Flexible ducting allows the capture hood to be moved where required. Upon a final understanding of the exhaust volume the contaminants being collected and the velocity requirements sizing the ductwork for an industrial ventilation system can be determined with the Flow Rate Equation QVA.

Hvac Air Handling Unit Http Techshoreinspections Blogspot Com 2016 12 Techshore Inspection Services Hvac Air Handling Unit Hvac Services The Unit Hvac Air

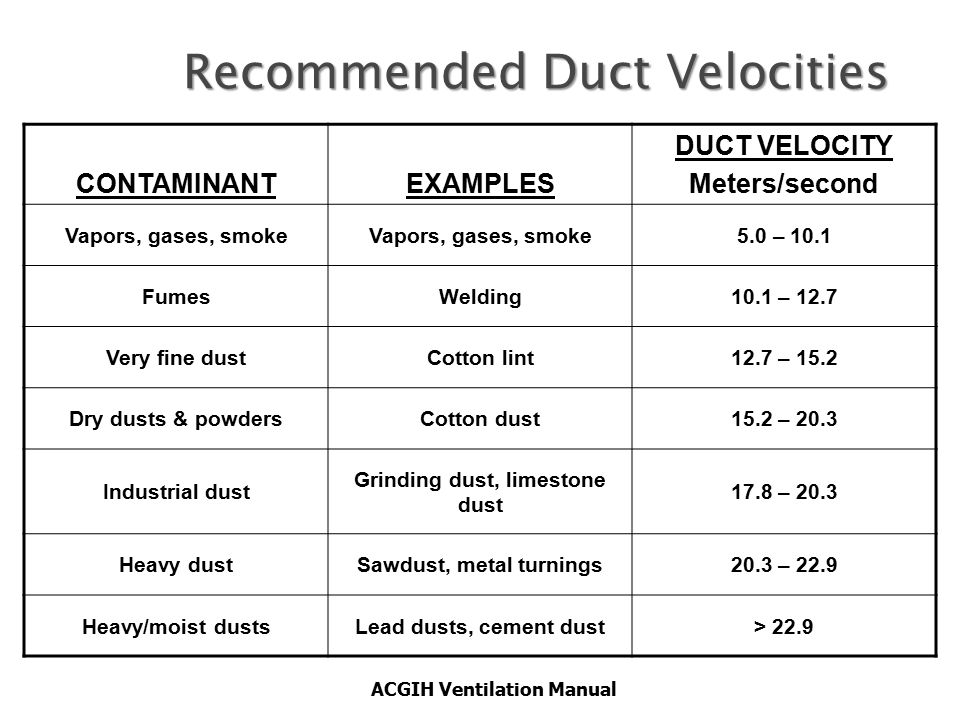

Duct velocity 2000 to 3400 fpm.

Welding exhaust duct velocity. How big should the slot be. The duct velocity in a welding fume removal system should be 2500 to 4500 fpm and a face velocity at the receptor of 1500 fpm. Example - Capturing air velocity for a smaller exhaust outlet Capturing air velocity in distance 250 mm from a 250 mm duct with internal air velocity of 3 ms can be calculated as vc 3 ms π 0250 m2 48 0250 m2 02 ms.

Duct Pressures P T P S P V ie. The need for special filtration or a direct exhaust duct route to the outside with U-M OSEH. Filtration and direct exhaust are not typically required.

Maximum hood slot velocity 3000 fpm. Place the hood as close as practical to the work. The optimal location for the hood is about 1 duct diameter from the arc.

LEV is an engineering system designed to reduce employee exposure to airborne contaminants dust mist fume vapour gas in the workplace by capturing the emission at source and transporting it. Exhaust ventilation LEV is one such engineering control measure. For some applications where steel such as galvanized with a toxic fume emitted is.

The say an ounce of prevention is worth a pound of cure. Is the exhaust air volume from the hood at least SEE NOTES BELOW. Maximum hood plenum velocity 2000 fpm.

Construct a hood to cover the entire 10x10 welding area but put a plate in the bottom of the hood so that most of the opening in blanked off. As an example lead dust which is relatively heavy typically requires a minimum conveying velocity of 4500 feet per minute whereas weld fume which is much lighter may require 2000. Hoods generally remove the fumes and contaminated air through ducting and exhaust the contaminants to the outdoors.

