Provided welding fume exposure can be controlled to within limits welding can continue to take place. Welding in the workplace can present significant health hazards unless the potential and actual exposures to welding fumes are properly identified evaluated and controlled.

Fumes Health Safety In Arc Welding Weldfab Tech Times

Exposure to welding fume will be intermittent the highest exposures occurring during the welding operation ie.

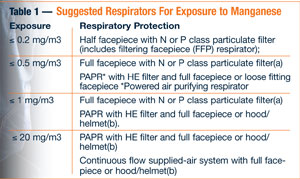

Exposure limits for welding fumes. The ACGIH has set an 8-hour TWA of 5 mgm 3 for these welding fumes measured as total particulate in the welders breathing zone. If a welder feels overexposed to the fumes he or she should stop welding and go outdoors for some fresh air immediately. APF 10000 Any supplied-air respirator that has a full facepiece and is operated in a.

General systems use natural or forced fresh air to keep welding fumes and smoke within safe limits. If the unease persists consult a doctor. All welding fume can cause lung cancer so you must put controls in place.

Welding fumes are a complex mixture of potentially toxic fumes and noxious gases. By breathing fume dust gas or mist. The exposure routes are.

This standard was set by ACGIH and proposed by OSHA. Reducing exposure to welding fume Welders should understand the hazards of the materials they are working with. It is the responsibility of the employer to ensure that exposure is reduced to as low as is reasonably practicable as stated within welding fume regulations.

However as limits are reduced exposure control becomes more difficult. Germany is not the only country to determine limit values for a welding fume maximum value. Exposure to a substance is uptake into the body.

How workers are exposed. Welders are at the highest risk for exposure to welding gases and fumes but anyone who works near a welder can also inhale welding fumes. In the past there has been particular concern about the possible cancer risks from welding stainless steel because of possible exposure to hexavalent chromium a known carcinogenic metal and tighter levels of control have often been advocated in these.

The accepted standard for exposure to welding fumes is an 8-hour time weighted average of 5mgm3 for welding fumes measured as total particulate in the welders breathing zone. Whilst in the US the maximum value is 5 mgm³. The Netherlands are eg.

For most substances contained in particulate welding fume the averaging period for the occupational exposure limit is eight hours. Welding is a widely used process in industrial activities and it is therefore important to ensure that welders are well protected from any hazard associated with the process. The supervisor and any co-workers back at the shop should be aware of the situation and how best to avoid the hazard.

This can often be accomplished via job sharing. That adds up to a potential pool of more than 700000 people who have been exposed to welding fumes. The most direct approach to limiting personnel exposure is simply to limit the amount of time an operator spends welding.

Some of the frequently observed diseases resulting from exposure to welding fumes and gases were discussed in Section 61221It is however imperative to notice that welding fumes are a complex mixture of metals and metal oxides and exposure to welding fumes is unique. At concentrations above the NIOSH REL or where there is no REL at any detectable concentration. This applies to specialist welders and workers who do some welding no matter how small the amount.

However even with the current. Workplace exposure limits What is exposure. Chromium nickel and manganese.

OSHA formerly had no limit for exposure to welding fumes which are defined as fumes that are generated by the manual metal arc or oxy-acetylene welding of iron mild steel or aluminum. Employers must also provide ventilation systems that keep hazardous chemicals below exposure limits. This is especially true indoors or in confined spaces.

During arcing or flame cutting. By injection into the. Pulmonary infections may also increase in terms of severity duration and frequency among welders following their exposure to welding.

OSHAs Permissible Exposure Limit PEL for CrVI is 5 µg m3 as an 8-hour time-weighted average. Some countries have occupational exposure limits for welding fume but others control fume by individual limits for the composition eg. For example an operator could spend half a day welding an SAW application and.

If youre unsure of how to measure this we suggest getting in touch with a local industrial hygienist to help measure air quality. Its best to suspend welding until the situation is resolved. By law you must protect your workers by controlling the health risks from welding fume.

Local exhaust systems use a movable hood to remove welding smoke at the source. OSHA regulates worker exposure to CrVI under its Chromium VI standard 29 CFR 19101026 and 19261126. APF 10000 Any self-contained breathing apparatus that has a full facepiece and is operated in a pressure-demand or other positive-pressure mode.

Another 200000 welders or more are retired. The control of cancer risk will require suitable engineering and COSHH control measures for all welding activities that take place indoors which includes Local Exhaust Ventilation Testing. Even more restrictive than Germany with a limit value for respirable dusts of 1 mgm³.

A minimization requirement applies to carcinogenic substances. In those areas fumes cant dissipate and hazardous levels can build up. HSE has issued a safety alert about the health risks of welding fume.

These include general and local exhaust ventilation systems. Fume exposure depends on the metal being joined the welding process and the circumstances of the work but levels can be in excess of 10 mgm3. The health effects of welding fumes have been studied for a long time and great effort has been made to mitigate exposure to welding fumes.

Fumes Health Safety In Arc Welding Weldfab Tech Times

Breathe Freely Controlling Exposures To Prevent Occupational Lung Disease In Industry Monitoring Exposure To Welding Fume

Fumes Health Safety In Arc Welding Weldfab Tech Times

Dealing With Welding Fumes Resources American Welding Society

Fumes Health Safety In Arc Welding Weldfab Tech Times

Ph And Solubility Properties Of Welding Fumes Download Table

Welding Fumes V What Are Welding Fumes V

The Results Of Risk Assessment For Welding Gases Download Scientific Diagram

Assess Your Welding Fume Exposures 2013 05 09 Ishn

0 comments:

Post a Comment