Things like contour finishes finishing. For fillet welds numbers to the left of the symbol indicate the design throat thickness leg length leg size or both design throat thickness and leg length requirements.

Skewed T Joints Between 60 And 30 Degrees

In order that the correct size of weld can be applied it is common to find numbers to either the left or to the right of the symbol.

Welding z dimension. Take a look at this link. Z a or s depending on whether the leg length or throat thickness is to be specifiedUnless otherwise instructed it is usually the leg length that is specified in which case only the z box needs to be addedIf the throat thickness is to be specified only the a box needs. As is the case with AWS A24 the size of the fillet weld is placed to the left of the weld symbol.

In the following image you see an example of an intermittent weld with 18 inch weld thickness weld length of 5 inch and a pitch of 10 inch. Z loss reduction is a dimension to account for lack of penetration to the root of partial joint penetration welds. Stress in a fillet weld.

The vector stencils library Welding contains 38 welding joint symbols to identify fillets contours resistance seams grooves surfacing and backing. The effective area shall be the ef-fective weld length multiplied by the effective throat. On the obtuse side the weld throat is smaller than what would be expected for a fillet weld of a similar leg size in a 90-degree joint and the opposite is the case for the acute sideThese factors must be considered when the fillet weld leg size is determined.

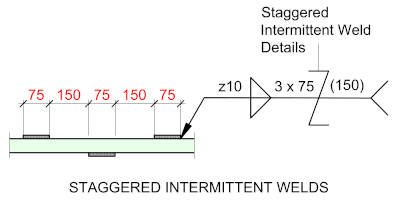

Then imitate the welds along side two but in between side ones welds not aligned with them. When identification of the weld process is required as part of the weld symbol the relevant weld process code is listed in BS EN ISO 4063. 3 When resistance seam welding extends less than the distance between abrupt changes in the direction of the welding or less than the full length of the joint the extent must be dimensioned fig.

Ad Find China Manufacturers Of Welding Wire. With the ISO system the weld size is placed to the left of the weld symbol and is preceded by the letters. If the dimension is prefixed by the letter Z it is a leg dimension.

If the size is prefixed by the letter a the dimension is the theoretical throat dimension. Ad Find China Manufacturers Of Welding Wire. There are many symbols and notations shown with fillet welds that are the same for other types of welds such as spot welds slot welds plug weds groove welds and others.

An arrow line 2. 2 When resistance seam welding extends for the full distance between abrupt changes in the direction of the welding no length dimension need be shown on the welding symbol. In addition to the length you also note the pitch of the segments.

Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding. The Z-shaped symbol with a line passing through its center displays the effect of a 7 in a mirror. Weld leg dimensionThis relationship does not hold true for fillet welds in skewed joints.

All-the-way-around weld denoted by the circle and finish contour must be flat by grinding. Intermittent weld example. Intermittent welds or also called skip welds are weld seams with unwelded spaces in between.

Z loss dimensions will vary for nontubular and tubular connections for different angles welding processes and positions. Ad High Performance Wide Range Quality Structural Adhesives for Plastic Bonding. A reference line 3.

Use it to indicate welding operations on working drawings in the ConceptDraw PRO diagramming and vector drawing software extended with the Mechanical Engineering solution from the Engineering area of ConceptDraw Solution Park. Basic Weld Symbol The weld symbol always includes 1. Weld symbols on the full reference line relates to welds on the near side of the plate being welded.

Instead weld even stitches across side one. Dont weld the full length of both sides. Length of a fillet weld shall be at least four times the nominal size or the effective size of the weld shall be considered not to exceed 25 of its effective length.

Iso Weld Symbols Structural Detailer

Chapter 5 Welding Joint Design And Welding Symbols

Zig Zag Chair Dimensions Zigzag Chairs Welded Furniture Metal Furniture Design

Iso Weld Symbols Structural Detailer

Deciphering Symbols Welding Productivity Types Of Welding Metal Working Welding

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

Fillet Weld Symbols Interpretation Of Metal Fab Drawings

Iso Weld Symbols Structural Detailer

0 comments:

Post a Comment