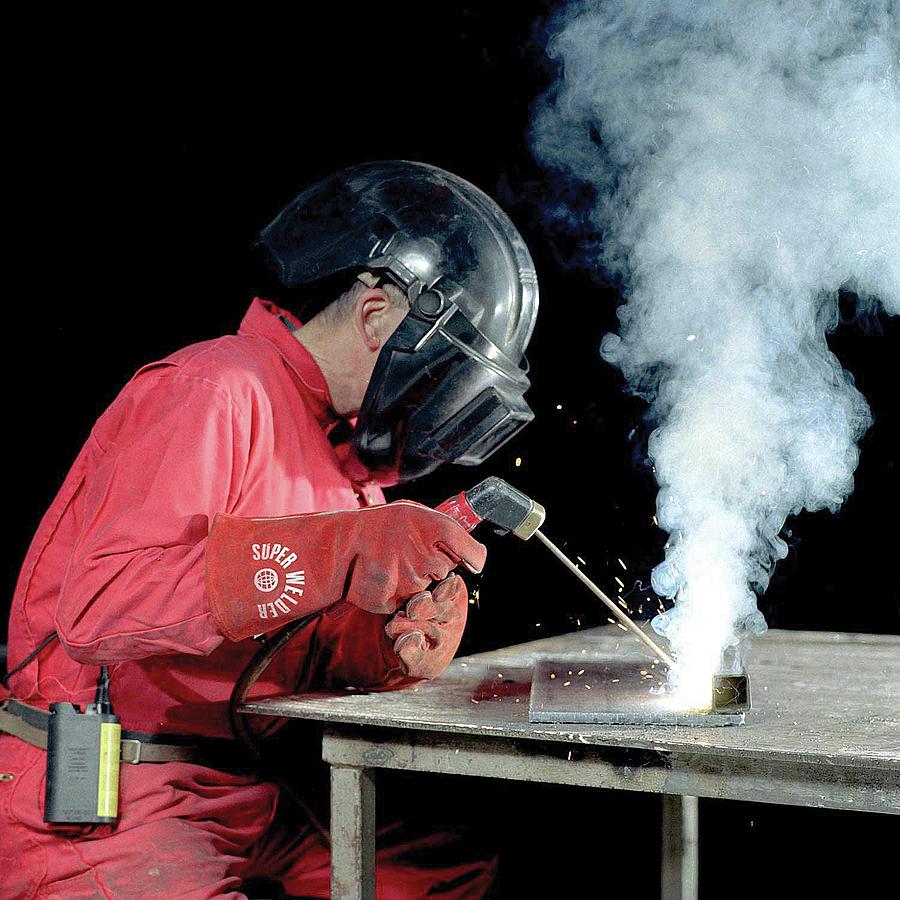

Small battery-powered air samplers can be clipped to the welders belt or apron with a sampling line to a collecting filter clipped to the collar or shield. It can be done with the help of a small battery sampler attached to the workers belt.

Welding Fume Monitoring And Assessment Queensland Haztek Pty Ltd Occupational Hygiene Health And Safety

Testing for welding fume hazards such as monitoring or personnel samplingtesting can be performed by a Certified Industrial Hygienist or an Industrial Hygienist.

Testing for welding fumes. Welding Fume SamplingTesting. The industrial use of welding is highly labour intensive labour accounting for 80 to 90 per cent of production costs for all but the most automated processes. Use of welding fume data for the assessment of exposure Compliance with Regulation 6 of the COSHH Regulations will be ensured if the occupational exposure standard for particulate welding fume does not exceed 5 mgm3 provided exposure to other toxic constituents of the fume which have lower occupational exposure limits are adequately controlled.

Monitoring welders to determine exposure is relatively easy. A Certified Industrial Hygienist by virtue of training education and experience has demonstrated the ability to recognize and test for welding fume hazards and to recommend appropriate controls. LCS Laboratory Inc offers air quality tests for welding fumes.

A simple urine sample can provide information about an individual workers exposure to the metals. You can control risks to health from welding fumes by. Having an exposure assessment report from the competent staff at K2 will show employees they are in a safe work environment and provide evidence that you are making the right steps to improve the workplace.

This fact sheet discusses welding operations applicable OSHA standards and suggestions for protecting welders and. WHS Regulation 49 requires a Person Conducting a Business or Undertaking PCBU at a workplace to ensure that the airborne concentration of welding fume does not exceed the exposure standard. The welding process produces visible smoke that contains harmful metal fume and gas by-products.

Monitoring for welding fume and gases may be required as part of the assessment of risk where it is necessary to obtain a quantitative estimate of exposure. Welding fume can also cause asthma and many other health conditions. One common industrial activity that often generates an Improvement Order is welding and exposure to welding fumes.

Biological monitoring can assess exposure by all routes inhalation ingestion and skin absorption. Workplace Safety and Health Division may issue an Improvement Order to your company for a chemical and biological substances or a workplace exposure assessment. Using alternative cold joining techniques.

WHS Regulation 50 requires that atmospheric testing is carried out to confirm the compliance with the exposure standard for welding fume. Welding Fume Monitoring Testing Monitoring is undertaken to determine the concentrations of welding fume and gases that workers breath while work is undertaken. As a turn-key package you will receive portable battery-operated air sampling pumps sampling cassettes laboratory analysis of your samples using the NIOSH 7301 method and a formal laboratory report stating the airborne concentrations of 19 common heavy metals.

HSE has issued a safety alert about the health risks of welding fume. Welding in a way that produces less fume. Monitoring welders for welding fume exposure is relatively easy and should be considered favorable practice.

Gases during Welding Welding joins materials together by melting a metal work piece along with a filler metal to form a strong joint. Ensure RPE wearers are clean shaven and provide face-fit testing for them. Winnipeg Air Testing can sample for a variety of.

For welding outdoors local exhaust ventilation will not work so workers should use suitable RPE to control exposure. Cinnaminson NJ February 07 2017 The Occupational Health and Safety Administration OSHA describes welding cutting and brazing as hazardous activities that pose a unique combination of both safety and health risks to more than. EMSL Analytical Inc.

Provides testing services and sampling supplies to identify welding fumes and gases to safeguard workers. Fumes and gases 1 Introduction Welding is the principal industrial process used for joining metals. All welding fume can cause lung cancer so you must put controls in place.

This welding process generates a substantial amount of fumes because of the high electrical currents and the flux-cored electrode. Welding Fume Testing and Sampling. Hazardous welding fumes and trace metals can be inhaled by employees without adequate protection during welding and hot work.

Welding Fume Hazards Testing Sampling For Welding Fumes Atlantic Environmental

Managing Welding Fumes On Farms All You Need To Know Farmers Weekly

Welding Fumes Exposure Testing Photograph By Crown Copyright Health Safety Laboratory Science Photo Library

Welding Fume Hazards 2016 06 26 Safety Health Magazine

Working Safely With Welding Fume A Summary Of Solutions And Risks

Limit Values For Welding Fumes Let S Count The Particles

Managing Welding Fumes On Farms All You Need To Know Farmers Weekly

Welding Fume Hazards Testing Sampling For Welding Fumes Atlantic Environmental

Dealing With Welding Fumes Resources American Welding Society

0 comments:

Post a Comment