Stresues on Weld Area The force tansmitted by a unitarea ofweld maybe decomposnd into shearand normal stress components fillet weld shown P Force vector 0L Stress normal to weld throat t shear stress acting perpcndicular to weld axis tI shear stress parallel to weld axis weld. Take the quiz and prove your welding.

Plastic Welding Inspection And Testing Of Plastic Welds Plastic Distributor Fabricator

Radiographic Test RT can be done in lieu of bend tests.

Welding force test. This NDT method can be used on metals which can be easily magnetized ferromagnetic. A crack would show a weakness of the weld. Everyone has to start somewhere though so if you think you might have amassed enough knowledge in your time to master our welding quiz then why not grab your gear and give it a shot.

It means the weld is performed in a ring mode by placing a steel plate below the weld site with an inch gap. The system is hooked up to a computer with a program to determine the test result. Steps in DP test.

This force is necessary to assure good electrical contact between the parts being welded and to hold the parts steady until the molten metal forming the welded joint has time to solidify. These tests and examinations are easily done and need not cost a lot of money. Magnetic Particle Testing MT also known as magnetic particle inspection MPI is a non destructive test NDT method used to detect surface or subsurface near to surface discontinuities.

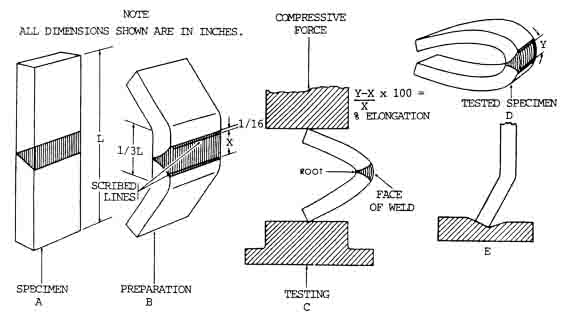

Once a suitable section of the weld is selected it is prepared for testing. The piece should bend around without cracking. STEP 3 APPLY DYE PENETRANT.

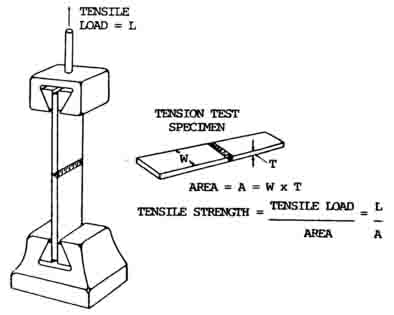

For the vast majority of cases you will only need to perform visual inspection and a fillet break test for fillet welds or bend tests for groove welds. During the application of the load the. It has been observed from tests conducted on tensile coupons containing a full penetration butt weld normal to the applied load that the welded joint had higher strength than the parent metal itself.

The ultimate shear stress TXU is Txu RxuLt 1 in which Rxu the ultimate force t the. Tension Force Tensio n Tests Tension Strength Bending Tests ducted to establish the ultimate force for the Z-direction of loading and in particu lar how T-joints resist moments. Dye penetrant test or Liquid penetrant test STEP 2 CLEANING AREA TO TO BE TESTED USING DP.

A hammer-like pendulum hits the weld area with a certain specified force. STEP 7 GIVE DEVELOPING TIME. Metals can be classified as ferromagnetic paramagnetic or.

Basically this is another difficulty level for welders in the certification process. Analysis Consider a fillet weld loaded in the X-direction in Fig. Square piece of sheet or plate with centre cut Radial and circumferential strains imposed by weld deposit Crack formed at the weld centerline is detected by visual inspection or dye penetrant inspection Crack resistance θr Centerline and.

The Tensile Strength Tests. Electrode Weld Test Force Gauge Watteredge offers a custom designed digital electronic electrode force gauge that provides a quick and accurate method to measure electrode forces as a part of an overall quality control program such as ISO 9000 or QS 9000. STEP 6 APPLY DEVELOPER OVER SURFACE.

The force transmitter is designed to measure the contact force generated between the electrodes during a spot welding operation. The third critical factor in resistance welding is the force squeezing the metal parts together Electrode Force. It is another form of a 6G test.

Fillet Weld Break Test. STEP 4 GIVE DWELL TIME. The letter R stands for restricted.

Lot or batch is subjected to destructive tests to determine if the weld process meets strength and durability requirements. This force can be seen on an impact-measuring gauge. For butt welds the most critical form of loading is tension applied in the transverse direction Fig.

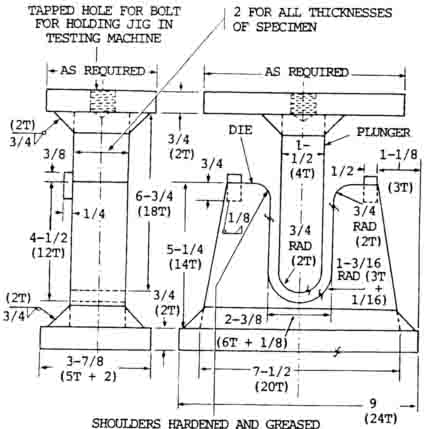

The welding process can be kept at a constant high quality by periodical testing of the electrode forces Optimization of welding tong life and servicing intervals. The test piece is then put into a bending jig and force applied to it directly over the welded area. Even an expert welder might not understand all the subtle ins and outs.

This and the Technological Bend Test. STEP 8 EXAMINE SPECIMENSURFACE. The ProLine Push Out Test Stand creates fast and repeatable tests on projection weld quality by measuring the force to break the weldThe ProLine system use.

A neatly bent strip would show the weld is as strong as the parent metal. RING WELDABILITY TEST Used to study the hot cracking of weld metal or partially melted zone It used for Al alloys and low alloy steels Test piece. If the failure rate is sufficiently low in the test samples the rest of the parts are assumed to be of good quality and are released for shipment.

Principles of penetrant testing.

Plastic Welding Inspection And Testing Of Plastic Welds Plastic Distributor Fabricator

Spot Weld Testing Methods Equipment United Testing Systems

Physical Weld Testing Destructive Nondestructive Weld Guru

Physical Weld Testing Destructive Nondestructive Weld Guru

Physical Weld Testing Destructive Nondestructive Weld Guru

A Schematic View Of A Bend Test A And An Overview Procedure Of The Download Scientific Diagram

Physical Testing Welding Positions Welding Machines And Other Weliding Cutting Systems Plasma Welding

Spot Weld Testing Methods Equipment United Testing Systems

Plastic Welding Inspection And Testing Of Plastic Welds Plastic Distributor Fabricator

0 comments:

Post a Comment