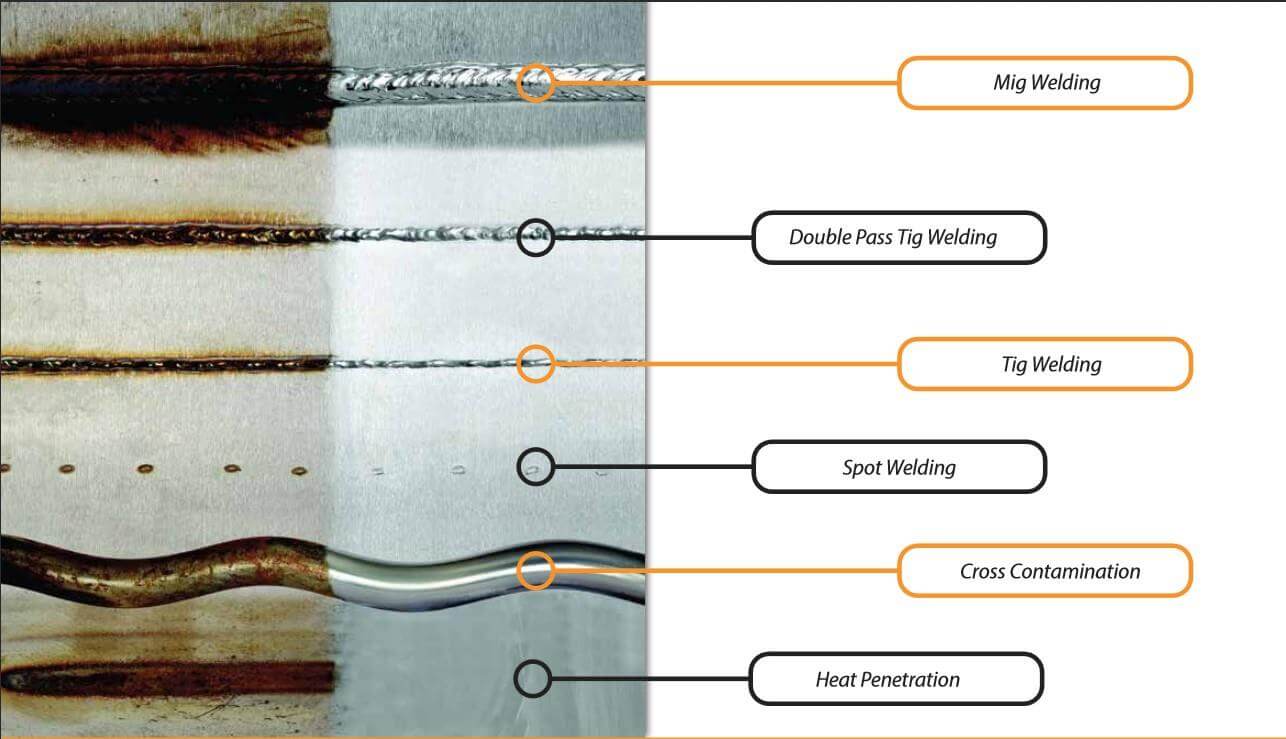

Pickling paste has long been a standard way to remove heat tint from stainless steel welds. The best way to clean stainless steel after welding is through a process called electropolishing.

How To Clean Stainless Steel After Welding Welding Headquarters

Shops that do lots of stainless work have large tubs of acid for soaking off heat tint.

How to remove welding marks on stainless steel. The Step-By-Step Process to Weld Stainless Steel Both MIG TIG Welding So now that we have all the pieces in place lets combine them and get the actual job done. Several methods are commonly used to remove discoloration on stainless steel after welding electrochemical cleaning chemical pickling and mechanical grinding brushing are just few of them. Acid Baths to Remove Stainless Steel Welding Heat Ting.

