This occurs when the imperfections exceed the acceptance criteria specified in the standard. With 3D technologies the borescope system computes 3D coordinates at the cursor positions to perform the.

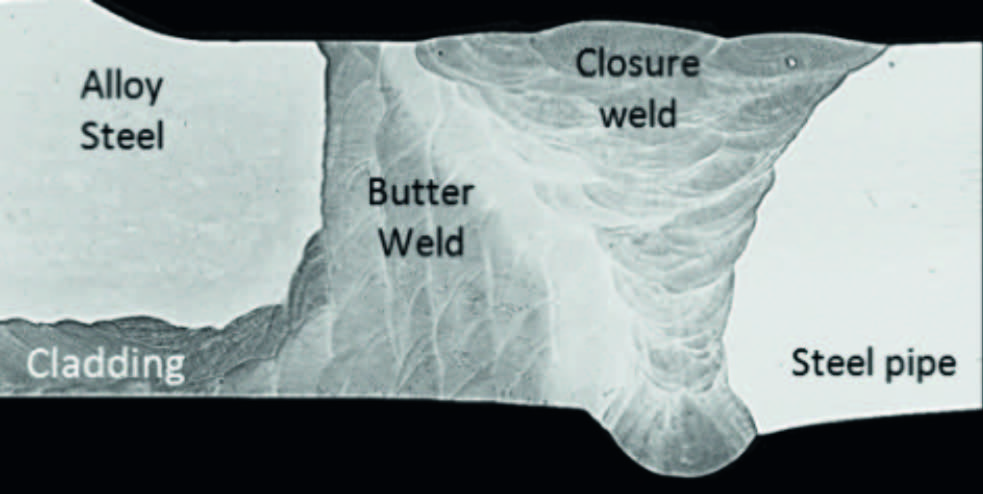

Easy Ultrasonic Phased Array Inspection Of Corrosion Resistant Alloys And Dissimilar Weld Materials

Main responsibilities of a welding inspector are.

Welding borescope meaning. Boroscope Videoscopeis an instrument or device which is used in the review and inspection of piping interior surface and weld joints of the pipes. A borescope is used to verify that the weld is fully penetrated and to identify any defects or contamination. Quality control inspection for defects at the point of exploitation.

The industrial borescope is used as a non-destructive test. It is the contemporary practice of pharmaceutical industry to use boroscope for documentation of orbital welding joints for inspection and review purposes. Experienced well-trained weld examiners was recognized.

It is an economical activity as it doesnt require any costly equipment. Portable borescopes are key to quickly and easily inspecting welds and can offer full image and video documentation and storage. If Type 316 and Type 6Mo is welded with Nb-alloyed consumables above 05 and the min.

Any deviation from the ideal weld. Records of how often various types of defects occur must show when changes in welding procedures are necessary detecting poor welding practices or when the welders or welding operators should be re-qualified. The basic steps include cleaning or preparing the surface to be inspected applying the penetrant removing the excess penetrant and then documenting.

Welds not meeting OD standards examined by borescope or other suitable means - Welds shall be full penetration - No cracks undercut crevices or embedded or protruding material - No excessive discoloration AWS D182 Slag-like surface imperfections 116 are unacceptable and those. And manifold structures welding. Fluorescent Penetrant Inspection FPI is a Non Destructive Testing NDT technique where a fluorescent dye is applied to the surface of an impermeable material to clearly identify surface defects.

Based on this premise this paper presents training methods that. It must be carried out by a well experienced inspector. The quality and color of the weld bead as well as residual deposits on the welding can be visually inspected with our color videoscopes and their smooth coated insertion probes are designed to prevent polished pipes from surface scratches.

WM means weld metal centre line and FL means fusion line. In the late 1970s the American Welding Society developed its Certified Welding Inspector CWI program to meet this need. Design temperature is below - 29 C impact testing shall be carried out at -105 C or at minimum design temperature.

