Force is determined in the same manner. Can be welded to larger components.

Resistance Projection Welding Working Of Resistance Projection Welding

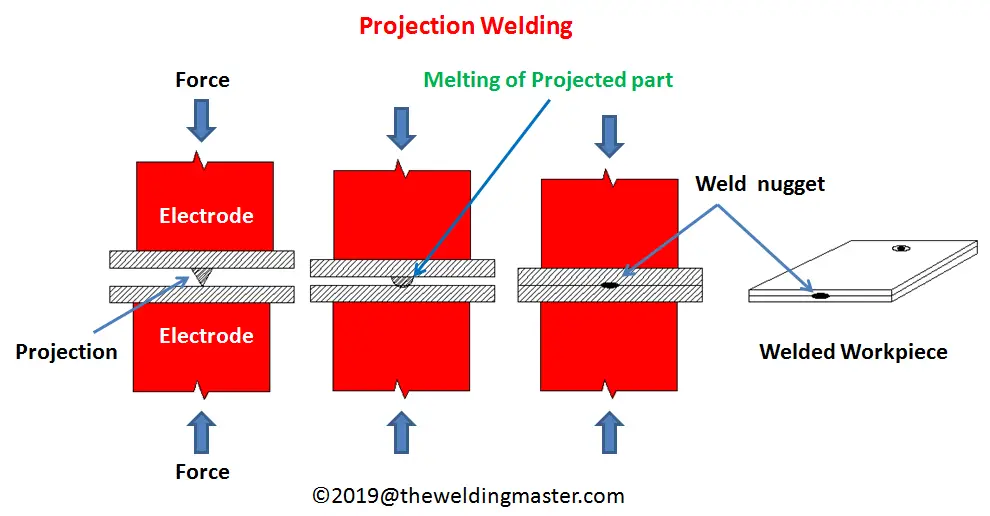

Projection welding is a resistance weld where the design or shape of the part is used to make the desperate individual point contacts to concentrate the current during the welding process.

Projection welding uses. Projection welding is often used to manufacture weld nuts and weld bolts. This method is broadly divided into two types. Projection welding is generally used for projects with thicker materials around 0035 and thicker.

250 mm Weld controller. Projection welding is one kind of resistance weld where the shape or design of the part is used to make subtle point contacts to concentrate the current during welding. Applications of Projection Welding.

Single tandem or servodrived welding heads. Conventional spot welding involves passing a high tension electric arc between two electrodes on either side of the material to be welded. Serratron 1B MFC-3000 Brass platforms Double pressure Automatic nut or bolt feeder in option.

Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding. Multiply the current by the number of projections if they are far apart if close together adjust to a lower multiplier. Nuts and bolts are often assemble to.

Equipment used for projection welding is similar to that used for spot welding except that the rod electrodes are replaced by flat copper platens or dies as shown in Fig. From 100 to 1020 kVA Max. Projection Welding is most commonly used when special nuts small fasteners special bolts studs and similar parts are used as projection on the portion of the part to be welded.

Projection Welding is also used for welding parts of refrigerator condensers refrigerator racks grills etc. A fourth projection design is the corner projection commonly used to plug a hole in a reservoir. 14 or 15 can be made by forming projections in.

Weld sections of typical projection welds are shown in Figure 3. If a projection weld schedule is not available and a spot weld schedule for the same material is available use it as a guide. Usually two or three projections are welded at the same time.

This causes localized melting of the two materials thus creating a spot weld. This page introduces projection welding a method that adopts resistance welding principles. Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding.

Projection Welding AC-MF Powers. From 750 to 3600 daN. Iii Projection welding is used for welding of refrigerator condensers crossed-wire welding grills etc.

Projection welds developed via the resistance welding RW process use the design or shape of the part to make discreet individual-point contacts to concentrate the current during welding. Short length T joints eg. I It is usually employed on punched where the projection automatically exists.

With more than three simultaneous welds however there is a tendency for lack of consistency and the welds. What is a Projection Weld. Projection welding is a resistance welding process of joining two sheets or a sheet and a thick component or a small component like nut to a big body like automotive chasis by making raised portions or projections on one of the components where weld nugget is required to be made.

In most applications many small projections are made on one surface of the parts to be welded. Coined projections are common on welding nuts while machined projections often are used to make circumferential projections to form a hermetic seal. Ii Small fasteners nuts etc.

Benefits of Projection Welding Techniques Projection welding is very easy to maintain if the fundamentals are taken into consideration in the first place. Steel wire shopping carts wire racks and other cross wire products are all projection welding. While it can be also used to join thinner metal pieces together that tends to be a.

Projection welding is an ideal method of fastening attachments eg. Mostly in almost all applications with various small projections are molded on single parts surfaces which need to weld. Time will be the same as a.

Embossed projection welding and solid projection welding. From 26 to 205 kA. Brackets spigots and weld nuts to sheet metal where there is access from only one side and for making attachments to solid forged or machined parts.

Projection welding is commonly used for sheet metal fabrications.

Resistance Seam Welding Rsew Advantages And Disadvantages

Electron Beam Machining Principles Electrons Vacuum Pump Principles

Projection Welding Working Advantage Disadvantages And Applications

What Is Projection Welding Working Principle Advantages Disadvantages And Application The Welding Master

Resistance Projection Welding Working Of Resistance Projection Welding

Basic Units Of Ajm Gas Supply Jet Machine Abrasive

Resistance Projection Welding Working Of Resistance Projection Welding

0 comments:

Post a Comment