You should therefore remove the oil from the steel before welding. Use Acetone On Your Filler Metal Rods It is not always obvious that the aluminum stainless steel metal filler rods for TIG welding have a layer of oil on them too.

What Causes Welding Spatter And How Do You Reduce It By Jacob Mills Medium

Dirty rusted oily or otherwise contaminated metal wont hold a weld.

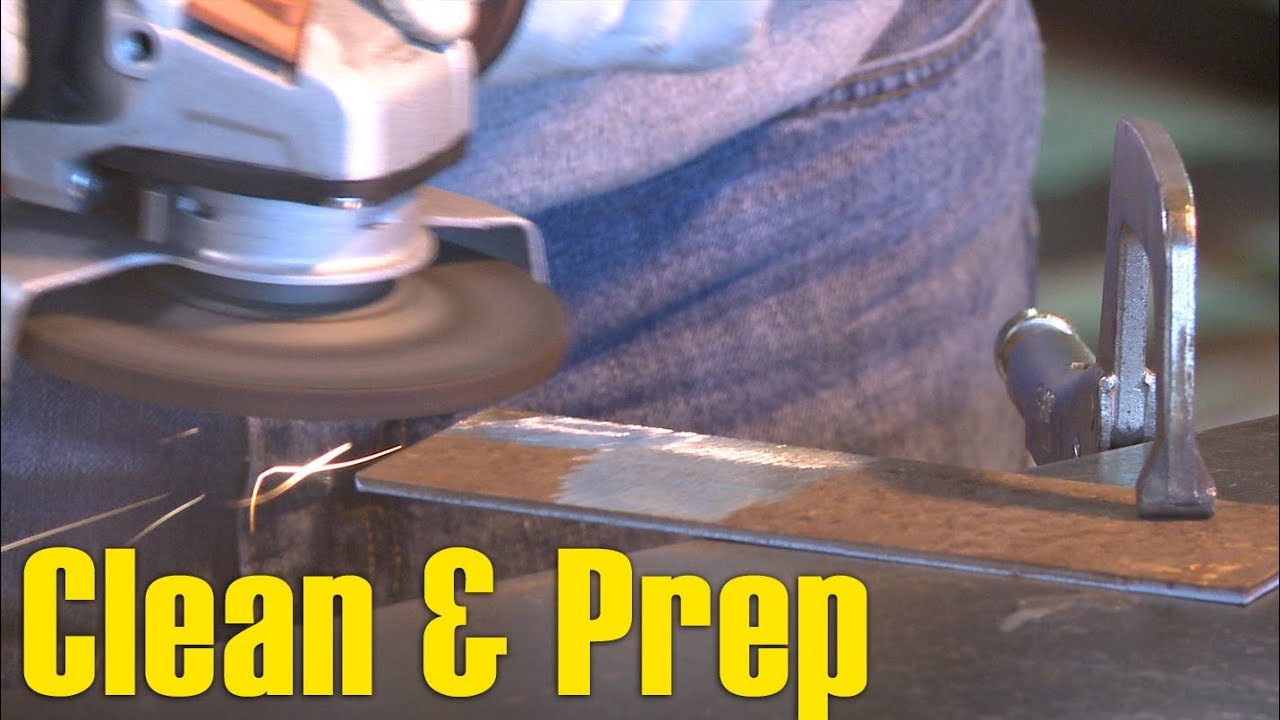

Welding oily metal. Unlike cement glues this oily glue is going to give you a soft and strong bond on everything you do. To combat rust oil and dirt in MIG welding you will need the input of a grinder and metal brush to clean out your metal surfaces before you can create an arc. It is EASY to USE a REALLY MUST HAVE to your DIY TOOLBOXES.

Its waterproof and shockproof feature makes the repair durable and guaranteed not to wear off. Why spending on replacements when you can repair them with the Welding High-Strength Oily Glue that can give them back to you as good as new. In case of higher material thicknesses you should preheat the part before welding to slow down the cooling time.

Some electrodes will weld in all positions. 1x Welding High-strength Oily Glue. The amount of reinforcement needed may require more than one pass.

These are all surface contaminants which can potentially adversely affect weld quality. After youve cleaned the metal make sure it is dry before you start welding. The Silver-Streak metal marker is able to make marks on metals that may be rusty wet or oily and will not scratch or abrade surfaces.

