If rails with 880 Nmm² minimum tensile strength are installed then the rails should be warmed before the start of flame cutting. While welding a steel by using neutral flame the molten metal flows flawlessly without foaming sparking or boiling and the metal puddle is quiet and clear without any chemical reaction.

Hazards In Welding And Cutting Industrial Health Safety Review

During the condensation period the metal forms dust particles so small that they can be breathed deeply into the lungs.

Welding cutting flame. Ad Quality Sale Welding Machine with Competitive Price. A flame is called a 2X flame if the inner core is half of the acetylene feather. The rail should be warmed over a length of.

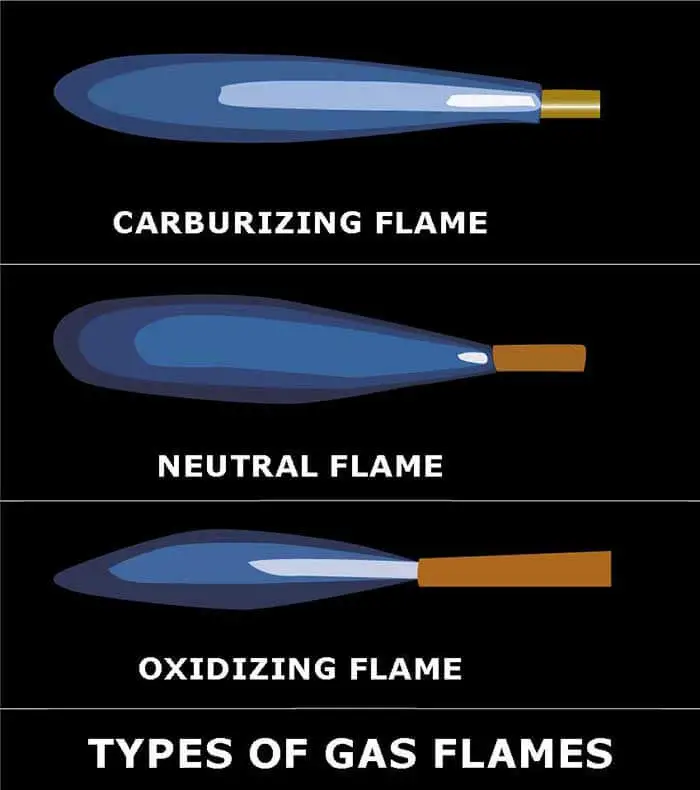

It is just a way of expressing the carbon content in the flame and is an indication of the degree of flame carburization. There are three types of flames natural flame carburizing flame. This flame adjustment is used for most weld operations for preheating during cutting operations.

