Combustibles are closer than 35 to the point of operation or where there are appreciable combustibles easily ignited by sparks. A Fire watch and a hot work permit are required when welding or cutting is performed where.

Hot Work Toolbox Talk Environmental Health Safety

25 Hot Work Equipment equipment that is electric or gas welding or cutting equipment used for hot work.

Welding cutting hot work safety policy. The cutter welder or hot work operator will. Performing any welding cutting andor brazing. Hot work means riveting welding flame cutting or other fire or spark-producing operation.

Hot Work Requirements Welding Cutting and Brazing January 2014 4 Hot Work Operator Responsibilities. 1917152 b Hot work in confined spaces. Anyone performing hot work must comply with the Hot Work and Welding Management.

Operators of welding cutting or other hot work equipment. Hot WorkWelding Fires Where combustible materials such as paper clippings wood shavings or textile fibers are on the floor the floor shall be swept clean for a radius of 35 ft. Developed Hot Work and Welding Management Procedures to prevent accidental fires loss of life and injury from hot work activities exposure to sparks heat or flames andor loss of property that may result from welding cutting andor brazing activities.

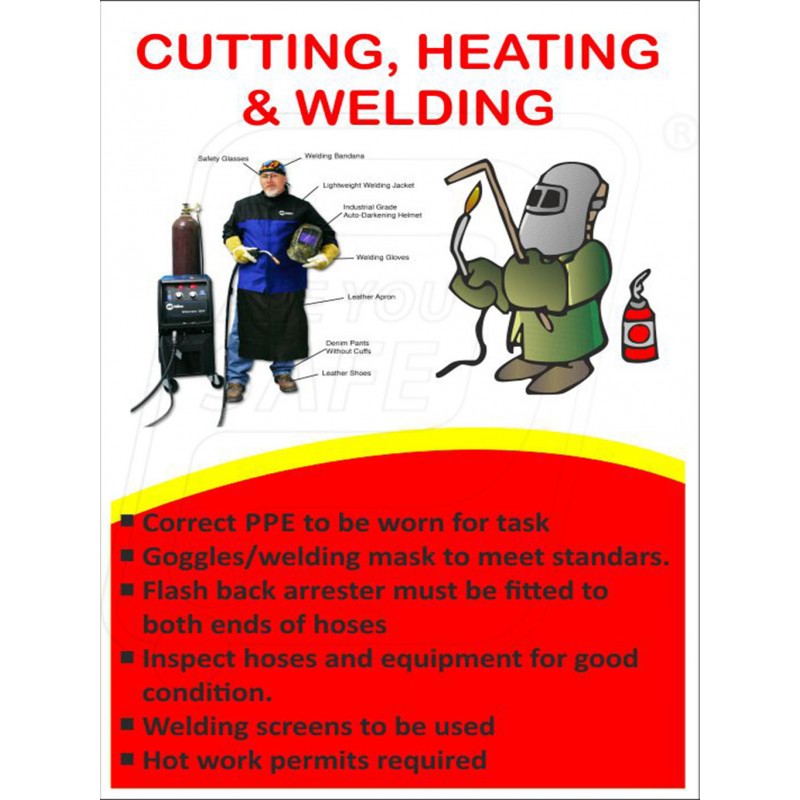

The workplace safety coordinator should conduct a PPE assessment of hot work tasks that will be performed by employees in the workplace. It presents provisions for training discussion on types of welding safe work practices and employee protection requirements. Operational areas shall have signage indicating fire hazards that.

Welding booth shall be made at Welding location. Gas testing should be done around 15 meter radius of hot work. Welding Cutting and Heating.

Work such as welding soldering cutting grinding chipping breaking hammering vehicle operation etc. Welding work on any tank vessel or piping shall only be undertaken when it has been positively isolated from all sources of flammable hazards and established that it is free of flammable vapors or substances. Hot work shall not be performed in a confined space until a designated person has tested the atmosphere and determined that it is not hazardous.

The operator shall be responsible for using appropriate safety. Safety Standards in Shipyard Employment for Scaffolds. Fire safe areas shall be documented by management.

It also presents critical details on hot work permits work in confined spaces ventilation. This leaflet is for people who use compressed gases for welding hot cutting and similar processes. Hot work permits are valid for one work shift and one task.

26 Hot Work Operator individual designated by the University to perform hot work under the authorization of a Hot Work Supervisor. The operator shall be fully qualified to perform required hot work. Hot Work Safety Dos and Donts.

Proposed Rule 6713117 March 21 2002. This safety policy and procedure provides guidelines for safely performing welding operations. Common hot work processes are welding soldering cutting and brazing.

Conduct hot work only after specific written approval from the Administrator or designee. Introduction Oxyfuel gas equipment has many uses - welding cutting heating straightening and descaling. Welding Cutting and Brazing.

Safeguards as required by this policy and made part of the Hot-Work Permit. That use an open flame or generate sparks or may generate sparks and present a potential risk of fire and explosion are categories as hot work. Extension of the Office of Management and Budgets OMB Aproval of Information-Collection Paperwork Requirements.

A document issued for the purpose of authorizing a specified activity. No welding cutting or other hot work shall be performed on used drums barrels tanks or other containers until they have been cleaned to make absolutely certain that there are no flammable materials present or any substances such as grease tars acids or other materials which when subjected to heat might produce flammable or toxic vapors. Handle all hot work and related equipment safely and perform work so as not to endanger lives and property.

Prior to performing hot work tasks employers should instruct employees in the use of PPE fire prevention and protection requirements and the safe use of weldingcutting-related equipment. Be responsible for the safe handling of the cutting or welding equipment and the safe use of this equipment during the cutting or welding process. Determine the combustible materials and hazardous areas present or likely to be present in the work.

Is required for hot work operations unless working in designated fire safe area eg. It describes the hazards associated with portable oxyfuel gas equipment and the precautions for avoiding injury and damage to property. Combustible floors shall be kept wet be covered with damp sand or be protected by noncombustible or fire-retardant shields.

Any process that can be a source of ignition when flammable material is present or can be a fire hazard regardless of the presence of flammable material in the workplace. The Operator shall be responsible for obtaining completing and returning the hot work permit See Appendix B.

Hot Work Dan Prosedur Agar Bekerja Dengan Aman Indonesia Fire Safety

Pdf Hot Work Permit Muhammad Noman Khurshid Academia Edu

Hot Work Safety Poster Hse Images Videos Gallery

Hot Work Safety Dos And Don Ts Welding And Cutting Safety Precautions Hse And Fire Protection Safety Ohsa Health Environment Process Safety Occupational Diseases

Hot Work Safety Guidelines Human Resources

Hot Work Safety Training Welding Cutting Brazing Ppt Video Online Download

Hot Work Permits Are Required Osha Notice Safety Sign Mwld804

Hot Work Permit Rules And Regulations

0 comments:

Post a Comment