Such an endeavor will leave you with a quick extinguished high-carbon steel weld. How can you weld cast iron with a wire feed welder.

However welding cast iron requires the material to already be.

How to weld cast iron with wire feed. Cast iron can be welded with mild steel wire. The electrode is inserted in the machine while the welder presses the trigger. Generally metals with weak tensile strength are affected by thermal contraction easily.

This is the most effective and frequently used technique. If you cant preheat the whole part try to at least warm the weld area up to 100 degrees. 2 Weld patches in place using short welds about 1 inch 25 cm long each.

Among them is wire feed welding. Because of its chemical makeup cast iron is very prone to cracking when heat is applied. Aug 8 2020 - Further there are many techniques for welding cast iron.

We ship worldwideCall us. When you weld cast iron materials with wire feed MIGs they often become brittle. Its a good option to minimize the extreme heating and cooling of the electric welding processes and its easier to maintain the temperatures of the components with it.

At this temperature the iron inside the metal gets stretched preventing it from cracking. Set up and start a survey of basic safety precautions needed during welding in your welding workstation. You can heat the casting anywhere in the range of 500-1200 degrees before welding dont go beyond 1200 degrees Fahrenheit.

Ad Apply To Mast Harness Processing Need Small Occupation Area Conwenient To Move. We supply Monel 400 60 Inconel 112 welding rods filler wire. Using the methods discussed above weld the studs in place and cover the entire surface of the break with weld deposit.

Ad Apply To Mast Harness Processing Need Small Occupation Area Conwenient To Move. A wire feed weld is a complex machine connected to a roll of rod interconnected to a gun. If you preheated the part wrap the whole component up after welding.

Make certain to check the parts altogether to guarantee there are no pressure breaks or different indications of damage. That leads to the flow of the shielding gas while the rollers turn to action. Stocks in huge qty.

We supply Monel 400 60 Inconel 112 welding rods filler wire. Ad Nickel Alloy Electrodes supplier stockist. If the cast iron object is really big preheat as much of the area around the area to be welded as possible.

View more Cast Iron Welding How-To articles. Cast iron welding process With MS MIG wire. Turn on the MIG welder and Measure your metal.

You will more likely than not end up with Martensite weak and non machinable hard. It will be counter-productive to shrink and crack the cast irons crevice with excess heat. Ad Nickel Alloy Electrodes supplier stockist.

Contact our experts now. Oxy-acetylene welding is another option frequently used to weld cast iron. When you turn on the gun there is power production and the currents start flowing.

Generally preheated welding is performed by heating the cast iron from 500 to 1200 degrees. Meanwhile the shield gas rushes through the weapons tip while you continuously feed the wire until the weld turns off. How do you weld cast iron with a wire feed welder.

Instead use filler rods to pre-heat and braze the cast iron piece. Metals such as wrought iron or mild steel can simply be welded with minimal preparation. Jun 11 2013 - Welding on cast iron is a bit different than welding on most other metals.

If the piece is small simply preheat the entire thing. Brazing isnt really welding as it doesnt fuse the metal as a weld does. We ship worldwideCall us.

Once a good weld deposit is made the two sides of the crack can be welded together. Stocks in huge qty. Contact our experts now.

Repair cracks and rips by attaching a cast part that serves as a patch between intact parts of the cast iron. To begin it employs the use of a fire welder machine and a wire feed welder electrode. Weld the cast iron very slowly stopping every 1 to 2 inches in order for the iron to cool a bit in between welds.

When activated various components come together to create a robust single weld. View Cast Iron Stick Electrodes. MIG Welding Cast Iron to Mild Steel with 308L Wire Step 1.

One is called preheated welding and the other is called non-preheated welding.

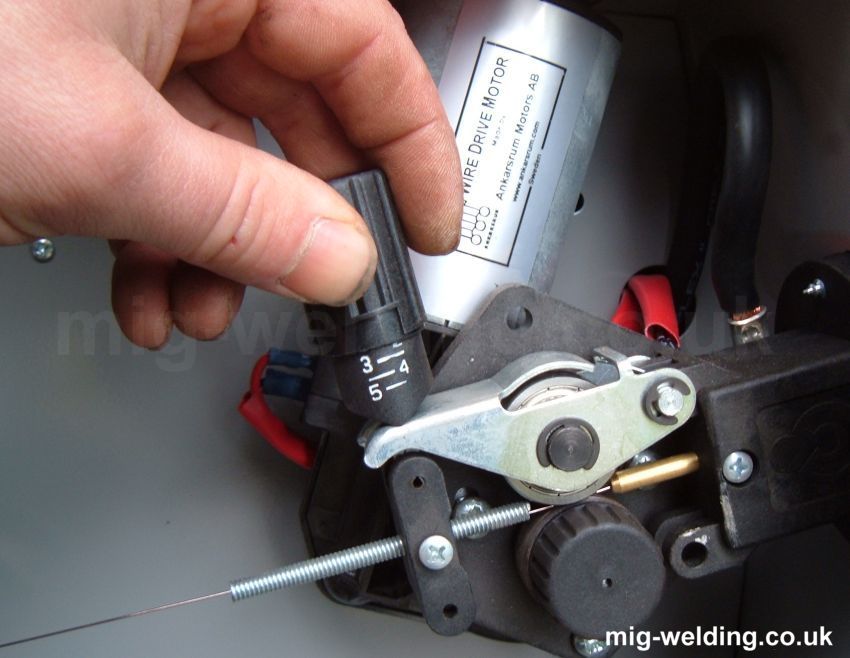

Installing Mig Wire And Setting Wire Feed Tension

Mig Welding Broken Cast Iron Youtube

Can You Weld Cast Iron With A Wire Feed Welder Let S Find Out

Can You Weld Cast Iron With A Wire Feed Welder Welding Cast Iron Wire Feed Welder Cast Iron

Installing Mig Wire And Setting Wire Feed Tension

Installing Mig Wire And Setting Wire Feed Tension

Cast Iron Welding Repair Using Flux Core Wire Youtube

Can You Weld Cast Iron With A Wire Feed Welder Welding Troop

Installing Mig Wire And Setting Wire Feed Tension

0 comments:

Post a Comment