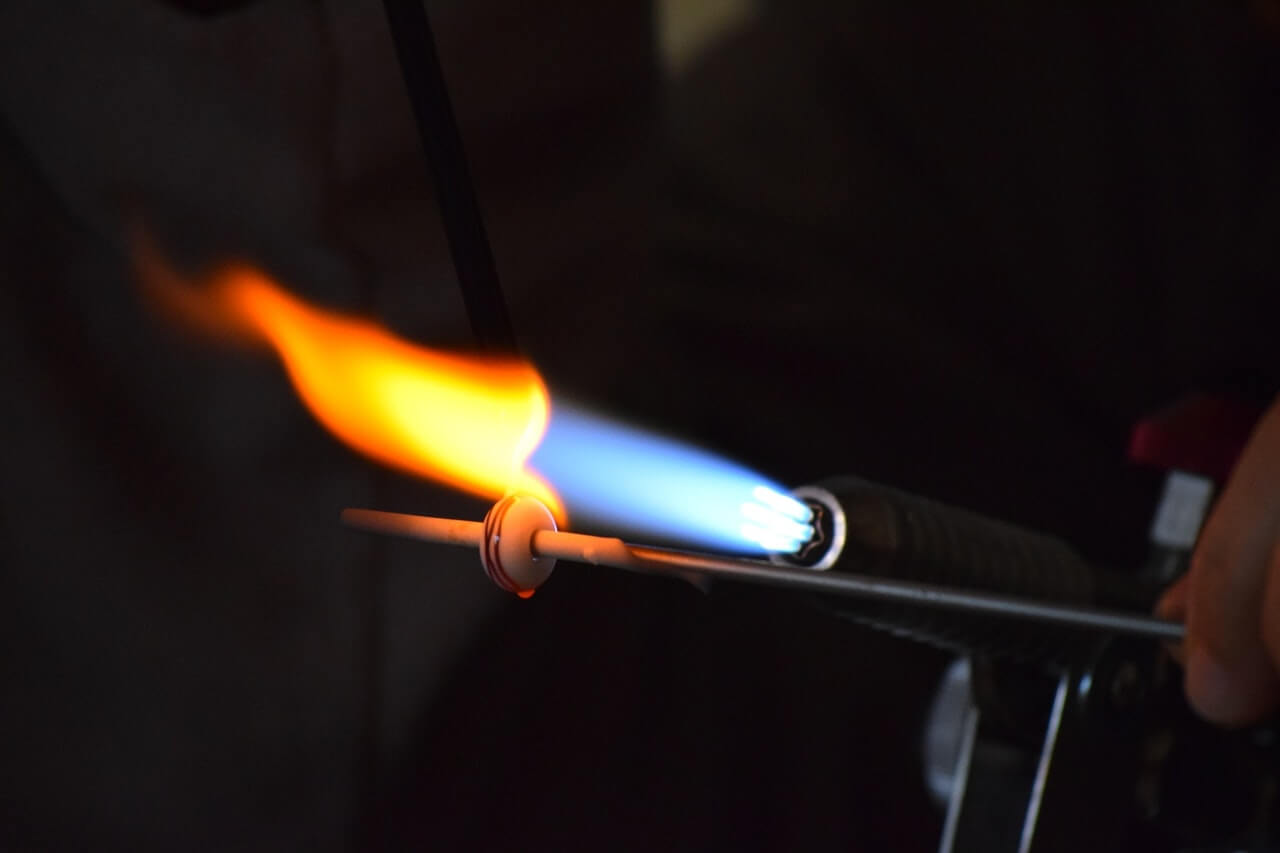

It is affected by the chemical reaction of oxygen with the base metal at elevated temperatures. The molten metal puddle is cold and clean when welding with this flame. It is carried out using a torch through which oxygen and a fuel gas acetylene propane or mains gas are passed.

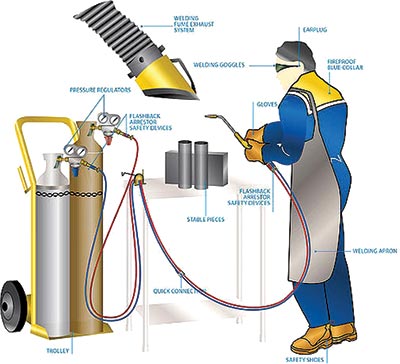

The neutral flame burns cleanly and is used for most welding applications. Equipment 5 Typical components of the equipment used in gas welding. Health factors when welding and flame cutting When a metals temperature is raised above melting point it starts to condense in the air.

Oxidizing flames are the hottest and least used due to the oxidation of the base material. This Procedure provides safety and health instructions regarding gas and electric welding cutting brazing or similar flame or spark-producing operations to protect personnel and property against heat evolved gases and fumes electrical shock and radiation. The three basic flames used for gas welding include neutral carburizing and oxidizing.

The metals flow easily without boiling foaming or sparking. China Sale Welding Machine. The flame is hot enough to fuse the metal surfaces together for welding whereas in the case of cutting hot enough for the formation of molten oxides of the metal concerned.

The process is now about 111-112 years old as it was patented in 1901 by Thomas Fletcher. Flame cutting also known as torch or oxygen-gas cutting is a chemical reaction between pure oxygen and steel to form iron oxide. In order to weld low carbon steel you can use a carburizing flame to produce the welding.

An outer ring of jets in the torch nozzle are used to preheat the surface of the steel. Theweldings - November 26 2020. 121 In this COP gas welding and flame cutting refer to a welding or cutting operation with a flame produced by mixing a fuel gas and an oxidant gas in a blowpipe.

As we have discussed earlier Flame cutting is a process of Oxygen cutting and. In flame cutting the flame heats the workpiece to a temperature at which the metal oxide can be formed from an additional supply of oxygen at the blowpipe. We use natural flame for almost every welding operation and for pre heating in cutting procedures.

It is rapid controlled rusting. In welding these metals the oxidising flame produces a base metal oxide layer to protect the evaporation of low melting point alloying elements. Applications of Carburizing Flame.

China Sale Welding Machine. The oxide is melted and blown away by the force of the flame. The flame cut can be done with a flame cutting gauge thus a 90 cut to the rail is possible.

Carbonizing flames are cooler and often used when working with steel or iron. An oxidising flame is used for welding copper base alloys zinc base alloys and a few of the ferrous metals such as manganese-steel and some of the cast irons. The process often called Flame Cutting is known by many names such as Oxy Acetylene Cutting Oxy Fuel Gas Cutting Oxygen Burning Steel Burning and other terms too numerous to mention.

The flame plays lead role to create weld joint and the weld properties are highly depended on it. Flame cutting types and process. Only low-carbon steel and some.

Also known as oxy-fuel cutting the process is used for separating and shaping steel components. In this welding process gases fuels are burn and produce high temperature flames which further used to create weld joint. Ad Quality Sale Welding Machine with Competitive Price.

For The Beginner Plasma Cutter Or Oxy Acetylene Torch Beginner Welding Guide

4 Types Of Welding Processes Weld Guru

Tool School Break Out The Torch

Lpg Apps Lpg Offers Wide And Diverse Uses In Varying Fields

Who Will Need The Oxy Fuel Welding And Cutting News Morris Precision Techno

A Detailed Guide To Oxy Fuel Oxyacetylene Welding Workshop Insider

Oxy Fuel Welding And Cutting Wikiwand

Oxy Fuel Welding And Cutting Wikiwand

Complete Guide In Types Of Welding Flames Facts Applications Metalworkmasters Com

0 comments:

Post a Comment