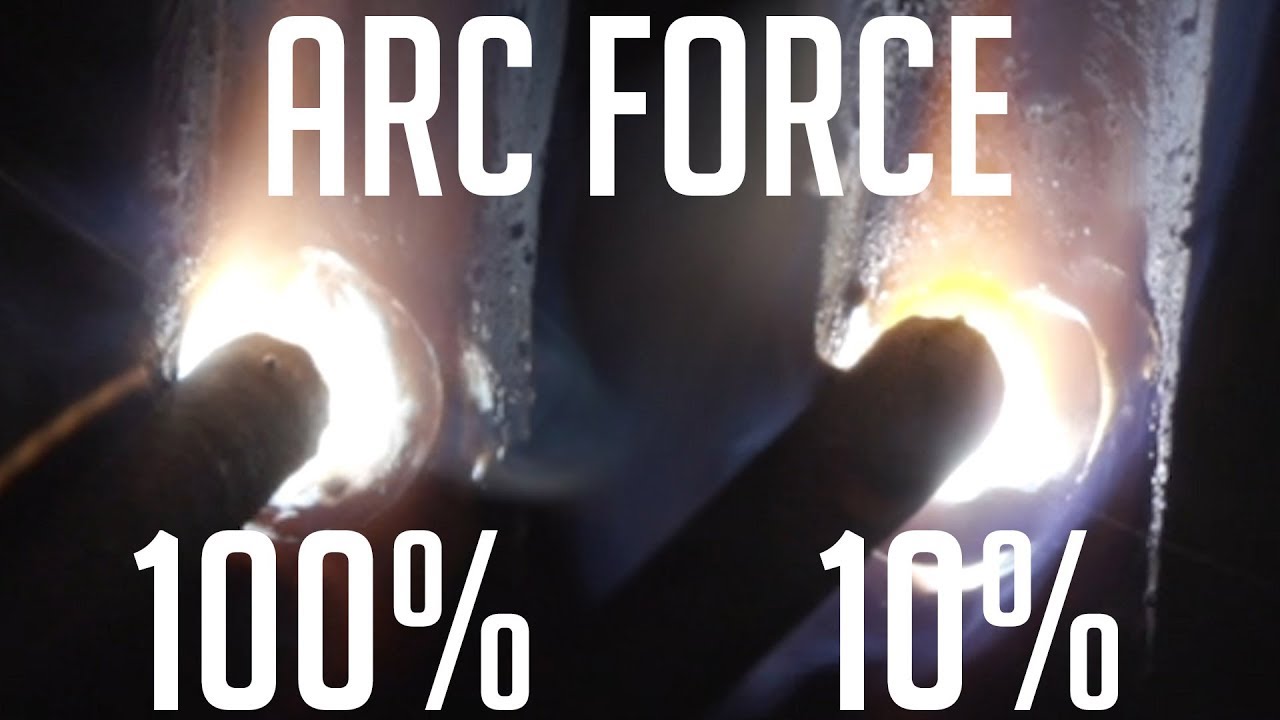

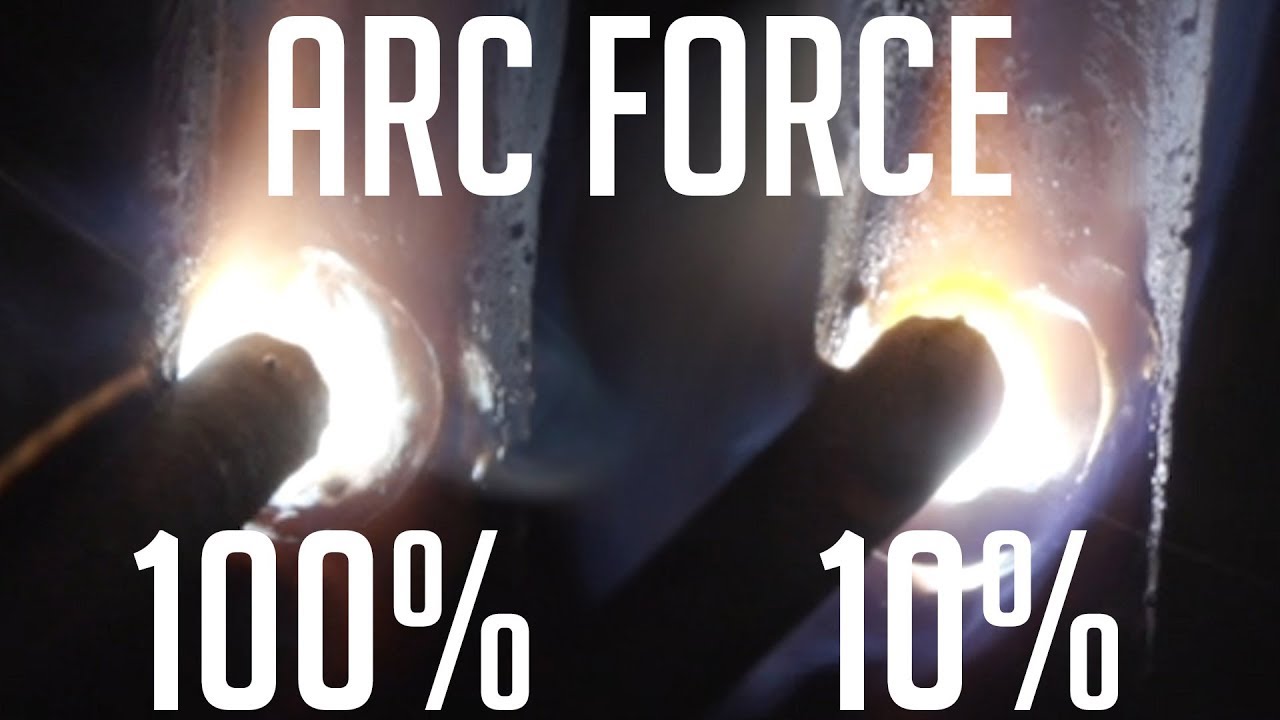

Arc Control or Dig bumps up the amps when the arc gets tight. In other words when you are just about to stick the rod thats why they call it stick weldingright the arc force bumps up the amperage just a bit so that you keep welding.

Arc Force sometimes called Dig or Arc Control is a similar feature to Hot Start except Arc Force operates during welding not just at ignition.

Arc force welding meaning. Arc Fource or Dig as it is called works like this. Arc force is a temporary increase of the output current during welding when the arc is too short. Of course this feature adds cost to the welder.

