Powered by a vision to blend power saving with aesthetics Artech has today germinated into a force to reckon with in the field of resistance welding. This can be arranged either at your facility our at ours.

Resistance Welding Training Spot Projection Seamwheel Sd Service

Projection included angle should normally be 90.

Projection welding training. Air systems Cooling system Tooling and electrodes Maintenance Control parameters Quality Weld. Some of the details we cover. Ad Learn Welding Online At Your Own Pace.

Start Today and Become an Expert in Days. We also offer educational programs and training. One of the main differences between conventional sheet-to-sheet resistance welding and projection welding is that projection welding is a dynamic process involving considerable movement of the upper electrode.

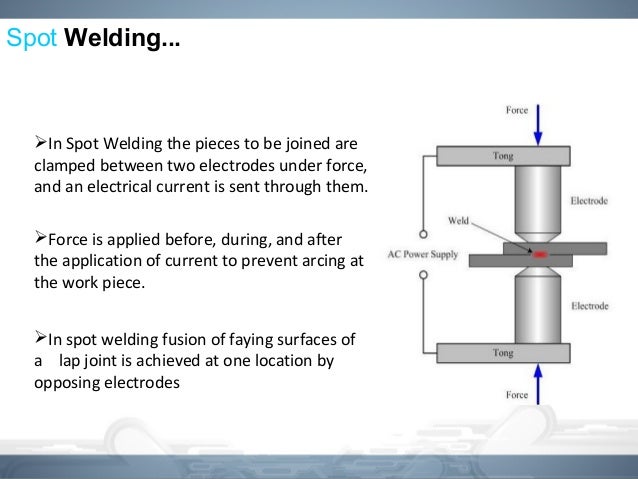

Join Millions of Learners From Around The World Already Learning On Udemy. Metals are heated and coalescence is achieved notthrough the use of an arc but through the metalsresistance to electrical currents passing through themas they are held together with pressure by electrodes. In modern welding and related processes and to provide the welder with a source of practical information on the right solution to specific onboard welding problems.

A recess adjacent to the projection is sometimes used as a spit trap. Resistance Projection Welding RPW is developed by introducing high electrical resistance at a joint by embossing one or more projections on the surface to be welded Weld nuggets are similar to spot welding Fig. One variation of spot welding process is called Projection welding process.

In this process at least one metal part has projections or depressions made by some previous pressing operation. A Resistance projection Welding bA welded bracket c d Projection welding of nuts r threaded hosses and stack 21. Projection Welding In Projection welding size and shape of individualwelds are determined by the presence of projectionsembossments or intersections on the metals to bejoined.

The Solenoid Valve is an electrically operated air valve in the compressed air line connected to the air cylinder on the welding machine. Processes 21 22 23 25. Spot and Projection Welding - Artech Welders Private Limited took roots in 1994 with the dream of manufacturing Capacitor Discharge CD projection welding machines.

Projections are dimples or bumps that are pressed or machined into material at the location where the weld is to be made. Avoid positioning the projection on the components edge. Projection height is typically 1 to 2mm depending on sheet thickness and weld strength required.

Welding and Micro-welding 50-60Hz Medium Frequency 1000Hz 2000Hz Brazing by resistance welding. Resistance Welding training spot projection seamwheel butt to butt. If less heat is needed in the joint or when welding to thinner sheet the.

Practical welding on customers machines using sample material. The other part and these projections contact each other. Join Millions of Learners From Around The World Already Learning On Udemy.

Projection welding is a type of resistance welding that focuses current and force to a single point or line at the beginning of a weld. We can train as many people as you wish with hands-on or classroom environments. Experience gained from user contact and welding training of crewmembers showed that documentation aimed specifically at on board welding solutions was needed.

Ad Learn Welding Online At Your Own Pace. Theory of resistance welding carried out in a quiet room using blackboardwhiteboard overhead projection or optical projectors screens as available. When projection welding high impact will damage the projection before welding and result in poor projection welds even when all other settings are correct.

Projection welds developed via the resistance welding RW process use the design or shape of the part to make discreet individual-point contacts to concentrate the current during welding. Ad Find China Manufacturers Of Welding Wire. In most applications one of the workpiece surfaces features multiple small formed projectionsround dimples elongated ridges or rings or the extended corners of weld nuts.

Ad Find China Manufacturers Of Welding Wire. When the welding control applies voltage to this valve. Projections promote heat balance extend electrode life and ensure a consistent current path ensuring more reliable and consistent welds.

Start Today and Become an Expert in Days. Projection welding is a resistance welding process for joining metal components or sheets with embossments by directly applying opposing forces with electrodes specially designed to fit the shapes of the workpieces. Usually the training is split into two periods.

Welding Defect Analysis Fti Sheet Metal Forming Simulation

Projection Welding Facts And Fundamentals Metalforming Magazine Article

Rw Resistance Welding Training Rsw Spot Weldind Process 21 Projection Welding Process 23 Resistance Mash Seam Welding Rmsew 22

Aws Bookstore Aws Whc3 02 Projection Welding

Resistance Projection Welding Resistance Welding Huys

0 comments:

Post a Comment