Working principle of TIG welding. The support of shielding gas uses this process.

Tig Tags Welding Leaving Certificate Engineering Notes

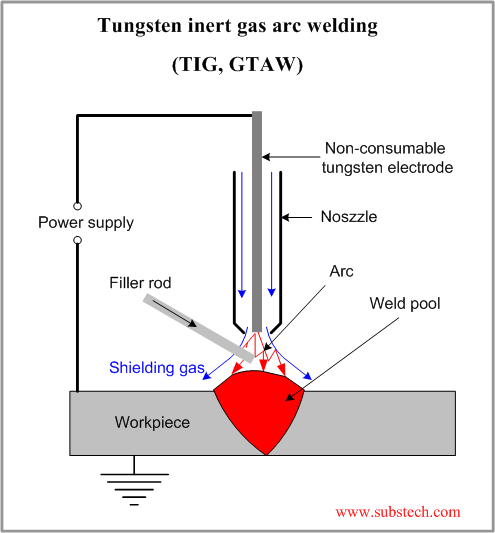

Tungsten Inert Gas TIG welding uses the heat generated by an electric arc struck between a non-consumable tungsten electrode and the workpiece to fuse metal in the joint area and produce a molten weld pool.

Principle of tungsten inert gas welding. TIG stands for tungsten inert gas welding or sometimes this welding is known as gas tungsten arc welding. Figures show the principle of tungsten inert gas welding process. It then cools and form a solid joints.

Working Principle of Tungsten Inert Gas Welding. The consumable tungsten electrode is produced the arc to generate the required heat. The electrode in the rod is made from the rare metal tungsten and cooled and protected by an.

It is a manual welding process. Tungsten inert gas TIG welding became an overnight success in the 1940s for joining magnesium and aluminium. TIG stands for tungsten inert gas welding or sometimes this welding is known as gas tungsten arc welding.

In this welding a non-consumable electrode is used which does not melt. As with other types of arc welding the basic principle is that an electric power supply is used to create an electric arc between the electrode and the metals being melted down in the weld. Working Principle of Tungsten Inert Gas WeldingGas Tungsten Arc Welding.

The arc area is shrouded in an inert or reducing gas shield to protect the weld pool and the non-consumable electrode. A shielding of inert gas argon or helium is used to avoid atmospheric contamination of the molten weld pool. Tungsten Inert Gas welding TIG which is usually called Gas-tungsten arc welding GTAW is an arc welding process that employs the heat generated by an electric arc between a non-consumable tungsten electrode and the work piece.

There is a non-consumable electrode is used and it does not melt. In this welding process the heat required to form weld is provided by a very intense electric arc which is form between tungsten electrode and work piece. The working of tungsten inert gas welding is less complex and can be easily understood.

In this welding process the heat required to form a weld is provided by a very intense electric arc which is form between a tungsten electrode and workpiece. It operate under similar principle with MIG welding. Gas Tungsten Arc Welding GTAWalso known as tungsten inert gas TIG welding is a process that produces an electric arc maintained between a nonconsumable tungsten electrode and the part to.

The base metal and bonding materials are melted by the heat generated by an electrical current. Tig welding is also very popular as Gas Tungsten Arc Welding GTAW and it is the process of welding metals with the help of an arc. When we switch on the machine the high-frequency generator provides an electric spark.

The small intense heat source provided by the tungsten arc is ideally suited to the controlled melting of the material. Principle of TIG Welding. Hello Everyone Welcome To Engineers AcademyIn this video we will learn the Process of Tungsten Inert gas welding.

The tungsten arc process is being employed widely for the precision joining of critical components which require controlled heat input. In the TIG welding process the heat is required for forming a weld and it is provided by an intense electric arc and it is formed between a tungsten electrode and workpiece. Tungsten Inert Gas TIG welding also known as Gas Tungsten Arc Welding GTAW is an arc welding process that produces the weld with a non-consumable tungsten electrode.

A filler rod may be fed to the arc zone. In this process a non-consumable tungsten electrode is used to generate heat. The electric spark is struck between the Workpiece and the Electrode either by touching electrode by scrap material or by using a high-frequency unit.

Tungsten Inert Gas TIG welding is a type of arc welding. TIG Welding its Principle Working E. It is similar to form of arc welding process.

When we switch on the machine the high-frequency generator provides an electric spark. Tig Welding Tungsten Inert Gas Welding is a great process by which you can join the metal and putting some tungsten electrode between them. The principle Of Tungsten Inert Gas TIG Welding Process This chapter presents the principle of tungsten inert gas TIG welding process besides important components of TIG welding system and their role.

In this welding a non-consumable electrode is used which does not melt. The electric spark is struck between the Workpiece and the Electrode either by touching electrode by scrap material or by using a high-frequency unit. The full form of TIG is Tungsten Inert Gas welding or it is also known as tungsten arc welding.

Gas tungsten arc welding process and its working principle The gas tungsten arc welding GTAW is also known as TIG welding Tungsten inert gas. Gas Tungsten Arc Welding GTAW is also known as Tungsten Inert Gas TIG Welding. This process is also known as gas tungsten arc.

Gas Tungsten Arc Welding Process And Its Working Principle Techminy

Tig Tungsten Inert Gas Welding Gtaw Gas Tungsten Arc Welding Explained In Detail Withme Youtube

Tungsten Inert Gas Tig Welding Of Aluminium Alloys The Principles And The Process

Tungsten Inert Gas Arc Welding Tig Gtaw Substech

Tig Welding Definition Components Working Advantages Disadvantages Applications Pdf

Tig Tungsten Inert Gas Arc Welding Construction And Working Principle Of Tig Learn And Grow Youtube

0 comments:

Post a Comment