The composite insert consists of a transition joint between dissimilar metals made by a welding process that does not involve heating. Welding is usually used on metals and thermoplastics but can also be used on wood.

Types Of Welding Joints Welder Portal

Welders usually work with metal or thermoplastic and use permanent filler material to bond them together.

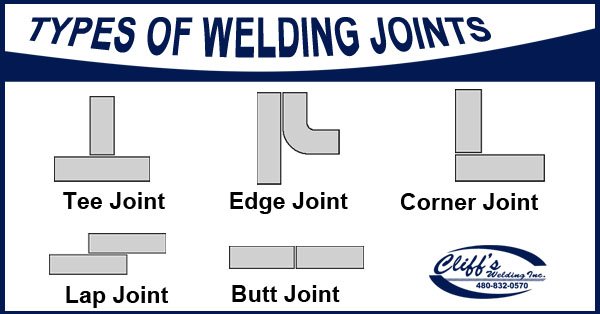

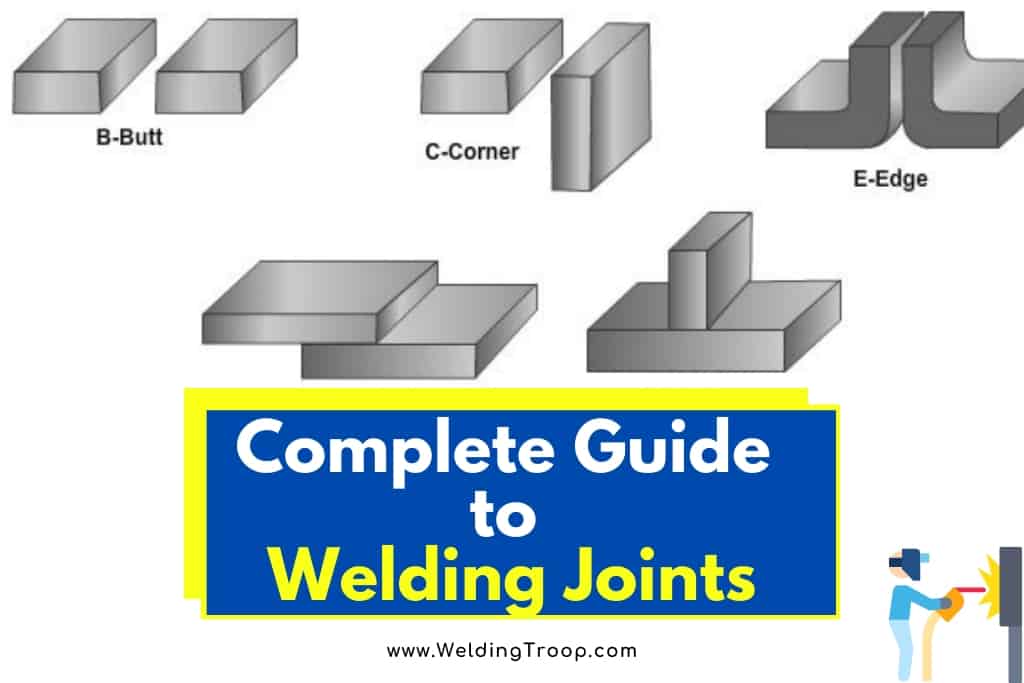

Welding joint for joining two metal is. It is possible to join metal pieces by methods like riveting soldering bolting or brazing. These are common in the construction of boxes box frames and similar fabrications. There are many reasons for which you might need to join pieces of metal together.

The joint is formed when the two pieces of metal are placed on top of each other in an overlapping pattern. Welding is used to creating many modern constructions in our world such as skyscrapers cars ships and planes. However there are several alternatives to welding methods that can be used to do this.

The completed welded joint may be referred to as a weldment. Welding is done by application of heat or both heat and. Welding is a process of permanently joining materials.

Being one of the most popular welds in the sheet metal industry the Corner welding joint is used on the outer edge of the piece. I personally find it the easiest joint to weld. This type of joint is used to join two pieces of metal together with different thicknesses.

The term lap joint is coined from the end of the word overlap The two overlapping plates are described by the shortened term lap joint What to know when welding lap joints. You then weld along one or both edges according to how strong you would like the joint. Welding is a fabrication process whereby two or more parts are fused together by means of heat pressure or both forming a join as the parts cool.

This weld is a type of joint that comes together at right angles between two metal parts to form an L. Welding joins different metalsalloys with a number of processes in which heat is supplied either electrically or by means of a torch. Another method of joining dissimilar metals is the use of a composite insert between the two metals at the weld joint.

This is often the most reliable welding joint due to the large surface area between the welds. Soldering brazing and riveting. The basic purpose of welding is to join two elements with a permanent joint.

Lap weld joint. To perform a fillet weld we change the way we position our welding torch against the material so that we penetrate into the corner of our joint at. In the past builders used other methods of joining metal workpieces.

Fillet welding refers to the process of joining two pieces of metal together whether they be perpendicular or at an angle. One of the most common methods of joining two pieces of metals together is through welding.

Mechanical Engineering Design Of Welding Joints

Welded Joints Using Oxy Acetylene Torch

What Are Welding Joints This Is The Process Of Two Pieces Of Metal Or Plastic Joining Together At A Point Or Edge Depending On The Shape Of The Metals And According To

5 Types Of Welding Joints Cliff S Welding Mesa Az 480 832 0570

5 Types Of Welding Joints And Their Use 2020 Complete Guide

5 Types Of Welding Joints And Their Use 2020 Complete Guide

0 comments:

Post a Comment