955 And many other mixtures. Preheat 600 F. For example you can weld mild steel with any of the following shielding gases.

The most common types of mild steel AISI 1010 1018 and 1020 all contain trace amounts of carbon and are ideal for welding. The filler metal recommended for welding 4140 steel is ER80S-D2.

How To Really Sharpen Tungsten For Precision Stainless Tig Welding No T Tig Welding Types Of Welding Welding And Fabrication

How To Weld 4140 Steel Welding Answers

Welding Hardened 8620 Miller Welding Discussion Forums

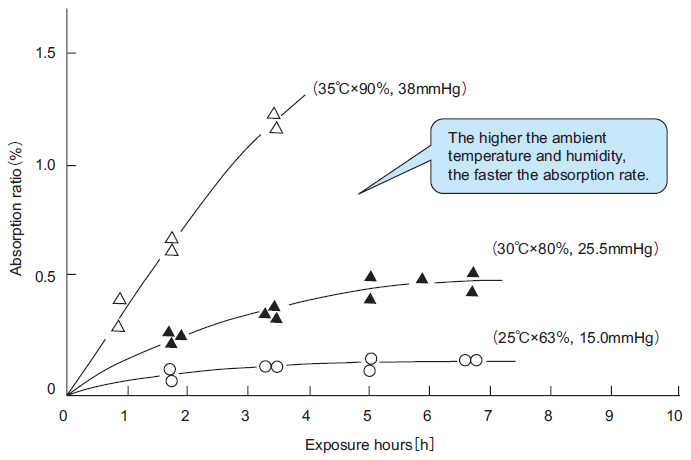

Welding Of Medium High Carbon Steels And Special Steels Education Center Kobelco Kobe Steel Ltd

Awesome Tig Welding Welding Metal Welding

The Prettiest Mig Weld I Ever Managed To Do On Galvanized Steel Welding And Fabrication Metal Shop Building Metal Welding

Handbook Of Mould Tool And Die Repair Welding Semantic Scholar

Recommendations For Welding T 1 Steels Welding Answers

0 comments:

Post a Comment