Welding or cutting in enclosed spaces such as tanks can seriously deplete the oxygen content of the air. 30 REFERENCE This safety policy and procedure is.

Welding And Flamecutting Poster Maritime Progress Ltd Maritime Progress Ltd

Ad China Sale Welding Machine.

Welding cutting safety procedure. The PPE you receive will include. Care must be taken to avoid the contact of the flame with any combustible substances. Trusted China Suppliers Verified by SGS.

Be responsible for the safe handling of the cutting or welding equipment and the safe use of this equipment during the cutting or welding process. Connect the cutting hoses to the regulators with hose clamps. Such explosions have killed people.

Adequate ventilation is essential supported by the welder wearing an air- supplied respirator when necessary. The oxy-fuel process utilizes a flame to generate heat for cutting welding and brazing. Ensure torch tips are cleaned as per manufacturers recommendations.

Cutting and welding tasks are performed either on a routine or infrequent. Performing any welding cutting andor brazing. OSHAs safety management guidelines offer safety managers a framework for preventing hot work injuries and fatalities.

Welding helmets with side-shields. Thec COP is intended to be read by proprietors contractors line. Keep the cylinder upright and away from hot jobs.

Although procedures may look different from company to company this sample safe work procedure for welding will help you develop yours. All cutting and welding operations performed at Tufts by Tufts personnel or contractors must be carried out in accordance with standards set forth by the American Welding Society and the appropriate American National Standards Institute ANSI standards concerning cutting and welding. Health and Safety Executive Safety in gas welding cutting and similar processes Page 4 of 11 Explosion when cutting up or repairing tanks drums and tyres Figure 2 Cutting up scrap If a welding blowpipe or burner is used on a tank or drum containing flammable material solid liquid or vapour it can explode.

Ensure electrical cord electrode holder and cables are free from defects no cable splices are allowed with 10 feet of the electrode holder. Cutting Welding Procedures. Rhodes MA CSP CPCU PHR.

A firebrick top workbench is recommended for cutting on. Safe Work Procedures must be developed and implemented for the work carried out at every workplace. They are developed by summarizing important information identified through Job Hazard Analyses.

Rhodes EdD CSP and David P. Determine the combustible materials and hazardous areas present or likely to be present in the work location. The degree and type of ventilation will depend on the specific welding and cutting operation.

SAFETY IN GAS CUTTING. Ad China Sale Welding Machine. These welding and torch cutting operations occur at but are not limited to equipment repair shops equipment fabrication shops and construction operations such as bridge and road repair and maintenance.

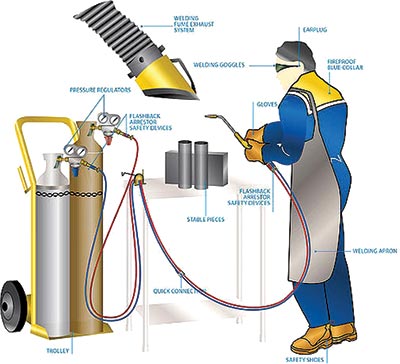

Ensure PPE welding hood gloves safety shoes and aprons are available and have no defects. For works inside the confined space refer to Safe Work Procedure for Confined Space Entry. Perform safety check on all equipment.

Guidelines for Developing a Welding and Cutting Safety Program. Ensure that you have adequate. It also describes the steps and measures to be taken in protecting workers from the hazards arising from the work and in reducing injuries and damage aused by fire and explosion.

Welding helmets protect you from UV radiation particles debris hot slag and chemical burns. Leave the work area in a safe clean tidy condition. Your employer or manager has a duty to provide you with appropriate Personal Protective Equipment PPE.

Fix the DA and oxygen regulator to the respective cylinders after ensuring free from dirt or grease. Blue or black hoses for oxygen and red for DA. Always Wear Appropriate PPE.

Welding and cutting safety procedure PURPOSE This Procedure provides safety and health instructions regarding gas and electric welding cutting brazing or similar flame or spark-producing operations to protect personnel and property against heat evolved gases and fumes electrical shock and radiation. Ensure fire extinguisher is charged and available. This safety policy and procedure affects all employees who are exposed by their job duties to welding and torch cutting operations.

Therefore you should follow the safety precautions below to protect yourself at work. 111 This Code of Practice the COP recommends safe practices in gas welding and flame cutting. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work.

Provide enough ventilation wherever welding and cutting are performed. Trusted China Suppliers Verified by SGS. Proper venti- lation will protect the operator from the evolving noxious fumes and gases.

How To Use Welding Machine Safety

Doshti Welding And Cutting Safety Procedure

Hazards In Welding And Cutting Industrial Health Safety Review

Doshti Welding And Cutting Safety Procedure

Welding And Cutting Safety Procedure Media K3 Indonesia

Safety Training Posters Operational White Vinyl Poster Welding And Flamecutting 1033wwv

Gas Welding And Cutting Safety Authorstream

Welding And Flamecutting General Safety Products Safety Signs Posters

Welding And Cutting Safety Safety Unit Lesson 5 Oxy Fuel Welding Cutting Oxy Fuel Welding And Cutting Are The Most Common Causes Of Fires In The Welding Ppt Download

0 comments:

Post a Comment