Low hydrogen welding electrodes such as E7015 E7018 E8018 E9018 and E308-16 shall be purchased in vacuum-. Ad We supply Inconel 625 600 825 welding electrode filler wire.

Welding Inspection Checklist Inspection Checklist Welding Welding Inspector

White Papers Engineering Documents and Specifications Weld Design and Engineering.

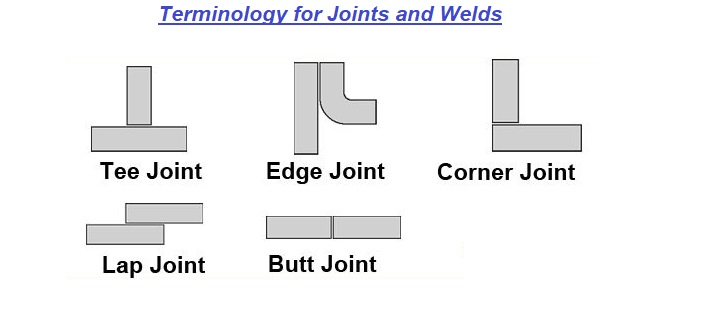

Welding guidelines for design engineers. This resource requires a Premium Membership. Procedures for review of technical. Butt Weld Section Modulus Equation and Calculation.

Wire feed speed sets the welding current. These General Welding Guidelines are intended to provide. Contact our experts now.

Shielded Metal Arc Welding SMAW Gas Metal Arc Welding GMAW Gas Tungston Arc Welding GTAW. Welding quality assessments by TWIs welding engineers may include a review of your companys manufacturing process namely. Electrodes and Filler Metals.

Contact our experts now. Static Strength of Welds FFNormal Shear F w h F w h 2F F F 18 75o 38 14 Max Normal Max Shear F 0618w h F 0707w h Butt Fillet h throat size. The overview of the joining processes featured in.

The more welding done the more distortion will occur. DESIGN GUIDE 21 WELDED CONNECTIONSA PRIMER FOR ENGINEERS vii 44 WELDING REQUIREMENTS FOR SPECIFIC STEELS 60 441 Weathering Steels 60 442 Quenched and Tempered Steels 61 443 Historical Obsolete Steels 62. Fatigue Weld Design Based on S-N Data.

When designing products that require welding the designer should consider very early on in the project the implications of the choice of welding process and how the component will be made. Welding Power Sources. They were designed for engineers to do preliminary designs and process specification sheets.

Fillet Weld Moment of Inertia Equations and Calculation. Fundamentals of Arc Welding. Number of components being fabricated.

These requirements have led to a number of developments notably the publication of ISO 3834. Welding Basics for Designers and Engineers. Fillet welds shall be made so that they penetrate fully into the root.

Throat Size 18 75o 38 h plate thickness weld size Butt h 0707 plate thickness 0707 weld size 14 Fillet. Fillet weld termina-tions may extend to the ends or sides of parts or may be stopped short or may be boxed except as limited by 2472 through 2475. Proper joint design and correct welding procedures limit distortion.

We Offer Specialized Welding Solutions in Inconel Monel Incoloy. Welding Basics for Designers and Engineers. Inductance in Dip Transfer stabilises the arc and minimises spatter.

Certain welding configurations are more likely to distort. Demands of the welding position. ENGINEERING DESIGN GUIDELINES Page 5 of 98 Rev.

Voltage controls the profile of the weld. Even if the design is appropriate however defects produced during welding will have a major influence on quality. Ad We supply Inconel 625 600 825 welding electrode filler wire.

Fillet Weld Polar Moment of Inertia Equations and Calculation. Welding can largely be described as a special process and the choice of welding process for a particular job can be difficult without expert knowledge. Minimum Fillet Weld Size per AWS D11 Table.

Fixturing use of heat sinks see Figure 2 and special welding techniques. For example welding four corners on a cover or enclosure usually produces distortion. Availability of suitable welding consumables.

01 June 2020 These design guideline are believed to be as accurate as possible but are very general and not for specific design cases. The table gives a guide to the selection of wire diameter but the exact relationship depends on the material and the shielding gas. The information and guidelines are provided to the welder solely for his.

In the field of weldment design1the primary objectives are to produce an assembly that 1 performs its intended func- tions 2 has the required reliability and safety and 3 can be fabricated inspected transported and placed in service at a minimum total cost. The information and guidelines in this Welding Handbook are based on general information and knowledge at hand and are believed to be accurate and reliable but the information and guidelines are not to be taken as a guarantee or warranty for a special purpose. Welding defects and strength quality In order to prevent welding defects and improve quality it is important to select materials and processes suitable for the application in the welding design phase.

Welds including end returns or boxing shall be indicated on the design and detail drawings. In lap joints between parts. We Offer Specialized Welding Solutions in Inconel Monel Incoloy.

Cost of the process including capital expendi-tures materials and labor. Butt Weld Throat Area Equation and Calculation. Voltage high correct low 75 0 - 80 0 450 - 550 Current Wire feed.

International Welding Engineer Certifications Welding Welding Certification Welding Inspector

Welding Joint Design Important Considerations Safe Work Method Of Statement

Following Dfm Guidelines For Working With Sheet Metal Sheet Metal Sheet Metal

Pin On 2017 Cad Tips Tricks Articles

Pin By Susan Urbaniak On Michael S Mechanical Engineering Design Geometric Tolerancing Mechanical Design

Design For Welding Letter To An Engineer

Different Types Of Welding Defects Types Of Welding What Is Welding Welding

Get Our Sample Of Energy Audit Report Template Report Template Energy Audit Audit

Handbook Of Machining And Metal Working Calculations Pdf Free Pdf Books Mechanical Engineering Metal Working Engineering Projects

0 comments:

Post a Comment