I then used the Eastwood TIG 200 to weld the cap to the endtanks. The best solution will be entirely dependent on where the leak is.

J B Weld For Radiator Repair Jbweld Com Worldsstrongestbond If You Can T Fix It With Duct Tape You Can Probably Fix It W Radiator Repair Diy Repair Radiators

How to Fix a Leak in an Aluminum Radiator.

How to weld aluminum radiator. Basically a thicker plate with a good amount of linear inches of weld on it. I cut a piece of aluminum plate to size then sanded it with a belt disc sander until it was a tight fit with a slight bevel. Preheating the rod will enable the flux to adhere to the rod for easy application.

2 6 mo ago. Make sure you have even pressure all along the tank and set the vice grip at a certain gap and keep it the same all the way around the tank. Before I laid the final weld sealing the two halves of the end tank together I took some high temp waterproof epoxy and sealed the edges around where the plate sat near the coils.

Tap to unmute. Be sure not to directly heat the metal or hold the torch steady as this may cause the aluminum radiator to overheat and melt. Im trying to weld up cooling tubes on an aluminium bike radiator ive cut up to fit round the exhaust.

If you weld tabs or brackets to the radiator I would weld on a re-pad reinforcing pad. This should set the tank properly on the gasket. Also keep out of harms way where the kids an animals cannot get hold of it.

Im new to welding aluminium so got some 09mm and 07mm off cuts got some ok welds and was even able to weld up the edges I had some practice on an old radiator id cut up and it wasnt. The two main fixes to repair leaking radiators are to either weld the offending leak or use an epoxy like JB Weld to fill the crack or hole. It is to be mixed with alcohol that acts as a thinner.

These steps can be applied for repairing plastic radiator with epoxy and also the repairing aluminum radiator with epoxy. Put the vice grip on the crimp and squeeze shut pushing down on the plastic tank. Remove the flux with water and a wire brush and the end result is a repair that is 30000 psiin a matter of minutes with pennies of material.

The radiator has to be put down with its taped side facing downwards. After that the ingredient of the patch should be prepared. When it comes to aluminum radiators welding is difficult and epoxy is a cost-effective way to repair it.

Ive done this once 2 years ago and it held up just fine for well 2 years. Aluminum welding rods play the role of filler material in welding. Auto Repair Tips.

Not sure about your radiator shop but a good TIG welder can easily weld thin aluminum. Using The J-B Weld. To repair most copper and brass radiators all that is required is a clean surface and some solder.

The easiest way Ive found to locate a leak is to submerge the. Im doing it again tomorrow because the JB Weld eventually just gave out. Below is a guide to applying radiator epoxy to repair and seal cracks in your radiator.

How to Fix a Leak in an Aluminum Radiator - YouTube. Apply the rod continuing to broadly heat the punctured radiator. A common feature of aluminum radiators is an epoxy seal around the tubes where they enter the header.

Then weld the tabs or brackets to these. However epoxy can be hazardous so you will have to work carefully. 3 Best radiator repair epoxy to get on Amazon No 1.

However for an aluminum radiator repair youll need gaskets epoxy aluminum welding various plastics nylon and crimping equipment. The powder flux works synergistically with the aluminum filler rod and acts as an exact temperature guide turning liquid when the base metal has reached the 600F working temperature. J-B Weld 2120 Radiator.