You will have to weld straps or come up with a way to support the plate. Is the duct velocity 2500-3000 fpm IV Manual. Q t 125C f 10x 2 A where C f 075 for flanged or tapered duct C f 10 for plain duct 125 capture velocity of 125 fpm A face area of duct.

Both stationary and mobile local exhaust ventilation systems exist and they consist of a capture hood duct system air-cleaning device fan and outlet discharge ductwork 64. Provide an air velocity of at least 100 ftmin 05 ms across the welding arc. From the weld rod tip to the hood the rate of exhaust should be 600 cfm minimum.

Entry loss 178 VP plus duct entry loss. Or greater multiple take-offs are desirable. IVIs engineering and design team has years of experience designing and sizing industrial ductwork.

In all cases. Table 1 - Weld Fume Ratios. Ducts are commonly classified as Low Velocity Systems - with air velocities up to 2000 fpm 10 ms Medium Velocity Systems - with air velocities in the range 2000 to 2500 fpm 10 - 13 ms High Velocity Systems - with air velocities greater than 2500 fpm 13 ms.

The table below shows weld fumes generation ratios for the various welding methods. Or greater multiple take-offs are necessary. Is a moveable exhaust hood provided.

Hood lengths 10 ft. This information can be used to determine the amount of fume being generated and consequently the air velocity needed to adequately capture those fumes15. Hood lengths 6 ft.

This will leave you with just a perimeter slot around the 10x10 welding area. IVI can assist in the design of a new system or. A statement of an energy balance Static pressure potential energy term Velocity pressure Kinetic Energy term Total pressure total energy term 2Recall KE is ½ mV so KE term is proportional to V2 P s P v.

Is dependant on the type of welding being performed and the type of metal being welded. Volume Velocity X Area. Reduced Face Velocity fume hoods incorporate an air foil mounted above the hoods working surface.

U-M spec section 115313 requires that the sash stop location be adjusted. Such as duct heaters dampers filters grilles coils etc Calculated by the following formula derived from Bernoullis P TOTAL K T X P V 2 K T X ½ X ρV P TOTAL the total pressure loss across the duct fitting K T the pressure loss coefficient of duct fitting P v velocity. Taking the time to identify and implement your ideal kind of welding exhaust ducts can be your welding systems ounce of prevention.

Hoods should be placed as near as practical to the work and should provide effective air flow with a velocity of 100 linear feet 30 meters per minute at its most remote distance from the point of welding. Local exhaust ventilation systems need to remove the welding contaminants without disturbing the welding process eg the fume-capture velocity at the weld zone must.

Unico Micro Duct Air Conditioning Systems Unico Air Conditioner Unique Indoor Co High Velocity Air Conditioning Heating And Air Conditioning My Home Design

Half Cell Electrical Potential Method Http Techshoreinspections Blogspot Com 2017 02 Half Cell Electrical Potential Method Html Cell Electricity Oil And Gas

Pin By Apinut S On Air Con System Room Doors Mechanical Engineering Home

4 Inline Duct Exhaust Fan Air Blower Hydroponics Cooling Vent Ho 2890rpm 160cfm 4 High Velocity Inline Blower Powerf Exhaust Fan Inline Fan Air Ventilation

Direct Drive 6500 Cfm Confined Space Ventilator Free Shipping Confined Space Combo Kit Portable Ventilation Fan

Maxxair Hvhf 12combo Heavy Duty 12inch Cylinder Fan With 20foot Vinyl Hose Yellow See This Great Product Hose Floor Fans Air Tools

Classifications Of Air Conditioning Systems Http Techshoreinspections Blogspot Com 2016 12 Techshore Ins Air Conditioning System Conditioner Air Conditioning

General And Local Exhaust Ventilation Ppt Video Online Download

From The Motor Side To Look The Centrifugal Blower Www Lxrfan Com Xrblower Gmail Com 1 If The Centrifugal F Centrifugal Fan Blowers Air Conditioning System

0 comments:

Post a Comment