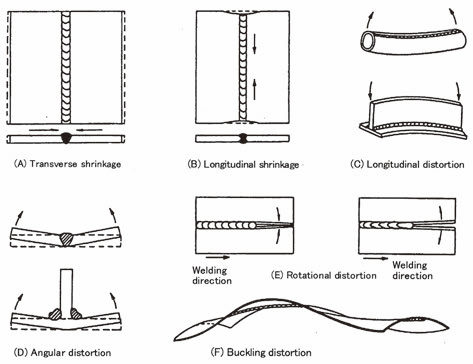

The only current variations you will have is when arc length gets longer or shorter voltage gets higher as arc length gets longer and goes down as it gets shorter. Scott Henion - My Welding Pages. In respect of welding influence of these forces on resisting or facilitating the detachment of molten metal.

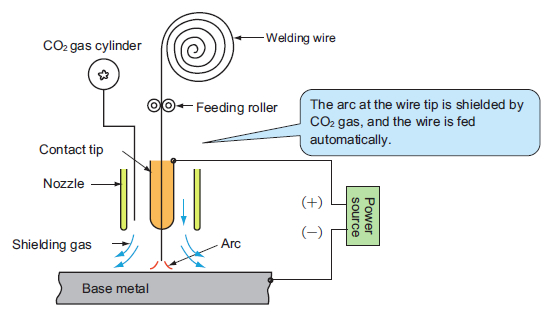

MIG Metal Inert Gas welding is a welding process in which an electric arc forms between a consumable wire electrode and the work piece. It also enhances simple position welding making the job easier. When the welding machine senses a short circuit it will deliver a peak of current.