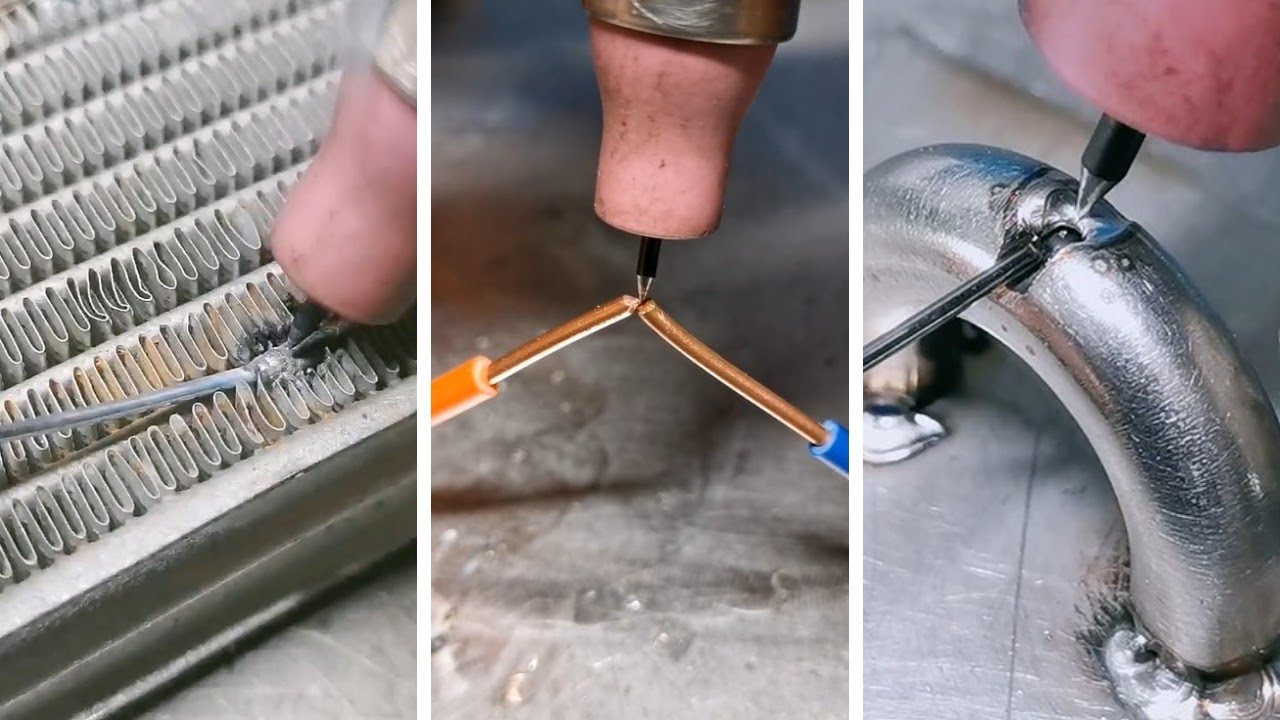

Auto Repair Tips. How to weld aluminum with a propane torch and low heat aluminum welding rods fix your radiatorHere is a link to a propane torch head pencil flame at Amazo. You can weld cracks or holes aluminum radiator through JB weld super alloy 1 aluminum radiator repair epoxy and soldering aluminum radiator.

Clamp up the tubing and start heating the aluminum with a propane torch. Check out this video on Plastic tank radiator repair. The J-B Weld is the perfect aluminum welding solution.

Aluminum will start to melt at 1200deg Fahrenheit but the brazing rod will melt at around 700deg so we want to get the aluminum hot enough to melt the rod without melting the tubing. Getting the tubing hot enough may take 4 to 5 minutes. That way if the welds on the tabs break loose you will not create a leak.

The patch can be made using either the J-B Weld or the J-B Kwik. You might be better to look for a welding shop as your chances of finding a good aluminum welder are going to be much better there than at a radiator shop unless they specialize in aluminum radiators. Begin by gently heating the rod and dipping it into the powder flux.

Radiator For Toyota Hiace Pickup Radiators Toyota Hiace Aluminum Radiator

Radiator Fmic Set Up Welding Aluminum Welding And Fabrication Welding Works

32mm 1 25 Id Aluminum Radiator Weld On Filler Neck With 1 Radiator Cap Radiator Cap Aluminum Radiator Aluminum Fabrication

Champion Aluminum Radiator 3 Row For 1965 1966 260 289 Mustang Aircraft Grade Aluminum 2mm Thick Tanks Fittings Fully Aluminum Radiator Mustang Radiators

Diy Radiator Kits Radiators Welding And Fabrication Aluminum Radiator

1 1 4 1 25 Aluminum Weld On Radiator Filler Neck With Radiator Cap Ebay Radiator Cap Billet Aluminum Weld

How To Weld Aluminum With A Propane Torch And Low Heat Aluminum Welding Rods Fix Your Radiator Youtube Welding Rods Aluminum Welding Rods Welding

Cold Welding Machine Repairs Car Radiator Precision Tig Cold Welding For The Welder And Factory 4 Youtube Welding Machine Welding Tig Welding Machine

Opening Weld On Aluminum Radiator Filler Neck 1 1 4 And Https Www Amazon Co Uk Dp B07k9xdjgb Ref Cm Sw R Pi Radiator Cap Aluminum Radiator Car Radiator

0 comments:

Post a Comment