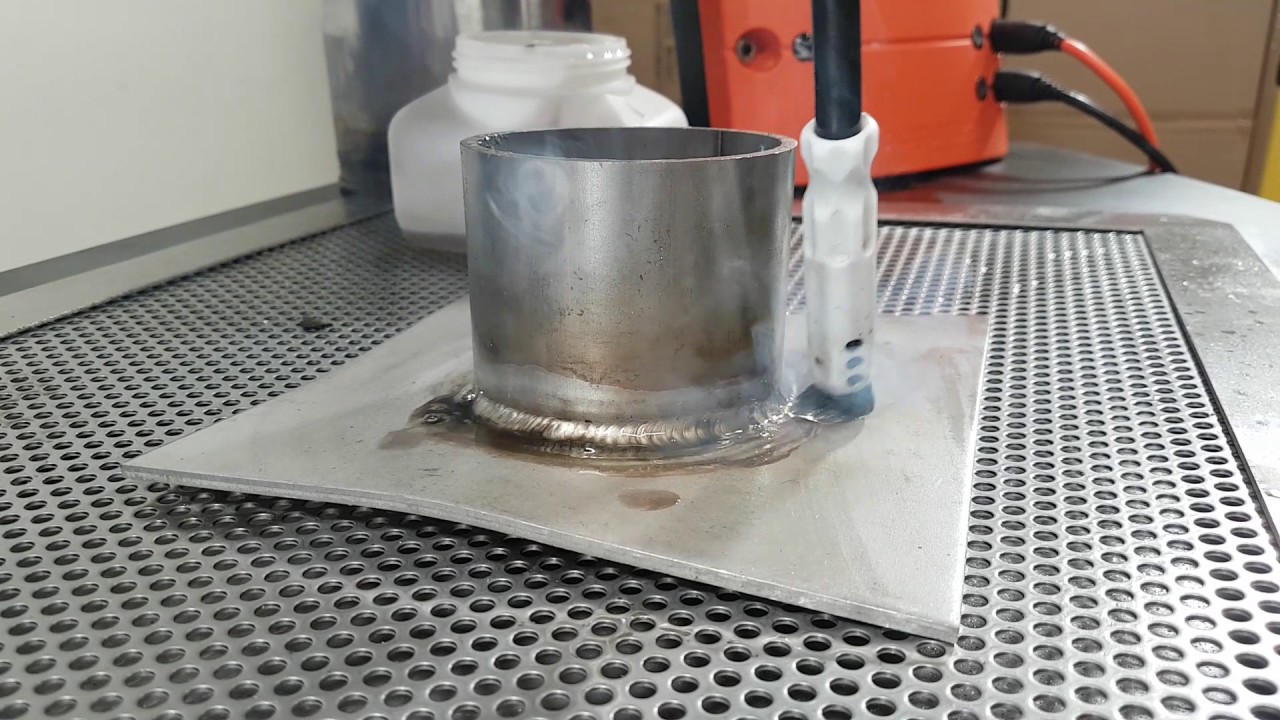

Typical weld paste for pickling of welds will remove the heat effected discoloration heat tint that you see. This way you can remove the acid residue before it alters the appearance of your stainless steel component. If youre planning to clean stainless steel welds on your own your best options are mechanical methods like electropolishing and neutralization.

Makes some products from nylon impregnated with a mineral that will clean those marks. By using a specialised laser on your metalwork you will be able to remove some if not all of the blemishes that come from your metals exposure to heat during the welding process. Stainless steel passivates - forms that thin chromium oxide film - just by exposure to air.

The paste made from hydrofluoric acid and nitric acid is applied to the affected areas using a brush or spray then later removed and neutralized with a neutralizing agent. This will serve as a cooling mechanism or heat sink absorbing the heat while preventing any burn through. To polish a gentler abrasive is used in combination with polishing compounds.

The oxygen content in the back shield must be controlled prior to the start of welding and should be minimised. Click to read more about these methods However the choice of method depends largely on the scope of the problem. This is the number one most crucial thing every welder must do before beginning to weld.

They will have to be abraided mechanically. It is generally a blend of nitric and hydrofluoric acid in a gelled solution. An efficient back purge will minimise the formation of heat-tint.

In order to restore corrosion resistance the scale and the Cr-depleted layer must be removed by post-weld cleaning. Put On Your Safety Gears. The type of polishing abrasive you use will depend on the level of finish you require.

The iron comes from contact with tools clamps steel or cast iron tables shear blades et cetera. The electrochemical process will not only remove imperfections on the surface after welding but it will also restore the oxide layer that returns stainless steel back to its normal passive state. Note that neutralization is most effective when you do it right after welding.

This will make it easier to keep the sanding block flat against the part. Unitized wheels can remove welds and leave a satin to mirror blended finish. Stainless steel pickling paste which is a nitric acid based compound I believe works very well for removing weld discoloration without altering the.

All you need do is remove iron contamination and heat tint the blue color each side of the weld. The benefits of using laser is that its quick clean and effortless. Soaking the weld joint in a bath of nitric or hydrofluoric acid will remove the heat tint with ease.

Non-woven wheels will not remove the weld but will deburr blend and give a satin finish. Passivation is the removal of exogenous iron or iron compounds from the surface of stainless steel by means of a chemical dissolutionmost typically by a treatment with an acid solution that will remove the surface contamination but will not affect the stainless steel parts where i work we have a machine that we ground to the welded part then there is a hand held part that you slide a sock type cotton over and put in the acid solution and rub across the welds. One way to prevent warping when welding stainless-steel is to clamp a piece of brass or copper behind the seam of the weld.

This process involves the oxidation of an acidic electrolyte on a metal surface with the help of electricity. After removal of the heat tint passivation should be performed with either nitric or citric acid gel passivation. It could also help you weld the entire seam continuously.

To remove the grinding marks the material in the high portions of the grinding marks must be removed to match the low spots without making the low spots deeper. Chemicals or sprays wont remove the burn marks. Electropolishing not only clears the surface from stains but it also helps the metal become properly passivated.

At first you need to put on your welding jacket or at least a full sleeve shirt in. Unlike grinding this cleaning method will successfully remove all dirt and discoloration from the welds. The product is called Scotchbrite and is sold in rectangular pads or wheels that attach to an electric drill.

Place the steel part to be polished in the vise in such a way that the steel lies parallel to the vise or ground.

Electrochemical Weld Cleaning The Fastest And Safest Way To Clean Stainless Steel Welds Cougartron

Diy Stainless Steel Weld Cleaning Electropolishing Stainless Steel Welding Stainless Welding Welding Tips

Chemical To Clean Weld Marks From Stainless Steel Or Procedure To Remove The Burn Marks

Chemical To Clean Weld Marks From Stainless Steel Or Procedure To Remove The Burn Marks

Electrochemical Weld Cleaning For Stainless Steel Youtube

How To Remove Heat Tints Discoloration After Welding Cougartron

How To Clean Stainless Steel After Welding Welding Headquarters

Cleaning Stainless Steel Welds Quickly And Safely Passivation Of Stainless Steel Welds Using Ensitech Tig Brush Stainless Steel Welding Stainless Steel Cleaning Welding Tips

Cleaning Stainless Steel Tig Welds Youtube

0 comments:

Post a Comment