Features like hot start make it easier to ignite an arc at or below the electrodes recommended amperage. The welding rod should be in a vertical direction.

How To Weld Gray Cast Iron Cast Iron Welding Guidance

Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding.

Welding cast iron with arc. Ad Improve Your Business ROI - Get A Better Deal On Arc Welding Rods. Its simple and there is a wide range of electrodes available to suit different jobs with many arc welders available for both commercial and domestic purposes at reasonable prices. If youre welding up a machined surface the best option would be to TIG weld it.

Limit weld quantity in one run. Gas Welding is also a slow. The disadvantage of MMA is the greater weld pool penetration and parent metal dilution but using electrode negative polarity.

Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding. Because we start with spot welding about 20 A should be ok for a 116 electrode rod. A critical temperature in most cast iron is about 1450 degrees F.

See this video for detailed directions. Cast Iron Welding Methods. MIG requires an Argon gas mixture 80 argon 20 carbon dioxide and a nickel wire.

Ad Improve Your Business ROI - Get A Better Deal On Arc Welding Rods. This means Carbon migration is not normally a problem. The Arc Welding of Specific Steels and Cast Irons is to provide information to assist welding personnel study the arc welding technologies applied in specific steels and cast irons.

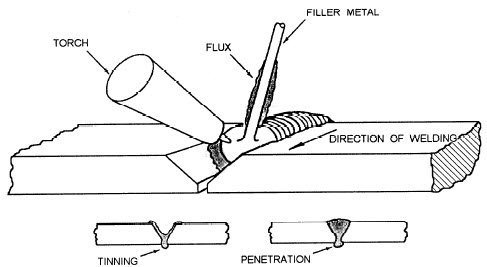

Run a bead across each part of the crack. Like MIG use a nickel wire. Use of a proprietary Cast iron Gas Welding rod is important.

While the arc will heat the casting to temperatures above this level it is important that the casting not be held at this temperature for long periods of time. Cast iron needs to be preheated before welding. TIG welding shouldnt give you any spatter issues.

However you might have to play a bit with the settings depending on your welding plants capabilities. Stick welding is one of the most common and dominating welding processes to weld cast iron. Arc Welding Cast Iron Arc or stick welding is often the preferred method for many DIY welders.

MMA widely used in the fabrication and repair of cast iron because the intense high temperature arc enables higher welding speeds and lower preheat levels. No representation or warranty is made as to. While all three methods can be used we recommend Arc for home welding.

Process for Welding Cast Iron. Use the appropriate rod type. When at this temperature conditions that can lead to cracking occur.

Its a form of arc welding. Arc TIG or MIG. You can use stick welding for effective joints and its very economical.

The only real downsides to Gas Welding Cast Iron is the amount of heat needed if components are large. Gas Welding heats the Cast Iron slower than Arc based processes and the flame is lower temperature than an arc. Ensures a little preheat at room temperature.

Prepare the job with a groove in U. Oxy-acetylene welding is another option frequently used to weld cast iron. The spatter from MIG or stick welding may unnecessarily damage parts of the machined surface not being welded.

The best all-round method for Welding Cast Iron is arc welding. Reasonable care is taken in the compilation and publication of this textbook to insure authenticity of the contents.

Cast Iron Welding Procedure Step By Step Guide Cruxweld

How To Weld Cast Iron Metal Casting Blog

Stick Welding Cast Iron Repair Using 7018 Welding Rods Youtube

Stick Welding Cast Iron Repair With Muggy Weld Youtube

Welda Day 5 Weld Repairing Cast Iron With Cast Iron Filler Rods Youtube

0 comments:

Post a Comment