Please register or sign in to view prices and order. Ad Find China Manufacturers Of Aluminum Welding.

Tig Welding Process Parameters And Aluminum Brazing Is One Of The Premiere Welding Procedures That Everyone Knows Welding Welding Process Tig Welding Process

Praxairs Stargon AL welding blend is an advanced shielding gas for welding aluminum.

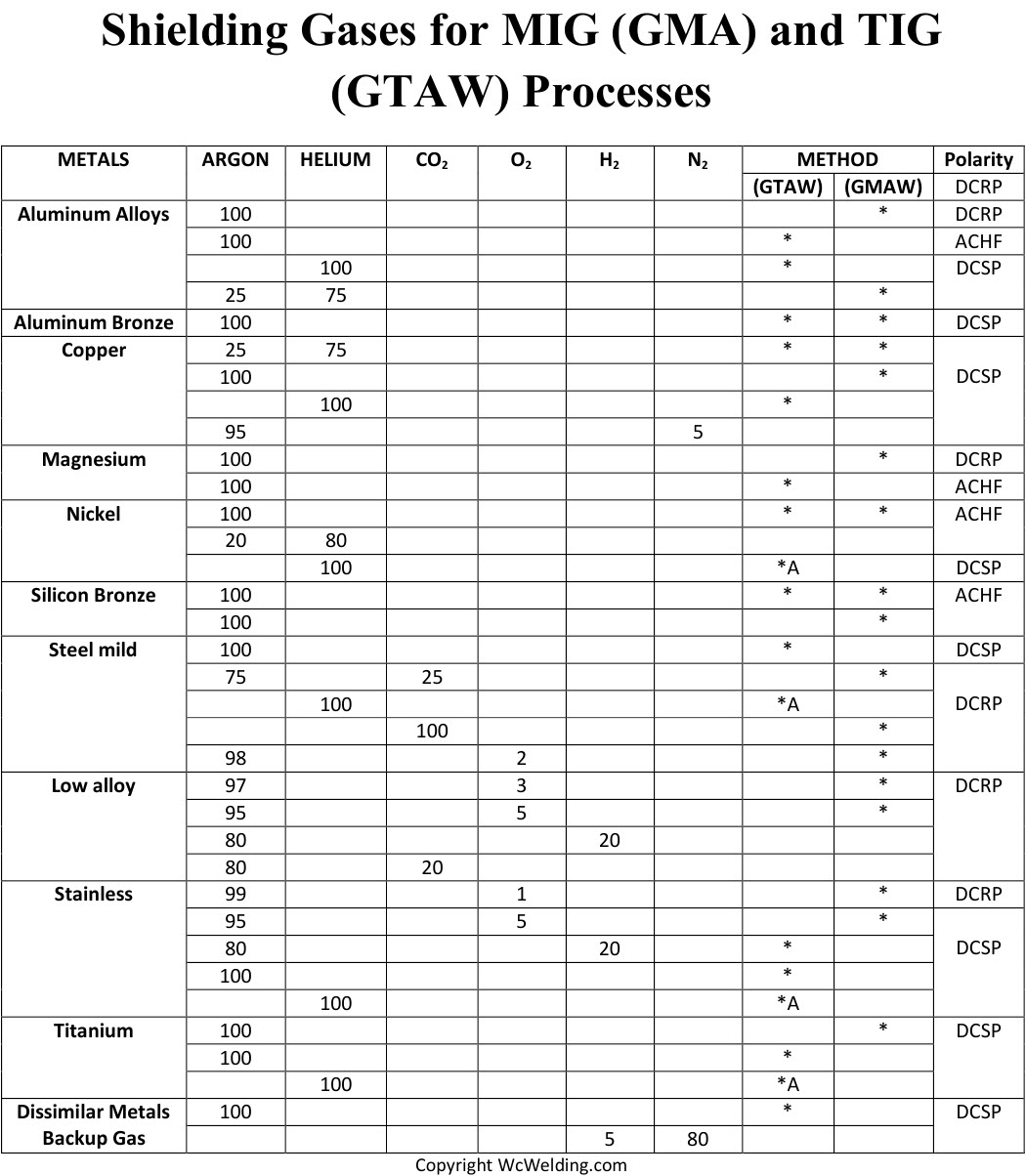

Best shielding gas for welding aluminum. For both TIG Welding Gas Tungsten Arc Welding or GTAW and MIG Welding Gas Metal Arc Welding or GMAW use pure argon for aluminum materials up to ½ in thickness. Flow rates of 20 to 30 cubic feet per. Pure argon is the preferred shielding gas for welding thin sections of aluminum.

