To estimate the feature welding time for an assemblage we propose an approach based on the evaluation of the welding section from a geometric modelling. Then multiply times 4 minimum and bid with that figure.

Calculate Man Hours How To Estimate An Offer And Manage New Projects Welding Gas Mold Release Electric Arc Welding

For example on a 4 inch diameter pipe I project 12 hour set up and calculate weld time this way 4 X 60minutes 240minutes 3600 minutes divided by 240 15 or 15 Pieces per hour.

How to estimate welding time. As a simple exercise next time you stroll in the welding shop just ask the person in charge what is the filler metal weight used per unit weld length or per hour of the three most important welding jobs currently being performed. At this point the labor and overhead cost required to deposit that pound of weld metal can be determined by multiplying this time value by the stated labor and overhead rate of. Wait a minute I forgot you were welding pipe which so much harder to weld.

Filler wire used measured as wire weight or wire length consumed. Keep up with the time multiply that X the circumfence of the pipe then allow for fit up. How do you know.

Welding Estimator is a quick and easy-to-use weld welding procedure and welding project cost estimation tool which allows you to find the most cost-effective process for your weld. The total area of the two red regions is therefore given by the formula 2 t-r tan b x t-r2 or t-r tan b x t-r. Apply an arc on factor to take account of the fact that no one ever welds 100 of the time.

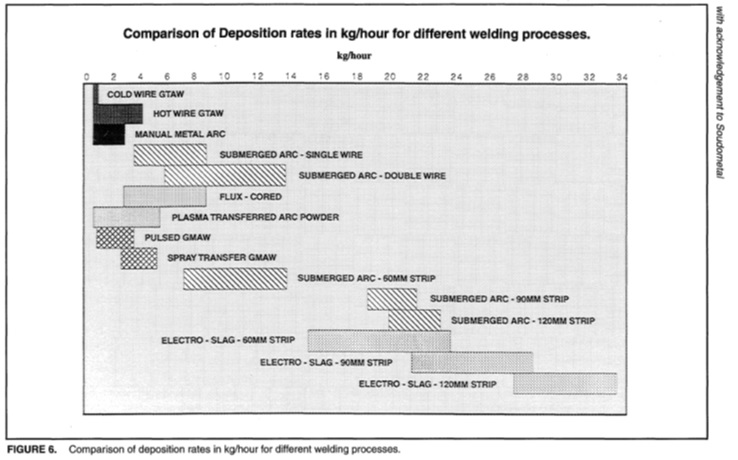

You will need to calculate the time it would take to deposit the necessary mass of weld metal based on a deposition rate for the particular welding process that you will be using. Depending on the complexity of the component or structure. Determine the arc and its length burning area.

Units of production per dayweekmonthquarter depending on manufacturing volumes. 2- Consumables wire brush grinding discetc. This value assumes a 100 arc on time.

They do not want to know what time you took to weld or what it cost you to make the weld. Arc-on time as a percentage of an overall welding task in hours per weekmonthquarter. This equation can be a great starting point for any welding business.

This is called the Weld Deposition Rate. Let estimate the cost of the welding with this deposition the rate of the process. Material Cost 1- Welding machine depreciation or rent.

Weld a test plate 12 thick x1ftlong with the same bevel and backing as the pipe. Create and compare full costing reports to make sure you get the best value for money for your job while making sure you meet your project timescales in the most cost-effective manner possible. One way is to estimate total length of weld and use a time of 60 seconds per linear inch with set up time separated.

How to Calculate Weld time in cycles. We had better ask a pipe welder. And fringe benefits 2- Overhead cost.

More time can be saved by good planning and effective crane equipment and procedures. Manpower cost 1- Welder Craft Cost It is pertinent with his productivity and salary Paid to emp. Resultant metrics for calculating welding productivity might take into consideration.

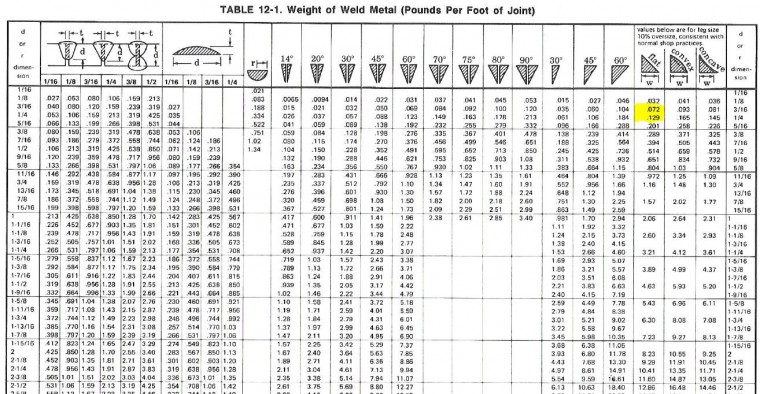

This time to deposit one pound of weld metal is listed in Table 2. A welding time estimated as ten minutes ends up taking fifty minutes when turning and handling and spatter removal is taken into account. The most important item learned is that welding time is really not as important as welding salesman tell you.

From this amperage a deposition rate in pounds per hour is determined and then the total welding time for one pound of deposited weld metal can be calculated. To calculate the welding cost you need to consider the below elements. Hourly Rate Multiplied by the Hours Worked Divided by the Inches Welded that Day hr X hw iw If a welder does 200 inches a day and your overhead cost is 50 an hour times 8 hours that would be 400 divided by 200 inches you would charge 200 for every inch of welding.

Weld time and is denoted by τ symbol. April 18th 2018 - Pipe Welding Time Estimation Pdf Free Download Here TECHNICAL CALCULATION AND ESTIMATOR S MAN HOUR MANUAL Http Www Estimations Info TCAEMM Emptyvaluesdocument Pdf Calculate Welding Time Welding Bonding Amp Fastener. The dimension c is given by tan b x t-r.

The customer wants to know how much it will cost them for the weldment. A mock-up may be used to determine the time to lay-out fit-up and weld. Weld time in cycles calculator uses time_in_cycles 236Thickness of first material Thickness of second material to calculate the Weld time The Weld time in cycles is a typical welding schedule whose time elements are measured in terms of the time unit for a cycle of AC.

EXAMPLE 1 Welding Time WtFt of Weld x Ft of Weld Deposition Rate x Operating Factor Substituting the values in Example 1814 x 1280 536 x 30 1042 1608 648 Hrs. An estimator himself must choos e the v alues and define the man hours taking into account all the elements that might hav e any influence on them.

Calculating Welding Costs And Times Explained

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

How To Calculate Direct Material Cost Examples In 2021 Directions Cost Example

How To Calculate Overhead Costs Man Hour Types Of Taxes Cost

Calculate Man Hours How To Estimate An Offer And Manage New Projects Electric Arc Welding Construction Estimator Mold Release

Welding And Fabrication Service Invoice Template Invoice Template Estimate Template Invoice Template Word

Calculating Weight Of Weld Metal Required Welding Answers

Welding Estimates Templates Google Search Estimate Template Templates Welding

0 comments:

Post a Comment