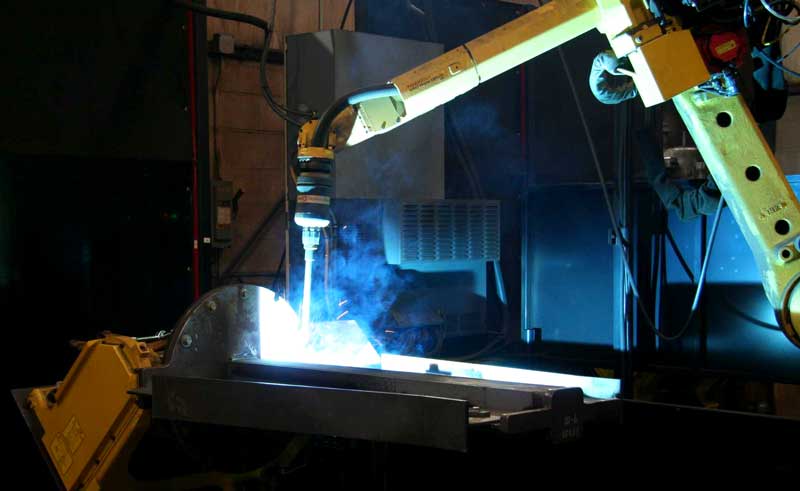

Todays manufacturing shops perform machining and stamping in their facilities typically take parts that have been treated with machining or press oil directly to their welding area. Welding is the most logical answer to this dilemma but it isnt always the best choice or the most viable one. Cutting too much of the surface off especially if the metal is thin will ruin the strength and shape of the metal.

MaterialOily Glue ColorAs-photo Product Size50g Quantity. Only clean shiny metal will take a strong bead from TIG. A forging operation is applied after the workpieces are heated up.

Granted some of the oil burns off during the welding process but some does not and adheres itself to welding particulates. The Welding High-Strength Oily Glue is formulated to give your broken items an instant bond. If you dont wipe down the metal there could be dirt dust and oils that will ruin your weld and can lead to defects.

Before you start welding ensure the clamp properly connects to the cleaned metal. How to Bond Metal to Metal without Welding Quick Easy Last Updated. When youre working with metal joining together two different pieces might become necessary.

Instantly and seamlessly glued back as its new. Oily parent material makes the welding process more difficult and may among other things cause poor results. Here is a partial list of things.

Some welding electrodes build up faster and others will penetrate deeper. Other electrodes may be restricted to the flat and horizontal or vertical positions or only the flat electrodes will weld on metal that is rusty oily dirty or galvanized with sufficient penetration. Never weld when the metal is wet.

Often no melt occurs thus a solid state weld can be obtained. 1 pc Packaged included. Metal for TIG welding needs to be ground or sanded then treated with cleaning agents to remove chemicals.

For stainless steel and aluminum that could mean a simple wipe with acetone. Clean bright metal means bare metal that is free from heavy oxides oil grease paint or coatings. As a general rule steel surfaces should be cleaned of any oil grease rust and mill scale before using any type of filler metal or consumable for any arc welding process.

Butt welding is a resistance welding process for joining thick metal plates or bars at the ends by directly applying opposing forces with electrodes clamping the workpieces. Use acetone to wipe off any oil then grind off the aluminum oxide with a specialist flap disc prior to welding. TIG weld only on clean bright metal.

It is PERFECT for ANY MATERIALS such as Metal Glass Rubber Ceramic Porcelain Wood Plastic Leather Paper Stone Fiber and even the hard-Acidic Woods. The marks made by this marker are highly visible and illuminate while making your cuts or welding. However sometimes complete cleaning of the steel surface cannot be performed.

Here is a full list of the things you can TIG weld. The Welding High-Strength Oily Glue is formulated to give your broken items an instant bond. Markal 96006 Silver-Streak Metal Marker.

Cracks damages loose ends on your favourite items might give you pain in the heart. But for hot rolled steel and chromoly more prep might be needed.

Mig Vs Tig Welding Simple Guide To The Differences

How To Clean And Prepare Metal For Tig Welding Welding Mastermind

Joining Processes Welding Welding Definition Material Joining Process

Buy Industrial Heat Resistance Cold Weld Metal Repair Paste A B Adhesive Gel 100g At Affordable Prices Price 6 Usd Free Shipping Real Reviews With Photos Joom

Buy Industrial Heat Resistance Cold Weld Metal Repair Paste A B Adhesive Gel 100g At Affordable Prices Price 6 Usd Free Shipping Real Reviews With Photos Joom

Old School Stick Welding Still Rules 6011 7018 Anyone

How To Properly Clean Your Metal For Welding Youtube

0 comments:

Post a Comment