Again many welding supply stores carry their own mixture that can improve the weld quality and ease of welding on stainless steel. Ad Find China Manufacturers Of Aluminum Welding. Argon offers good stability in your arc and doesnt require as much clean up afterward because the arc is narrow and concentrated.

Aluminum is non-ferrous metal and therefore you should only use 100 argon as the shielding gas. The most popular type of shielding gas in TIG welding is 100 pure argon. Argon is the main shielding gas used for Tig Welding most metals and Mig Welding Aluminium or Mig Brazing.

Mixtures of argon and helium are probably the next common and pure helium is generally only used for some specialized GTAW applications. What type of shielding gas should I use for aluminum welding. Choose the right gas.

The most common gases used by recreational MIG welders include 75 argon blended with 25 carbon dioxide also known as C25 or MIG-mix and pure carbon dioxide C100. Two-part shielding gas blends are the most common and they are typically made up of either argon helium argon CO2 or argon oxygen. For a pure 100 percent argon shield gas a flow rate of 20 to 30 cubic feet per hour is recommended when welding aluminum.

Argon accounts for 1 percent of air and is a by-product of the air-reduction processes used to produce oxygen. Argon or argonhelium mixtures can be used for welding all grades. Because aluminum is a non-ferrous metal it requires a 100 percent argon shielding gas.

Some gases are better suited than others for the most commonly used base materials whether its aluminum mild steel carbon steel low-alloy steel or stainless steel. All-purpose shielding gas for general fabrication of carbon steel typically in the 4-12mm range. Also do you need argon gas to weld aluminum.

What Else Can Shielding Gas Do. Stargon AL welding blend is a carefully prepared proprietary blend of argon with precisely controlled ppm parts per million additions of active gases and it is versatile for use in both GMAW and GTAW weld processes. This is because argon in its pure form can be used on every type of base metal including for the notoriously finicky TIG welding aluminum.

Helium He can be added to increase penetration and fluidity of the weld pool. This gas is good for shielding welds in the flat position and in deep groves. Argonhelium binary blends are useful for welding nickel based alloys and aluminum.

Each gas has benefits and drawbacks in any given application. Generally you will be using a pure argon shielding gas when you are MIG welding aluminum. Aluminum has an interesting property that requires a specific gas to be used while welding.

Stainless Steel MIG weld done with C2 gas. Pure argon is the most popular shielding gas and is often used for both gas metal arc and gas tungsten arc welding of aluminum. While protecting the weld is the priority the basic properties of gases used in MIG welding affect the process in other ways.

Argon helium CO 2 and oxygen are the most common shielding gases used in GMAW. Shielding gases for MIGGMAW welding The basic gas for MIGMAG welding is argon Ar. In some cases there is tri-mix shielding gas containing 90 Helium 75 Argon and 25Carbon dioxide.

Shield Gases like oxygen have much higher pressure and can lead to a huge safety threat due to it with pressures near 3000 psi Gases Shield Gas. The most commonly used Inert gas is Argon. MIG Welding Gas for Aluminum Welding.

Setting Up The Shielding Gas. Thicker sections of aluminum pieces may need some mixture of argon and helium for thicker sections where high heat input welds are being deposited. As I said earlier argon requires a higher flow rate and the recommended.

Miller Mig Welding Tips Intro Welding Welding Tips Welding Projects

Gas Flow Rates For Tig Welding Welding Rods Welding Rod Chart Welding Gas

Gtaw Gas Tungsten Arc Welding Or Tig Welding Machine Process Is Weldingis Com Tig Welding Welding Machine Tungsten Inert Gas Welding

The Primary Techniques Used For Fusion Welding Are Gas Welding Metal Arc Metal Inert Gas Mig Tungsten Inert Gas Tig Ho Welding Tips Tig Welding Tips Gtaw

Pin By Ixl Idol On Woodwork Shop In 2021 Gas Saver Welding And Fabrication Welding Projects

What Shielding Gas Should I Use When Welding Aluminum

What Shielding Gas Should I Use When Welding Aluminum

The Variety Of Shielding Gases Used In Arc Welding Can Be A Confusing Topic However The Use Of An External Shielding Gas Is Welding Arc Welding Welding Wire

0 comments:

Post a Comment