Without application of welding curren andthe projection is compressedand intended into the surface of the mating workpieces Fig. Basically a protrusion is placed on one of the two materials to be welded.

1 Specification Machine Of Spot Welding Wim Mc 8 Download Table

Earlier research on projection welding primarily relied on an all-exper-imental approach in which the heating process and nugget formation are quali-tatively depicted using either consecutive metallurgical cross sections or high-speed movies.

Projection welding research. While only 80 percent as strong as traditional resistance welds projection welds contribute significantly to reducing the weight and production costs of automobiles explains Muschong. ISODIS 14373 Resistance welding Procedure for spot welding of uncoated and coated low carbon steels. A comprehensive thermal-electrical-mechanical analysis was performed to quantitatively simulate projection welding.

Danish research project INNOJOINT on numerical modeling of resistance and friction stir welding processes for 4 years 2006-2010 which is financed by the Danish Research Council with a consortium of five departments from DTU and SWANTEC as the sole industrial partner. Projection welding not unlike other re-sistance welding processes is difficult to analyze. According to Mary Bonkwelding is the process of.

Empirical research has been performed to offer new approaches for improved joint strength and to increase knowledge on cracking mechanisms in resistance projection welding and resistance spot welding of UHSS. Relevant research papers by the worlds foremost scientists engineers teachers and industry professionals are published monthly in the Welding Journal and are also available for download in PDF format. Heating and melting metal parts to join them together Bonk3.

Projection welding is an ideal method of fastening attachments eg. EN 28167 Projections for resistance welding ISO 81671989. Resistance Projection Welding RPW Fundamentals The resistance welding is a pressure joint based in the melting of materials produced from the Joule effect in the contact surface electrical resistance between them generating heat during the flow of.

Projection welding is a variation on resistance welding. The global Projection Welding Equipment Market research report focuses on the confined major statistical overview for the Projection Welding Equipment industry as it offers our readers a value addition on guiding them in confronting the obstacles surrounding the market. Finally future work to extend this method in optimizing projection welding process design is.

The agreement between the experimental and numerical results is satisfactory indicating that the incrementally coupled finite element method may be suitable for projection welding research. Projection welding using capacitor discharge projection welding machine is gaining popularity in production of sheet metal works in industry. Browse current peer-reviewed reports of research on welding procedures metallurgy equipment processes testing and quality control.

Projection welding is widely used in fabrication of pump impellers for bottling plants milk plants and. Machine uses electricity to melt the electrode fusing one piece of metal to. This projection is then brought into contact against the second material.

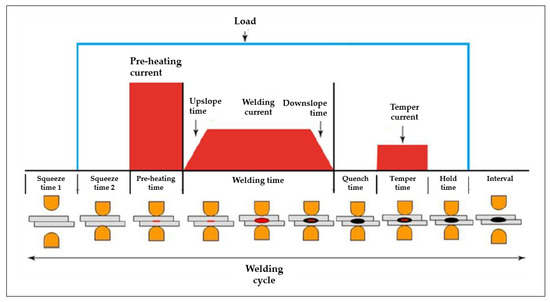

As the current flows through the welding zone of whichthe path is constrained by the contact the temperature around the projection elevates rapidly. These projections are used to concentrate heat generation at the point of contact and therefore to generate a. The welding machine uses a ground that connects to the surface that.

It is one of the most economical methods of projection welding ever known. By optimising the current build-up phase and peak current during the first milliseconds of weld time it was shown that the strength. Short length T joints eg.

Collapsed during tltis stage Fig1c2. Welding is or how it works. Were reducing our flange size by 75 percent in some cases Muschong reports describing The.

14 or 15 can be made by forming projections in. An exhaustive addition of several factors such as global distribution companies data market size and market factors. Brackets spigots and weld nuts to sheet metal where there is access from only one side and for making attachments to solid forged or machined parts.

Weld and heat-affected zone microstructures were examined to check for any imperfections such as pores and cracks and to provide an understanding of the tensile properties of the weld. Projection welding is a vari - ation of resistance welding in which cur - rent flow is concentrated at the point of contact with a local geometric extension of one or both of the parts being welded. With the advances in.

The research work was carried material AISI 1080 by using processes of derusting and oiling. Modeling of projection welding processes using coupled finite element analyses.

Welder Knowledge Welding Projects Welding And Fabrication Welding

Pdf Design And Simulation Of A Spot Welding Process

Pdf Projection Welding With Pneumatic And Servo Mechanical Electrode Pressure System In Fem Calculations Comparison

Metals Free Full Text Optimization Of The Resistance Spot Welding Process Of 22mnb5 Galvannealed Steel Using Response Surface Methodology And Global Criterion Method Based On Principal Components Analysis Html

Unoffical Weld Symbols Welding Tips Welding Art Weld

Gekamac Mig Mag Welding Machine Gedik Welding Istanbul City Turkey In 2021 Welding Machine Mag Welding Welding

0 comments:

Post a Comment