Arc Welding Electrode A component of the welding circuit through which current is conducted and that terminates at the arc. Arc force automatically compensates by modifying the voltamp curve to maintain the. All the forces acting in arc zone are termed as arc forces.

Upon cooling and solidification a metallurgical bond is created. MAG Metal Active Gas welding is an arc. I have done some searching and I find advice to either turn up or turn down the Arc Force but cant find a good explanation of what Arc Force actually does.

Most operator manuals recommend setting the arc force knob to around 30 or so for 7018 rods. In a welding circuit the arc acts as a load resistor. Arc Welding Gun A device used to transfer current to a continuously fed consumable electrode guide the electrode and direct the shielding gas.

This feature supports production with consistently excellent arc performance. So it prevents against short-circuits. GIGATOOLS INDUSTRIAL CENTERNew APWelding Inverter Welding Machine with ARC FORCE TechnologyGenuine APWelding MMA-400 with ARC Force Inverter IGBT ARC Welding.

The electric arc is produced when two conductors are touches together and then separated by a small gap of 2 to 4 mm such that the current continues to flow through the air. AC-only welders are usually limited to arc welding while DC machines are available for arc MIG and TIG welding. AC welders tend to be smaller and more compact.

Ad Improve Your Business ROI - Get A Better Deal On Arc Welding Rods. Controls the arc response when an arc is held short and voltage begins to drop. What is Arc Force.

A power supply creates an electric arc between a consumable or non-consumable electrode and the base material using either direct DC or alternating AC currents. It also enhances simple position welding making the job easier. Control adjusts for a soft arc and fluid weld pool to a harsh arc and a stiffer puddle.

Ad Improve Your Business ROI - Get A Better Deal On Arc Welding Rods. This greatly assists in stabilizing the arc preventing the arc from cutting out while welding and preventing electrode sticking. Stick is done on a constant current type machine what this means is that you preset amperage say at 100 amps.

By applying intense heat metal at the joint between two parts is melted and caused to intermix - directly or more commonly with an intermediate molten filler metal. Arc welding is one of several fusion processes for joining metals. This feature supports production with consistently excellent arc performance.

Structure and Characteristics of Welding Arc. Since the joining is an intermixture of. It is a temporary increase of the output current during welding once the arc turns too short.

The arc welding is a fusion welding process in which the heat required to fuse the metal is obtained from an electric arc between the base metal and an electrode. AFAIK arc force is effectively an inductance control. Arc welding is a type of welding process using an electric arc to create heat to melt and join metals.

This process uses inert gases or gas mixtures as the shielding gas. If you really cant decide there are some welders available that can switch back and forth. A welding arc is a high current low voltage electric discharge operating generally in the range of 10 to 2000 amperes and at 10 to 50 volts.

This article is one of a series of TWI frequently asked questions FAQs. Argon and helium are typically used for the MIG welding of non-ferrous metals such as aluminium.

Principle Of A Cold Arc Voltage And Current Waveforms And B Cold Arc Download Scientific Diagram

Best Welding Rod Brand Welding Rods Welding Welding And Fabrication

Chapter 12 Flux Cored Arc Welding Equipment Setup

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

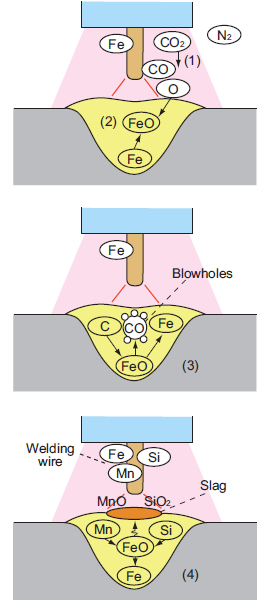

Fundamentals Of Co2 Arc Welding Education Center Kobelco Kobe Steel Ltd

Smaw Shielded Metal Arc Welding Definition Producing An

Fundamentals Of Co2 Arc Welding Education Center Kobelco Kobe Steel Ltd

What Does Arc Force Dig Actually Do Youtube

February 2013 Ocean And Me You They Everyone

0 comments:

Post a Comment