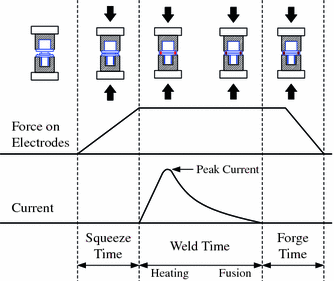

Because of this ability to rely on stored energy these projection welding devices have welding times that are short and concentrated around 12 milliseconds as opposed to about 100 milliseconds on a typical resistance welding machine. Projection welding involves heating the area as it collapses under pressure.

Process Parameters In Resistance Projection Welding For Optical Transmission Device Package Springerlink

Makes the weld water tight.

Projection welding can be considered as a mass production form of. As such they are useful for planned mass production. Heat is concentrated at the projections which permits the welding of heavier sections or the closer spacing of welds. Lancaster in Metallurgy of Welding Sixth Edition 1999 435 Braze welding.

All of the above. This process is a resistance welding process in which two or more than two spot welds are made simultaneously by making raised portions or projections on predetermined locations on one of the workpiece. This welding process is also used for the fan covers and hollow metal doors.

The electrodes used are of disc or roller shape. In a mass production environment such a time differential can really make an impact see Figure 1. Applications of Resistance Projection Welding.

MIG welding process is becoming increasingly popular in welding industry because of - a Its easy operation b Its high metal deposition rate c Its low initial cost d Both its easy operation and its high metal deposition rate 6. Resistance to heat being confined to the projections welding between the parts takes place by the application of adequate pressure at the appropriate time at these points of contact. Projection welding is a type of resistance welding that focuses current and force to a single point or line at the beginning of a weld.

Projection welding is particularly applicable to mass production work and is quite suitable where many spot welds are required in a restricted area. MIG welding process is becoming increasingly popular in welding industry mainly because of. Gas welding can produce a hot flame of temperature about 3000-3500 ⁰C.

PROJECTION Welding_resistance machines of the press type tend to be custom made or at least must be capable of accommodating the design of the workpieces. Projection welding can be regarded as a mass production form of welding. Typically laser welding has been successfully used for welding of concision resistant steels and titanium alloys in which high quality welds have been produced in sheets of thickness 0-1 to 2 mm.

It was originally developed for the repair of cast iron parts and is still useful for this purpose because the thermal cycle is less severe than in normal fusion. In gas welding acetylene is commonly used as fuel gas which mixed with proper proportion of oxygen in a mixing chamber of welding torch. This results in new challenges for resistance spot welding such as joining of two press-hardened steels with an aluminium.

The engineering components are compact constructions usually with high degree of symmetry which can normally be taken to the welding machine or installations for fabrication. Welding heavier materials that cant be spot welded. Cross wire welding is a type of projection welding that offers advantages such as.

How does it work. Precision control in rapid mass production. Projection welding is a modification of spot welding in which the weld is localized by means of raised sections or projections on one or both of the workpieces to be joined.

These projections act to localize the heat of the welding. The concept of using a forge to heat or melt metal has been used for millennia. Projections are small protrusions obtained in sheet metal by forming the material with a die under a press.

Makes the weld air tight. Con created with nitro PDF professi. Most mass production components fall in this category.

In gas welding the joint can be made even. Another benefit is that it has a fairly low price point and works well for mass production processes. Figshows the projection welding.

Braze welding or bronze welding is a fusion-welding process that utilizes 6040 brass as a filler metal with brazing-type fluxes to aid wetting. It is also expected to be used in high quality precision work as in aerospace industry and high speed mass production applications as in automobile industry. Projection welding is mostly used for mass production.

Lower electrode efficiency and maintenance. This welding process is beneficial because it can be used on any joint shape and can work with nearly any type of thermoplastic polymer. Furthermore different coating concepts and materials are used 23.

It has many applications such as. Projection welding can be considered as a mass production form of_____. One of the main differences between conventional sheet-to-sheet resistance welding and projection welding is that projection welding is a dynamic process involving considerable movement of the upper electrode.

The automobile industry uses projection welding to a very large extent. Projection welding is a resistance welding process for joining metal components or sheets with embossments by directly applying opposing forces with electrodes specially.

Process Parameters In Resistance Projection Welding For Optical Transmission Device Package Springerlink

Solved Projection Welding Can Be Considered As A Mass Production Form Of Self Study 365

Process Parameters In Resistance Projection Welding For Optical Transmission Device Package Springerlink

Resistance Projection Welding 2018 04 05 Assembly Magazine

What Is Projection Welding Working Principle Advantages Disadvantages And Application The Welding Master

Projection Welding An Overview Sciencedirect Topics

Practice Quiz On Electric Welding Welding Construction

0 comments:

Post a Comment