Boroscope Videoscope is an instrument which is used for the inspection of piping internal surface and weld joints. 823 Undercut Melting away of the side wall of a welding groove at the edge of a layer or bead or a reduction in the base metal thickness at the fusion line 824 Visible Porosity Gas pockets or voids free of any solid material. Provide a section on use of borescopes and a classification of the different types available.

Inspectors need formal training to ensure borescoping is an effective non-destructive means of visually inspecting internal areas to detect distress in gas turbine engine and aircraft components. Necessitate repair of the weld or adjustment of the welding process parameters or both. In practice this means specifying good human factors practice primarily for the borescope.

BS EN ISO 6520-1 provides the following definitions. Weld defects include a lack of fusion to the base metal root-pass cracking and incomplete penetration. 421 Visual Acuity One of the more obvious prerequisites is that the VT examiner should have sufficient visual.

This project was designed to apply human factors engineering techniques to enhance the reliability of inspection of rotating engine parts using borescopes. 3D Phase Measurement can quantify the weld. Section 493 provides a brief overview for this program.

Visualize areas in tubing without having to dismantle processing equipment. Pores may be individual clustered. In order to ensure the quality of pipe welding industrial endoscopes provide strong support for the inspection of the outer surface of welded parts.

It is the current pharmaceutical industry practice to use boroscope for documentation of orbital welding joints for inspection. The Welding Inspector must judge whether the weldments inspected are conform to the specifications. The advantages of borescope inspection used in Pharmaceutical Plants.

Other NDT methods can also be employed. No single values shall be below 75 of the average requirement. Visual examination of weld joint is an important activity carried out to check the integrity and soundness of the weldment.

Traditional borescope-measurement means capturing a 2D image using a measurement tip then positioning cursors on that image to perform the measurement.

Basic Weld Symbol More Detailed Symbolic Representation Of Weld Table Of Weld Symbols Supplementary Symbols Proyek Pengelasan Modifikasi Mobil

How To Read Welding Symbols Welding Projects Welding Training Welding

Tips For Using Fillet Weld Gauges

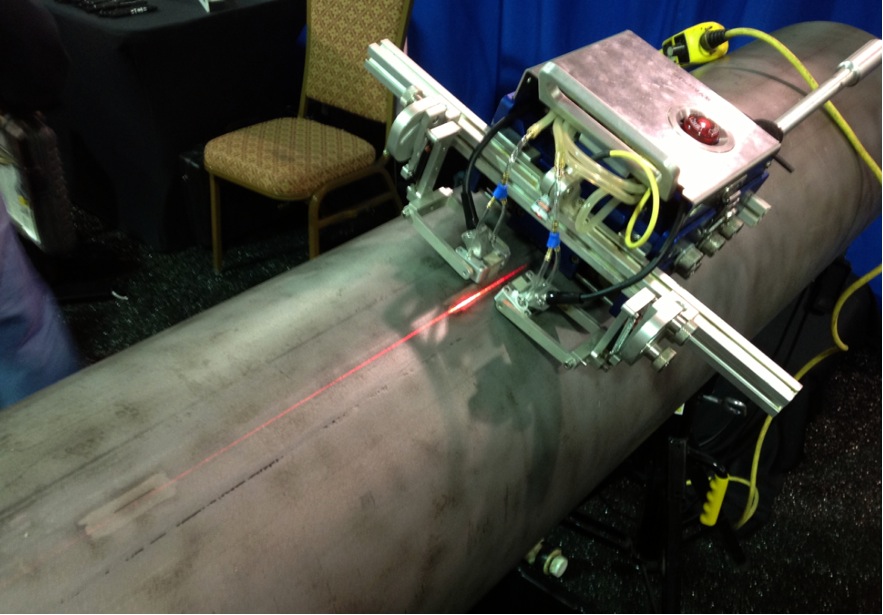

In Service Inspection Of Erw Welds Using Pa Angle Beam Weldrover Scanner

10 Criteria For Industrial Borescope Inspection Defects Borescope Camera

0 comments:

Post a Comment